Very interesting, a vid of it running in the works?

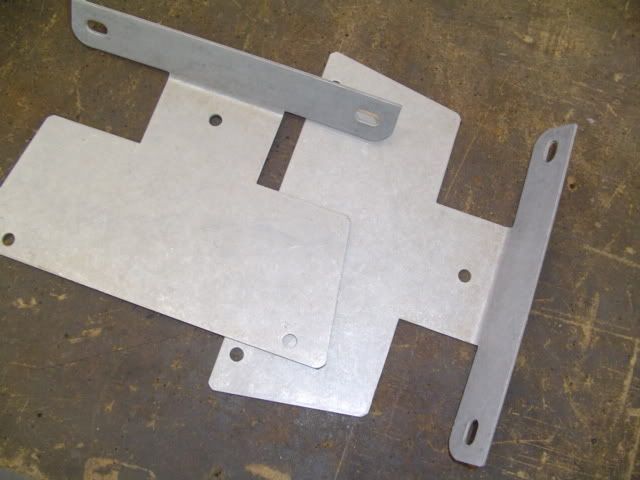

Thread: Another DIY Tumbler

Results 21 to 29 of 29

-

02-27-2008, 04:41 PM #21

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 45

Quality Type 2 Anodizing PM me For a quote!

Examples of our work here! http://s74.photobucket.com/albums/i260/125Customs/

-

02-28-2008, 07:23 PM #22

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 92

71 alum parts have been run thru the machine. I will have to line the ends of the tub as the corners of the parts are getting peended over from bumping against the unlined area.

If anyone is looking for a way to get a faux galvanized finish on alum, pink synthetic plastic rocks is the way to do it .

.

I'd say these rocks are pretty aggressive. I ran 8 tag brackets at a time for about 30 mins to get the deburr and paint prep I needed. I used a small amount of compound and kept the rocks wet. I believe the time would be reduced if the tumbling action could be improved. The parts and rocks come up from the bottom of the tub in the center and split off to each side. So instead of one big circular action there are 2 small ones. Also, the action is very slow. I'm not sure what change I will make to improve this.

The springs I am using are pretty soft. Load rating of 137 lbs and a rate of 82 lbs. Don't know if adding more would help. The axle is turning about 1000 RPM, increasing this doesn't seem like the answer. Add counterweight maybe?

-

02-28-2008, 07:25 PM #23

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 92

-

02-28-2008, 07:27 PM #24

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 92

-

02-28-2008, 07:48 PM #25

Registered

Registered

- Join Date

- Sep 2005

- Posts

- 86

A couple different things to try that may or may not get your action tumbling:

Run different rate springs on one side. This will get one side of the tub to move more than the other side, which should make it all tumble.

Tie down one side with a ratchet strap. This will have a similar effect.

-

02-29-2008, 05:58 PM #26

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 1810

Or perhaps alter the offset (phase relation) of your opposed weights.

ScottConsistency is a good thing....unless you're consistently an idiot.

-

05-11-2011, 03:13 PM #27

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 4

working video....

hi.. pls share working video....

thank you....

-

05-11-2011, 08:31 PM #28

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1041

Here's an idea I've been thinking about, but more for polishing tumbler, however it might work with a deburr tumbler... If the motor was to turn and off in a pulsing effect , it will push the media harder on the metal for a few secs or however long it's set (longer for harder metals).

Here's what brought me on to it. Sticking my hand into the corncob tumbler it's light and easy to move around. However once off try this, you hand is forced to push harder to move thru the media. Just a thought

-

07-10-2011, 06:44 PM #29

Member

Member

- Join Date

- Feb 2011

- Posts

- 0

I'd like to see this guy run, but Photobucket wants a password?? Great job, BTW!

Similar Threads

-

Which type of tumbler is better for Al?

By bob1112 in forum Mass finishing equipment/media/strategiesReplies: 44Last Post: 04-27-2011, 05:10 PM -

DIY Vibratory Tumbler

By mxtras in forum Mass finishing equipment/media/strategiesReplies: 15Last Post: 10-17-2007, 06:53 AM -

Vibratory or tumbler for slag?

By BallisticFab in forum Mass finishing equipment/media/strategiesReplies: 3Last Post: 03-05-2007, 10:14 PM -

Vibratory tumbler comparison

By mtechserv in forum Mass finishing equipment/media/strategiesReplies: 3Last Post: 02-10-2007, 03:57 PM -

Tumbler vs. Hand finish/polish

By DAB_Design in forum MetalWork DiscussionReplies: 7Last Post: 07-08-2004, 11:03 AM

Reply With Quote

Reply With Quote