Results 1 to 20 of 114

Hybrid View

-

11-29-2008, 04:02 AM #1

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

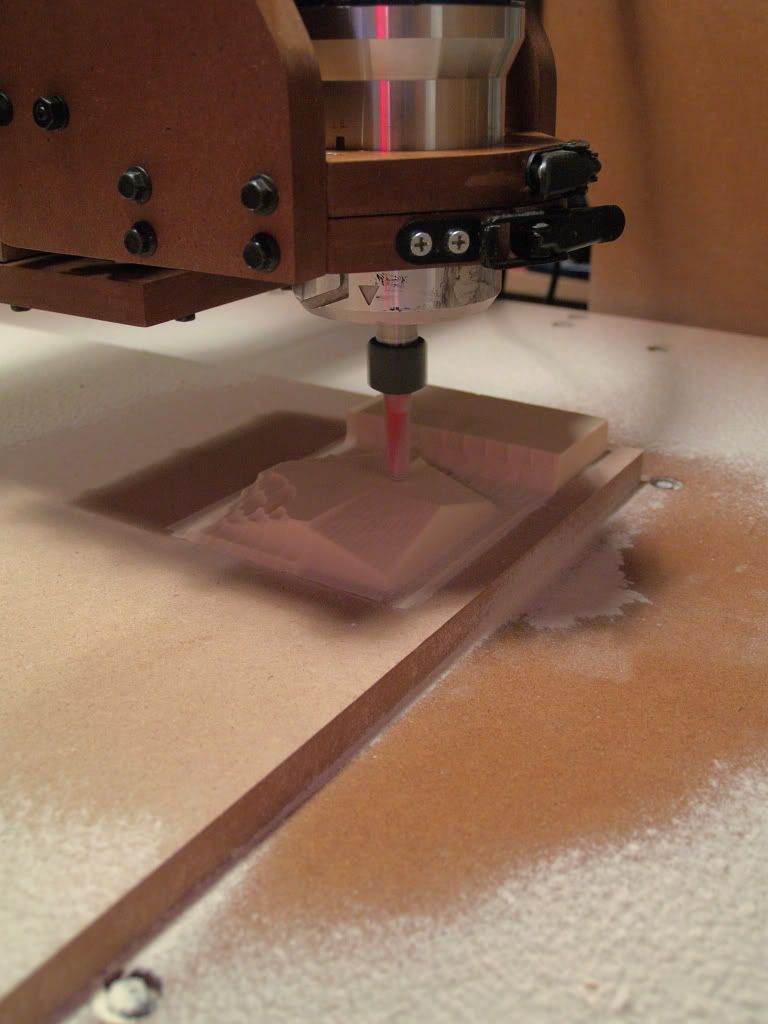

First cuts with the machine!

First cuts with the machine!

-

11-29-2008, 08:40 AM #2

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 1147

Impressive planning and execution. Way to go. I hope you post more vids. Were there any problems that you ran into that you may want to share with a noobie like me?

-

11-29-2008, 05:25 PM #3

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

I didn't really run into a lot of problems.. One major suggestion I'd have is to go with 1/2" lead screws... I went with 5/8"-8 2 start (4 TPI). There is huge support for 1/2" Like the dumpster nuts etc... not so much for the 5/8".

Start smaller than I did. My thinking was that my gantry would look the same for a 48" table as it would for a 96" table... why save the 20$ in MDF and $50 in lead screw? I am glad I have the working area, but I am already working on revisions and a smaller table design.

Take the addage that 'no one builds only one table' as fact... Your first hobby cnc is where you learn how to build your second cnc. Select components that you could eventually transfer to version 2.

Good luck on your build!!

-

11-29-2008, 06:50 PM #4

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

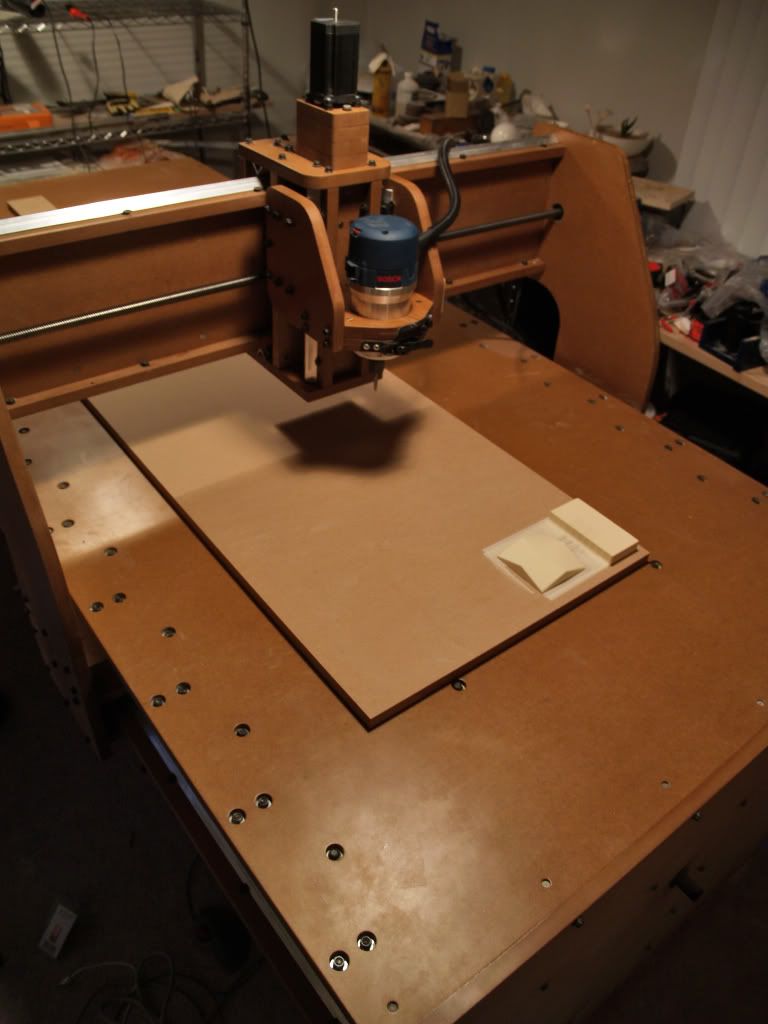

Very nice workmanship on your machine. You spent considerable effort in the finishing of the MDF parts. Is that satin polyurethane with no stain? Clean looking machine design as well. Congrats.

CarveOneCarveOne

http://www.carveonecncwoodcraft.com

-

11-30-2008, 12:55 AM #5

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

-

11-30-2008, 02:13 PM #6

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

-

02-03-2009, 01:08 PM #7

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 166

Awsome machine and I love the renders too, such a nice project overall. If you ever decided to release the plans to the public, please let me know as I would love to have a go at building one of these.

Cheers

Gav

-

12-14-2009, 03:56 AM #8

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 1

-

12-14-2009, 04:15 PM #9

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

Similar Threads

-

Trying to find out more information about a "misterious" CNC used machine -see pics

By jcatanduva in forum Want To Buy...Need help!Replies: 4Last Post: 12-23-2013, 11:52 AM -

X Axis "Goes Off Pattern", "Awry", "Skewed", "Travels"

By DaDaDaddio in forum Laser Engraving / Cutting Machine General TopicsReplies: 1Last Post: 05-06-2013, 09:59 AM -

CNC Router-20"x20"x4" Build or buy machine?

By cbstephenson in forum DIY CNC Router Table MachinesReplies: 3Last Post: 06-04-2010, 08:02 AM -

Solsyva 24" x 48" build, 1st machine

By nikbrewer in forum CNC Wood Router Project LogReplies: 10Last Post: 09-17-2008, 12:27 PM -

17 Years of "Grime" on an Axis card

By donl517 in forum FadalReplies: 8Last Post: 12-28-2007, 12:02 AM

Reply With Quote

Reply With Quote

It's exactly what I did on the two 4'x8' MDF tops of the work tables I recently built for my workshop. Even used the 220 grit sandpaper.

It's exactly what I did on the two 4'x8' MDF tops of the work tables I recently built for my workshop. Even used the 220 grit sandpaper.