Results 21 to 40 of 63

-

05-03-2011, 10:35 PM #21

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 230

Mayan Calendar

Regards, Carl

-

05-04-2011, 04:50 PM #22

Registered

Registered

- Join Date

- May 2009

- Posts

- 435

Yep, here is the adobe illustrator file: http://www.vectric.com/forum/download/file.php?id=884

-

05-04-2011, 05:05 PM #23

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 230

Mayan Calendar

Thanks for the file link!

CarlRegards, Carl

-

05-04-2011, 07:22 PM #24

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

Mirror image FIXED!

Mirror image FIXED!

Thnaks to Angie for the tip!

Changed just the X to reverse and all was well!

Here is a new project I cut last night:

(See picture attachments)

-

05-04-2011, 07:32 PM #25

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

In response to Pauls question on the calendar finishing..

The Mayan calendar and the Harley logo were made in MDF and spayed with Rustoleum Copper spraypaint. For the Mayan calendar I took minwax Ebony varnish and coated it let set and wiped the surface to create some definition. I didn't get quite the results I was looking for with that and will go a different route next time but it does look fairly good anyway.

-

05-05-2011, 09:32 PM #26

Someone posted gcode in several sizes for an Aztec calendar. All the info needed to route the calendar bit/doc etc. Doing a search will turn it up.

-

05-09-2011, 06:20 AM #27

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

Arhhh!!

I am loosing steps on the Y axis when cutting long jobs like the Mayan calendar.

I beleive the hex scews (THe big and small ones) that mate the "Y" axis stepper to the rest the drive line under the table is getting loose and slipping under heavier load.

I have torqued down the hex scews and sem to have spripped out the larger of the two which made a bad situation worse.

1. Has anyone had issues with their Y axis slipping unde heavy load on an FLA-100?

2. Anyone know the exact size of both of the hex scews that grab the stepper motor in the aluminum coupler?

I have attached a picture of the latests botched job. You can see the point where it lost the step on the Y axis and started to ruin the rest of the job.

Thanks!!

-

05-12-2011, 05:16 PM #28

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

Lost steps on the Y axis...

I have been working through issues with losing steps on the Y axis and am starting to narrow it down but still unsure as to the root cause.

I have tightened/swaped out/ replaced/ and tested the drive tain components and am confident that lose and or slipping axis components are not the issue at this point. Beond that I am at a loss.

Here is a description of the issue:

1. I pull up the file I want to cut (mayan calendar) with Mach3 and start the job.

2. Everything goes fine for a short while.

3. I check back in 15 minutes and stop the job and send the request to zero the machine to find that it has lost its place in the forward direction on the Y axis a 16th". If I let the program run longer it creeps away further and further in the same direction.

The weird part of this is that When I first started to a month ago it was cutting everything fine and was DEAD ON and I have a few perfect pieces to show for it but now I can't finish a job without ruining it to save my own life.

Stepper going bad?

Steps per inch fell out of wack?

???? Ideas?

:tired:

-

05-12-2011, 06:26 PM #29

Registered

Registered

- Join Date

- May 2009

- Posts

- 435

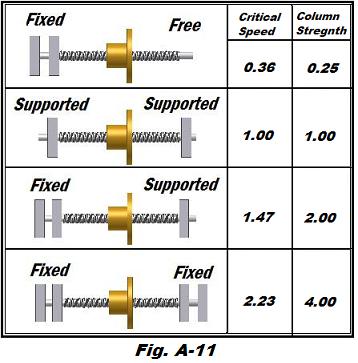

Something to consider might be the end fixity, see this link: Bearing Supports and End Fixity

Also see attached picture.

Can you wiggle the z-axis from side to side? You may be losing a small amount each time it moves back and forth. Putting shaft collars on each side of the bearing block could help it. It would suck having to tear it apart and put 2 extra shaft collars on each axis, but it might be the problem.

You also might want to make an adapter to hold a pen and run a few test programs on paper instead of wasting wood while you set it up.

Maybe someone else can chime in for a 2nd opinion on what it could be.

-

05-13-2011, 04:46 PM #30

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

More work trying to resolve the step issues...

More work trying to resolve the step issues...

Hey CNC Lurcker,

Thnaks for taking the time to put together that information!! Very informative stuff.

I wanted to clear up something that I may have misrepresented: When I said I have a step issue on the "Y" axis I was refering that to the long front to back axis on the table.

Last night I sat down and tested a few different things only to find more questions than answers.

1. I recalibrated the machines "Steps per inch" on all axis. This was very troubling since I could not get a repeatable number on the "Y" axis. It was anywhere between 1.009 and .091 and I reran the calibration 20 times.

2. Checked and recheck all the hardware and found no noticable issues.

3. I did notice that the Geeko G540 was super hot but as I understand it from reading other posts that is just how they run.

4. My steppers are still running +120 degrees at all times.

I can't figure out how I could cut a perfect item such and the Harley Davidson logo not more than a week ago and then I tried to cut the exact same job from the same file on the same machine 5 days later and its complete garbage. I have attached a picture of the Harley logo I cut last night to illustrate the severe degradation in quality.

I am getting the feeling mu problem is in the electronics! I have another G540 but dont want to blow it out testing if there is an issue matching up to the Nema 23 380oz steppers I am using.

I am wondering if I need to dial in the voltages on the pots for each axis or adjust the voltage on the power supply..? Anyone have any good info on that subject please post a link.)

I hope that nothing is totally fried! (But why would it work great then go to Sh*t all of a sudden?

Help

-

05-13-2011, 06:26 PM #31

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 230

Are you sure the setscrews holding the lead screw to the motor are tight?

Regards, Carl

-

05-13-2011, 07:06 PM #32

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

Set screws

Set screws

It was the first thing I checked. (3x times over) I was sure that was the issue. (Then after swaping out some parts tightening everything up and locktightening all the required areas I am convinced that its not "slipage".)

The inablity to get the step to calibrate to 1.00 "seems" to be a clear indicator that I have a stepper/controller/power issue. It could be anything really (I am not qualified to rule out anything) but If I can't even move 1.00" with no load and its producing posative and negative numbers (As high as 1.009 and as low as .091 when trying to move 1.00") on the calibration reading when setting the stepps it seems like my machine has developed scizoferenia or sometihng!

Please help.

(group)

-

05-13-2011, 07:36 PM #33

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 230

At this point, I would disconnect the lead screw and see if the table moves freely. It sounds like something is binding. Reduce it to its most simple terms

(no motor) and if necessary no lead screw. I bet you will find that something has moved out of adjustment. Just trying to help.

CarlRegards, Carl

-

05-13-2011, 07:56 PM #34

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

I will try anything

Thanks for the idea!

I will try anything and I have not ruled out movement issues since its only the Forward momvent on Y axis that is creeping away from zero that would indicate binding too..

Its very frustrating especially since everything was going so good albeit for only a short period of time prior to this issue.

I just want to get back to good and start making stuff again.

-

05-13-2011, 08:31 PM #35

Registered

Registered

- Join Date

- May 2009

- Posts

- 435

That last pic shows the HD logo pretty messed up. Even if it would be off a bit, it shouldn't look like that. What speed are you cutting that at? I cut some MDF at 100 ipm and the edges looked ragged, so I bumped it down to 60 ipm and it looked much better (almost crisp edges).

Also, what acceleration number do you have yours set at? At one time I had it about 220 and posted a screenshot of it and someone pointed out that the number was was to high. I bumped the acceleration down, I don't remember to what exactly, maybe around 40 or something. Not sure if fast jerking would throw you off or not.

-

05-13-2011, 08:42 PM #36

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

Mach3 Settings for the FLA-100 2'x 3'

Mach3 Settings for the FLA-100 2'x 3'

I saw the speed correction that you mentioned and made simalar adjustments prior to all of my troubles creeping up.

My steps per inch are in the 4000 area, acceleration was 220 and I halfed it to 110, and I took the 60 and choped it to 20 and added a delay of -2 (This is all off the top of my head since I am at work at the moment but I think its acurate.)

I was also wondering how much mialage we should expect out of a V-BIT? I bought a CMT 1/4" 60 degree VBIT off Amazon and have put maybe 15 to 20 hours on it at this point. At what point do you consider it out of life? (I know its a total newbie question...)

(chair)

-

05-14-2011, 09:49 PM #37

Registered

Registered

- Join Date

- May 2009

- Posts

- 435

Well, it looks like I have a similar problem, but I didn't have time to diagnose it because I'm at my in-laws place now. I was cutting a plaque for their 50th anniversary this morning and some of the letters were not engraved as deep as the others.

I ran the entire program again and it did the same thing. You'll see that the x and y axis are working correctly because after the 2nd run, everything is in the exact same place, but the z axis is the one floating for me. After awhile, the z starts drifting and moves so high up it didn't even touch the board (see picture). I have the 2010 Mach screenset and used the auto-z after the bit changes, so I know the z axis is good at the start.

-

05-14-2011, 10:04 PM #38

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 116

You will not believe this!!!

You will not believe this!!!

I was messin with the machine last night..

In a flash of simple brilliance it hit me.

ELECTRICAL INTERFERENCE!!!!

I looked under the table and said well "gosh darn" the Red serial cable that goes to the Y axis which was the source of my trouble was sitting firmly underneath the Geeko G540!!

I moved it away from the G540 and cleaned up my cabling a bit (Needs more work) then I ran two Harley sign jobs in a row.

They cut PERFECTLY!!!!!!!!!

My jaw is still on the floor...

So many possibilities when problems creep up... Thank you guys for all your helpful suggestions!!

CNC Lurker: I hope that yours is as simple to fix!! Keep us posted.

(group)

-

05-14-2011, 10:41 PM #39

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 242

CNC Lurker: That problem is the depth of the material compared to the depth you told the machine to go. Send over those lines of text again and tell the machine to engrave deeper.

You'll notice this issue a lot when you try to engrave natural product only .01" deep.

-

05-15-2011, 04:01 AM #40

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 230

Similar Threads

-

2'x3' Free Router Plans - All Aluminum and Steel, Completely Bolt together

By LaserImage in forum Open Source CNC Machine DesignsReplies: 453Last Post: 02-28-2012, 01:28 AM -

Revision 2 of FLA100-00, a full 2'x3' router table plan.

By solodex2151 in forum DIY CNC Router Table MachinesReplies: 5Last Post: 02-27-2009, 06:40 PM -

Metal Max Mill?

By LinearMotionFan in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 12-17-2008, 11:22 PM -

My first Build (2'x3' $1800)

By GlacialWanderer in forum DIY CNC Router Table MachinesReplies: 26Last Post: 12-08-2008, 01:37 PM -

Metal Mill

By coolman in forum Vertical Mill, Lathe Project LogReplies: 0Last Post: 12-24-2004, 06:23 PM

Reply With Quote

Reply With Quote