That is some neat stuff man but you do realize that the wizards in Mach3 already do most of that and then some right..... Or maybe you are using emc or something.... peace...

Thread: a couple cnc questions

Results 361 to 380 of 569

-

03-29-2009, 11:11 PM #361

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Teyber....

-

04-05-2009, 10:51 PM #362

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

thanks! and i kind of forgot that :P i am using mach3 so haha fail.

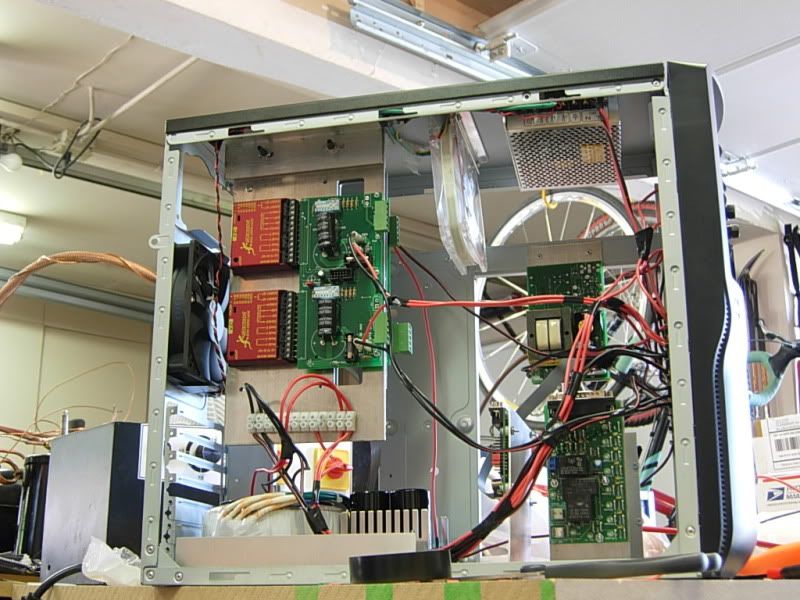

I re-did a lot of the wiring to make it less cluter-ly and to actually solder all the connections/heatshrink et cetera and have a lot less stray wires. I still need to wire in all the grounds which brings me to a coulple questions.

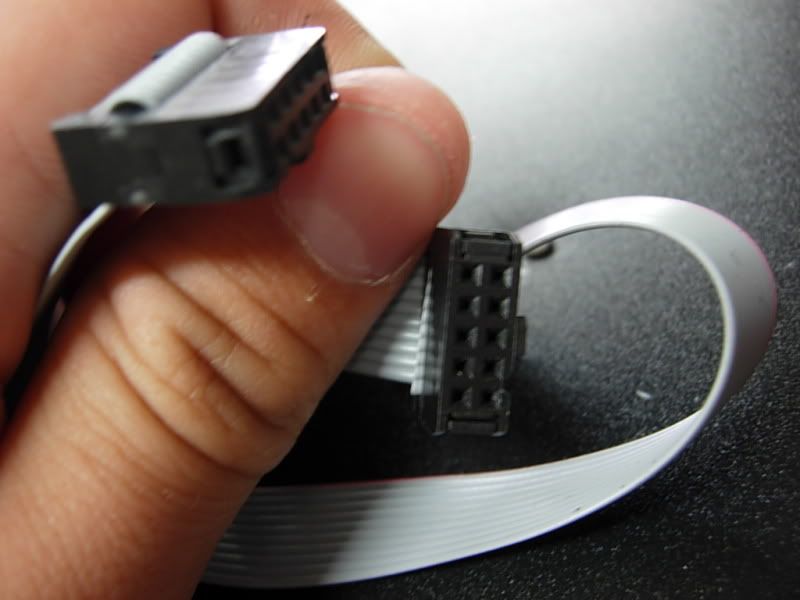

Anybody know what connector i would need to attach these? would i just need a parallel male to female adapter?

anybody know what this cable is called?

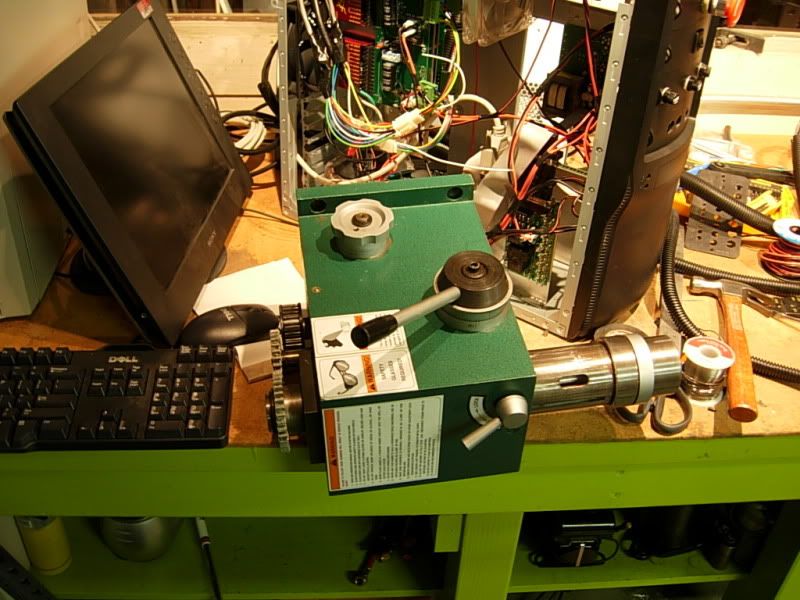

Finally, i did something really dumb. i was working very late in the night (read- after 2 am) when i should have been sleeping and just had a brain fart. now with that said whats the best way to recover from this:

should i dremel off part of the screw, take out the z axis gib and the z gib screw thing and order a new z axis gib and a new screw from grizzly?

Thanks!

-

04-05-2009, 11:07 PM #363

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

OOHh man that sucks .....

I think I would be inclined to take another piece of steel and stick it into the little slot that the adjusting screw rode in and tap it with a hammer until it came all the way out and then try to remove and repair the screw. There are a few guys on here that have had problems with engagement and slop in these adjustment screw/slots and have welded a lump of metal onto the head and then put it in the lathe and trued up the weld to fit the slot exactly so you might be able to fix it that way.... Good luck man....peace

-

04-05-2009, 11:30 PM #364

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Pull the Gib, then remove screw and clean them both up with a file. MOST of the gib should still be smooth enough after that. I guess you know that the screw head is supposed to be in those grooves at top of gib.

If Gib won't remove, you will have to lift head enough off of dovetail to release it. Then screw will come out.

CR.

-

04-05-2009, 11:36 PM #365

-

04-06-2009, 01:28 AM #366

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

pete- the problem is with me though not the mill. you need to take the screw out, put the gib in, then put the screw in...

i was very tired and oof

i was very tired and oof

cr- ive tried but i can't get the gib out which makes me think i need to dremel it out. ill give it some more tries though.

which makes me think i need to dremel it out. ill give it some more tries though.

al- long story, but the ubob assumes your connecting something very far away so they included a 5' cable that i need, and what im connecting is about 4" away, i just need a simple connecter i just want to make sure its a simple male/female connector or something.

Cheers!

-

04-06-2009, 01:46 AM #367

Still not clear what you are trying to terminate there?

If your caption refers to the 25pin D, you can get 25pin Gender Changers to switch male to female.

If it is the ribbon cable that you need to shorten from 5' to 4" you can cut the ribbon with scissors and press another end on, gently in a vise.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

04-06-2009, 02:58 AM #368

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

That Gib is NOT going to come out until you raise the head clear of the dovetail. Get some help, raise the head almost OFF and put a block of wood under it. Now wiggle the Gib and it will come out. If you can't MOVE the head, Get some help and unbolt the head from the slide. THEN you can generously lube the dovetail and (protecting with a block of wood) beat the slide up (or DOWN--might have to remove column) and off.

Tell Tom what you need, and he will make you a different cable.

CR.

-

04-08-2009, 01:38 AM #369

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

al- ill snap a pic for ya when i get back in cali. There is a connector that goes from one of the ubob cards to the ubob, however the included cable does not attatch(as shown). i think you need a male/female parallel port with male connecters on both ends or something.

cr- ill try again but i havn't had good luck with candcnc. I feel like im bugging because ive started 2 topics in the yahoo groups, left a message on his phone, emailed him 3 times then he emailed me twice saying he would make the cable then never responded to me. My candcnc order was $275 i was hoping i would get a little more support.

Speaking of support, i emailed grizzly to see get a quote on a new z axis gib and screw, they responded to me twice in 1 day and they are sending me new ones for $8 or something. the 2 parts that the screw slips into the gib were pretty mashed and kind of lost its edge, i imagine it can't be great for the performance and for $8 might as well get new ones.

-

04-15-2009, 12:03 AM #370

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

sweet- all my problems are solved

productive week and i didn't even touch anything lol

productive week and i didn't even touch anything lol

1) i got through to ca dn cnc- hes a very nice guy and is sending me the longer 10 pin idc cables.

2) i got the connector i needed for the parallel cable its hooked up and fits.

its hooked up and fits.

3) i got the z axis gib and gib screw which i thought i was screwed on

4) i got cad/cam software.

Once its all here its just a matter of assembling it then i can start fine tuning!

-

04-15-2009, 03:33 PM #371

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

That's great! Maybe in another month or so you can start making copper chips again.

CR.

-

04-16-2009, 05:31 AM #372

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

thanks mate! im getting closer every day

you know this x3 so well cr its amazing. i ended up taking everything apart (column from mill, head from column thingy) and hammered it AWAY from the side with the gib sticking out and it came off

you know this x3 so well cr its amazing. i ended up taking everything apart (column from mill, head from column thingy) and hammered it AWAY from the side with the gib sticking out and it came off  sweet.

sweet.

However two things backfired: im sure i will need to tram my mill now

and

the gibb is NOT the same gib

pictures to show my frustration of being so close yet so far LOL. all torn apart

reminds me of my noob java programing without netbeans or sth. you know you forget a brace or something, have 10 errors or so but when you fix the brace you have 20 errors because the compiler wasn't even reaching the next method. It seems like your moving in the wrong direction when your actually moving in the right direction.

I will be contacting grizzly to pray i can get the gibb i need the one i have is pretty trashed

the one i have is pretty trashed

edit: note on MY gib it has the 2 slots ground into it for the gib adjustment

-

04-16-2009, 01:59 PM #373

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Bummer!

Make sure you order the right part number:

Gib: P0463064

Screw: P0463063

http://www.grizzly.com/images/partslists/g0463_pl.pdf

CR.

-

04-18-2009, 05:06 AM #374

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

WAHOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

Im SO happy! im so easily amused haha.

1) i turned on the controller and no black smoke!

2) Table is moving!!!!!!!!!! and z axis moves also!!!!!!!!! (but not connected to z axis)

So happy x is making a big grinding noise but im 99% sure its because the motor is not perpendicular to the ballscrew, and also the z axis movies when i jog the x/y axis (i forgot which one i was so excited lol)

x is making a big grinding noise but im 99% sure its because the motor is not perpendicular to the ballscrew, and also the z axis movies when i jog the x/y axis (i forgot which one i was so excited lol)

SO ill try to tighten up y gib and loosen up the x gib and maybe start trying to tune the x/y axis motors

also i think i got the z axis gib "good nuff" for now. Does it matter if it has a dull edge? which is the part that needs to be "perfect", is it the flat side?

Cheers! and thank you all SO much for your help!!!

edit: ill try to take a camera video later

-

04-18-2009, 05:18 AM #375

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Congrats tyber.....

I hope to be there soon. I started on my electronics enclosure today and I am getting ready to install the boards and start wiring it up. I was looking at your Z gib pics, could you not just modify the one you got to work, it seems like there has got to be a spot on the taper that matches up with the one you damaged. Unless the whole thing is thicker or much thinner than yours you might be able to measure the thing, cut off the parts that do not fit and test it for the machine slot and then just cut the small slit for the adjustment screw with a file or die grinder/dremel to get it to fit nice. That is great again that you did not have any permanent damage. I almost did a boo boo like that yesterday while I was working on the machine. I stuck the gib in the slot and was playing with the ballscrew, manually turned the screw a few turns to see if there was any binding on my reinstall of the screw and managed to push the gib into the Y slide real tight. when I tried to reverse the motion it still remained tight but luckily I was able to travel it enough to loosen it and remove it. Note to self do not do this on the z because it will not be so easy with the weight on it.... Peace...

-

04-18-2009, 05:22 AM #376

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey pete!

I filed the top slit so that the screw just fits in there. Ill take pictures of the post- grinding. TBH i think its gunna work- but im a noob so i don't know where the "contact" or important point is of the gib. Thanks for the nice words i am just thrilled i didn't muck anything up so far electronics wise

the issue with doing what you said is, this is my only machine and so i can't really slot it without a damn z axis gibb bad example but id be like driving a car with a missing engine to buy a engine for it

bad example but id be like driving a car with a missing engine to buy a engine for it

-

04-18-2009, 05:36 AM #377

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Maybe I was not clear.....

What I am saying is that if you take the old one and the new one and put them side by side and there is a position on the pair that they are the same profile and thickness, you can just mark the new one against the old one and cut it off there. Then you can transfer the slot for the adjustment screw to the new part and mark it then cut it with a dremel with a cutoff wheel carefully and slowly or use a small file to make the slot. Or is it totally a different part.. I think that the tapers must be the same or near and the important part is the face and the height so that it fits snugly into the slot. Hard to describe this really.....peace

-

04-18-2009, 06:22 AM #378

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

Ah gotcha. its the exact same size dimension et cetera only difference is size and where the 2 grooves are.

cheers!

-

04-18-2009, 06:58 AM #379

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

well im off to bed

but: axis were moving 6/10 ipm lol remembered jogging only goes x percent of your total speed. didn't feel like figuring out how to change what speed to jog at so i wrote a 9 line program and kept playing with the different axis. still a lot to learn with g-code but i think i can answer most of my g-code questions by trial and error. (for instance if you tell the machine x1 does it move x +1 inch or go to the coordinate 1, et cetera. things that will be easy to figure out once my machine is calibrated). I set the IPM for 120 or so for both the x and the y axis and the acceleration at 20 whatevers (forgot the units).

I had the table moving at 40ipm and was pleased, but ended up at 120ipm (wow it moves) just for fun. have so much mach work to do its not funny. hey theres a weekend ahead

Second thing is i realized my messed up gib will work i looked in the column and on the head, its hard to explain but there is no contact point on my roughed up edge. hard to explain but im 99% sure its good

i looked in the column and on the head, its hard to explain but there is no contact point on my roughed up edge. hard to explain but im 99% sure its good

still gotta figure out why the z is moving with the y axis.

Hopefully it will be looking a lot more complete by sunday.

cheers!

p.s. sorry for my boring giddy rants im just excited

edit: another note... seems the x axis motor is very hot- the point where you jump off and say ow which is 60+c. ill get a thermocouple on it tomorrow. Its fine under 90c correct?

and the aluminum plate the 203v's are on are cool to the touch

-

04-18-2009, 04:16 PM #380

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Haha, it's great to see more people having as much fun as myself with this stuff; I was on here at 2AM last night wondering WHY I was still here reading about metalwork... like 40+ hours during the week isn't enough. Ah well, I love my job.

Anyway, the answer to your question about g-code, (Does x1. move +1 inch or to the coordinate 1.0") is, Both! If you're moving around after a G90, you're in Absolute positioning, and you'll move to the X1.0" from your work coordinate zero.

If you've used G91, Incremental positioning, your machine will move another 1.0" from wherever it is now.

Almost everything I've ever written has used Absolute, unless it was some simple thing in MDI, like positioning for some jog-handle manual drilling.

Have fun, and keep posting progress, your posts are fun to read!

Similar Threads

-

New guy with a couple of questions

By blackhollowmfg in forum Waterjet General TopicsReplies: 5Last Post: 01-31-2007, 07:58 PM -

Couple Questions

By CNCoperator123 in forum DIY CNC Router Table MachinesReplies: 21Last Post: 09-21-2006, 07:21 PM -

saying hello with a couple of questions

By JonC in forum DIY CNC Router Table MachinesReplies: 29Last Post: 06-27-2006, 05:57 PM -

Couple New Guy questions

By Black Mesa in forum Open Source CNC Machine DesignsReplies: 8Last Post: 06-13-2006, 10:40 AM -

A couple of questions about MC

By Tarkus in forum MastercamReplies: 4Last Post: 12-28-2005, 04:59 PM

Reply With Quote

Reply With Quote