could be too much pre-load on those bearings did you run it in after you got it back? does the spindle spin freely by hand?

I had the same problem with mine and checked everything to no avail, untill I remembered that 6 months previous a semi took out 3 transformers a quarter mile from my house and fried all the GFCI's, ans surge protectors in the house as well as my paint shop, so remembering that led me to replace the GFCI in my workshop and all was well

Its amazing how small the path to ground needed to trip these GFCI's i have seen spiderwebs trip them

Thread: a couple cnc questions

Results 561 to 569 of 569

-

07-27-2010, 01:36 AM #561

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 724

-

07-27-2010, 12:15 PM #562

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Yep! FIRST unplug mill and check with highest Ohm setting for any ground fault between smallest plug pin and round ground pin. If mill checks OK, (Absolutely NO continuity reading) I would recommend replacing that GF receptacle. About $20 at Lowes or HD.

http://www.homedepot.com/h_d1/N-5yc1...atalogId=10053

http://www6.homedepot.com/tv/hdtv_pl...videoID=000467

CR.http://crevicereamer.com

Too many PMs. Email me to my name plus At A O L dot com.

-

07-27-2010, 11:28 PM #563

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

Thanks for the great suggestions guys. Today by accident i noticed that there is resistance, so a short, between the terminals. i thought it was in my wiring but nope. i made a video to show you guys what im talking about.

[nomedia="http://www.youtube.com/watch?v=tTMCESOol6s"]YouTube- 802 0336[/nomedia]

- is there something wrong with the motor? or is that normal and i should replace the GFIC's in my garage

cornbinder: i thought something like that might be happening, so i took the motor off the mill.

Cheers

-

07-28-2010, 12:35 AM #564

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

You SHOULD have continuity between the motor winding leads. Try touching one meter probe to one of the motor bolts or frame and one probe to any of the motor leads--You should NOT have any continuity that way. If none, then turn up the K Ohm setting to highest and try again--still should be nothing. Also test the power cord between smallest pin and longest pin. This would cover any short in the mill wiring--should be no continuity there either.

I assume that you tried running it in the OTHER GFIC? I doubt both of them would fail at one time.

Also, a GFIC will normally carry less current than a regular receptacle. If your motor is pulling up near its Amp limits--then that could cause it to trip.

CR.http://crevicereamer.com

Too many PMs. Email me to my name plus At A O L dot com.

-

08-02-2010, 09:41 PM #565

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

Well still no love.

I have tried every receptacle in my garage with no different results.

I have the VFD set to show amps, i can turn on the motor until the vfd shows about 1.8 amps. Then it trips. but it runs happily for a long time at 1.5 amps (the lowest rpm's the motor can spin basically). I re-wired the whole lot and checked every wire. Still the same problem.

No continuity between the 2 plugs that go in the wall, no continuity between frame and wiring leads.

I wish it was just like oof, the motor broke. now i can replace the motor. Its just not worth throwing money at stuff at this point hoping to fix it. I will replace components if i know what needs to be replaced. My mom said she would replace the motor/vfd for me but theres no sense in doing that if my motor/vfd is working and its a human error.

Heres the video

(click on video to start it)

-

08-02-2010, 10:30 PM #566

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Is it your rig or your electrical power? Let's narrow it down. Take the motor to your neighbor's garage and try it with HIS power. If possible, find someone (Or a shop) who has a 20A receptacle and try it there.

CR.http://crevicereamer.com

Too many PMs. Email me to my name plus At A O L dot com.

-

08-03-2010, 12:01 AM #567

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 3063

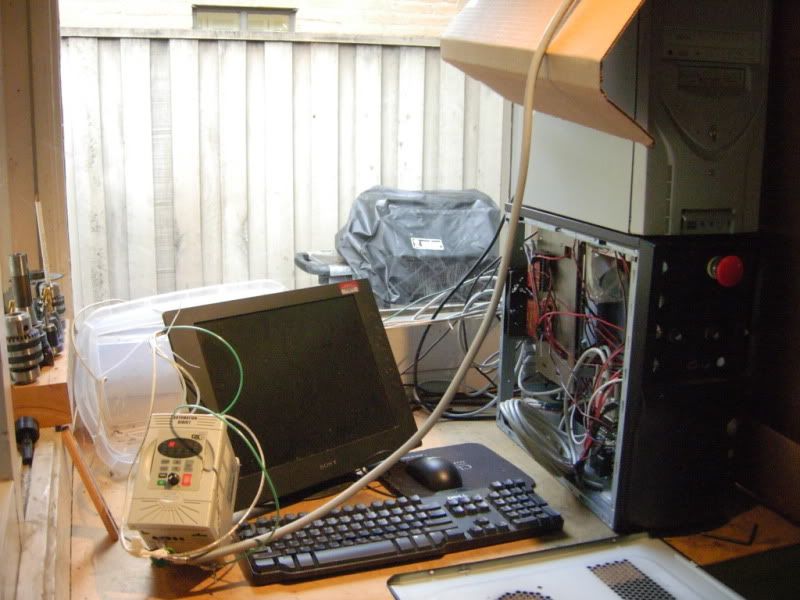

-

01-04-2011, 07:17 AM #568

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

I head back to british Colombia tomorrow and won't be around this hardly at all for a long time. Thinking of getting rid of her

-

01-04-2011, 12:29 PM #569

Teyber12

How much more time are you going to be away from home?

Please, keep us posted on how you are doing.

Jeff...Patience and perseverance have a magical effect before which difficulties disappear and obstacles vanish.

Similar Threads

-

New guy with a couple of questions

By blackhollowmfg in forum Waterjet General TopicsReplies: 5Last Post: 01-31-2007, 07:58 PM -

Couple Questions

By CNCoperator123 in forum DIY CNC Router Table MachinesReplies: 21Last Post: 09-21-2006, 07:21 PM -

saying hello with a couple of questions

By JonC in forum DIY CNC Router Table MachinesReplies: 29Last Post: 06-27-2006, 05:57 PM -

Couple New Guy questions

By Black Mesa in forum Open Source CNC Machine DesignsReplies: 8Last Post: 06-13-2006, 10:40 AM -

A couple of questions about MC

By Tarkus in forum MastercamReplies: 4Last Post: 12-28-2005, 04:59 PM

and im getting this from my biggest customer

and im getting this from my biggest customer

Reply With Quote

Reply With Quote