http://cnc4pc.com/Tech_Docs/C11R8WG.pdf

Its not very clear in my opinion. I would have liked a nice layed out diagram where each terminal is specifically labeled. Isn't even very clear what the dir/sep/com is for each axis. I have only done this once before and that BOB had a wonderful wiring diagram which marked it all out.

Oh yea, and all these things want separate power supplies like for the VFD input. I have 12V from the large coil power supply, and a 12V from the computer power supply. No grounds can be common, or something.

Thread: 18x18 Linear Rail Tormach Build.

Results 241 to 260 of 995

-

01-18-2013, 08:16 PM #241

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

-

01-18-2013, 08:50 PM #242

Gold Member

Gold Member

- Join Date

- Jan 2006

- Posts

- 2985

The isolated output is for the cheap DC drives, where the potentiometer is connected to the AC circuit. I can draw up a quick diagram when I have a chance.

Matt

-

01-18-2013, 09:31 PM #243

Gold Member

Gold Member

- Join Date

- Jan 2006

- Posts

- 2985

The AC connections are straightforward and called out in the VFD manual, including the brake.

I attached a picture showing MINIMUM connections to get the drive to go forward and reverse with an analog speed set from mach. I did not show any E-stop, enable, or anything else. I think you want that!

It sounds like there is an enable (EN) output on your BOB that could be used to enable the VFD but as you said, the documentation you linked to is pretty lame.

The analog connection is simple. I showed on my drawing using the builtin 10V supply from the VFD to power the analog output from the BOB. This may not let you get full 0-10V output from the BOB which may reduce your top speed. You can use a separate power supply (wall wart) to power it with 12 volts. In that case, you would tie together the common for the BOB analog, the VFD analog and the 12v supply. You would connect the 12v positive to the 12v connection on the BOB analog section and would NOT connect the 10V from the VFD to anything.

Make any sense?

Matt

-

01-18-2013, 10:29 PM #244CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

01-18-2013, 11:21 PM #245

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

I was hoping those 2 relays on the board could be used to control liquid, and air.

I am going to have to sit and digest that for a few minutes. In the meantime my CAD program isn't working, so I have to manually figure out the plotting of the Z spindle plate. It is cutting right now.

Remember those extra set of rails I scored on e-bay? They were 2" longer, so I can now have a more stable Z travel, plus the carriages were wider and lower. Overall a nice investment for a random "make an offer" button on ebay. Never thought this guy would let them go for what I offered. They were filthy, but brake cleaner fixes everything.

-

01-19-2013, 04:45 AM #246

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Z axis is starting to take shape. Whoever asked about it a few pages back, will have a much better idea shortly.

-

01-19-2013, 04:51 AM #247

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 279

C11 can be used ot control relays.

It was me. Photos or it ain't happening.......

C11 board can control air or coolant.

Chris

-

01-19-2013, 05:08 AM #248

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 279

pdf

Nateman,

Do you not have a copy of the C11 BOB manual? It spells out exactly how to run a VFD from pin 14.

Here is a link to the manual:

http://cnc4pc.com/Tech_Docs/C11R9_3_USER_MANUAL.pdf

Here is a link on how to wire a VFD:

http://cnc4pc.com/Tech_Docs/4_C11GR8_6.pdf

This guy does an excellent job on explaining the board and one little detail they messed up on:

ThunderDork » DIY CNC Router ? CNC4PC.COM C11 Wiring

-

01-19-2013, 05:46 AM #249

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Its a brand new thing for me, so it takes some breaking out of my comfort zone.

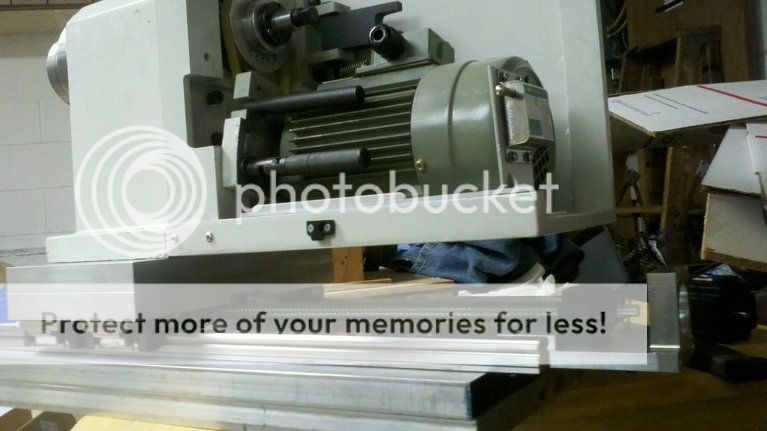

Pics as requested

The spindle EFFORTLESSLY slides up and down on the rails. 200 lbs just like it was nothing. I can't be more pleased... and its not even finished!!

The gantry will start to get constructed now that I have some of the extrudes filled with the concrete. Should be cured enough to work now.

-

01-19-2013, 09:14 PM #250

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 279

Sweet

Looking good Nateman!!

-

01-19-2013, 10:47 PM #251

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Thanks! I made a dxf of the plates that the spindle will sit on. Capable of at leased 20 degrees of left & right - somewhere between 5 & 7 oclock to help in tramming

-

01-20-2013, 04:04 AM #252

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Ok, closer to 5° as my math turns out. 2.5° in either direction.

-

01-20-2013, 11:41 PM #253

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

In the spirit of daily updates...

Here is the lower layer of the Z axis plate:

Through holes to mount to the rails. This set of rails is slightly different then the X & Y rails. Actually the rails are identical, but the bearing blocks are shorter, and wider. perfect for an axis that will have to fight gravity.

Here is the top layer with a 2.5°tilt clockwise:

Here is a 2.5° tilt counter clockwise:

The 6 holes are for the Tormach head assembly to bolt directly to that plate. I have plans to bolt an adjusting mechanism on each side that I can tram the head accordingly.

-

01-21-2013, 06:54 AM #254

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Last update for the night:

The 2 "tramming ears" A threaded hole will go in both sides, to rock the spindle left and right.

Through holes for 1/2 13 bolts. Now off to the store tomorrow to pick up the necessary hardware.

-

01-21-2013, 06:25 PM #255

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 216

Any tips on tightening/preloading the square ballscrew nut? I mean, the actual nut on the end of the ballscrew outside your bearing blocks? I cant seem to think of a way to hold the ballscrew still enough so that I can tighten it.

-

01-21-2013, 07:06 PM #256

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

Vise grips, with something like wood, or some aluminum in the jaws.

If the ball not doesnt go all the way to the bearing block, you can just grip the actual ball screw with vise grips. Will definatly mess up the threads a little bit, but sine there will never be any use to that section, it could get a little marred.

-

01-21-2013, 07:23 PM #257

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 216

The other end of the screw is smooth for a fixed bearing so maybe ill give it the ol' electrical tape - wood - vice grip treatment. Figured their might be a more sophisticated way but I cant see why that wont work. Is there any specific spec you followed for how tight or just tighten until it feels tight? Thanks! Your build is looking great

-

01-21-2013, 08:19 PM #258

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

no sophistication at all. Just tightened until it felt right. Did a "backlash" test with an indicator. As long as it works i guess. I will find out more once i actually start to use the machine. At least I can service everything easily enough.

-

01-21-2013, 08:27 PM #259

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 216

Nothing wrong with keeping it simple! I have the same ballscrews I think. Are you doing anything to preload them? (Oversized balls? Double Nut?) So far I haven't done anything in that regard. Also, what are you doing for ballscrew/ballnut greasing? I'm probably just going to manually grease mine. On the side of the ballnut I noticed a threaded hole that looks like it could be for installing a zerk grease fitting. Does yours have that as well?

Thanks for all the tips and answers

-

01-22-2013, 01:11 PM #260

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

I hardly feel I am in any position to give anyone advise. I have enough ball nuts to double nut all the axis, but they seem perfect without them. If I run into problems I can add them later.

Yes, my 1605 ball screw nut has the same hole for a grease zerk which I will manually grease up everything.

The spindle is now mounted:

I still have to figure out how I want to bolt the two 1" plates together and allow for column "nod" tramming, and tilting side to side for the axis. Have to do the same for the spindle head plate as well.

The 80/20 finally arrived:

You can see the HUGE difference in webbing thickness of the 1545 piece on the bottom vs the 4590 piece above. Its solid as a rock. I debate filling it with concrete because its so much stronger and heavier, but I still worry about vibration so i think I will fill these with a sand/resin mixture.

Similar Threads

-

14x14 Linear Rail Industrial Hobbies Build (Charter Oak Automation)

By nateman_doo in forum Vertical Mill, Lathe Project LogReplies: 146Last Post: 03-06-2023, 08:14 PM -

Open Rail DIY Linear V Rail System

By kram242 in forum News AnnouncementsReplies: 0Last Post: 06-11-2012, 03:33 PM -

Linear Bearing vs Linear Rail

By microdot in forum Mechanical Calculations/Engineering DesignReplies: 2Last Post: 10-27-2009, 04:54 PM -

PBC Linear Offers New Profile Rail Linear Guides

By Pacific Bearing in forum News AnnouncementsReplies: 0Last Post: 04-30-2009, 09:53 PM -

6'x10' cnc build, what linear rail setup to use

By davy182 in forum Linear and Rotary MotionReplies: 2Last Post: 04-06-2009, 11:51 PM

Reply With Quote

Reply With Quote