Edit: Mis read posts.

Results 401 to 420 of 438

-

01-15-2015, 01:51 PM #401

Junior Member

Junior Member

- Join Date

- Dec 2007

- Posts

- 578

Re: My First CNC, own design, buidling in progress

-

01-16-2015, 11:30 AM #402

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Re: My First CNC, own design, buidling in progress

Well. to be honest.. i have not looked at any option.. why?.. because what i got did what i expected it to do, and even more..

with Kflops and stuf.. it looks to me that you have to really shop around.. Kflop here.. Motioncontroller there.. Userinterface..Customizable?.. Why?.. because it is no good to start with?.. like Mach? ?.. USB 2.0?.. instead of Ethernet?.. nah.. dunno mate.. nevermind..

it all just doesn't look like a one shop solution to me.. EdingCNC provides hardware in the shape of the CPU Board, No further breakout boards needed.. just hook up steppers, or servo's with step/Dir, or.. since recently.. Steppers with encoders..

Ok.. i went on the internet ... and i found this..

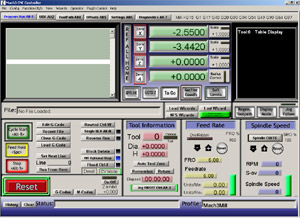

makes me cringe.. makes me want to run, makes me want to shout... makes me about everything except operate a CNC machine with it.. What a Crap interface.. indeed..this calls for a customizable one.. but.. since most people don't have any clue on how to design a user interface.. just let us leave it at that...

-

01-16-2015, 01:28 PM #403

Junior Member

Junior Member

- Join Date

- Dec 2007

- Posts

- 578

Re: My First CNC, own design, buidling in progress

Edit: Mis read posts.

-

01-19-2015, 04:47 PM #404

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 1189

Re: My First CNC, own design, buidling in progress

Hi I like your Post .. you described why i dont use mach at all .. I refurbish ed an Bridgeport 412 to linuxcnc and now i train the Old Master your view on ui is right .. He wants all glove able ...

-

01-19-2015, 05:18 PM #405

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: My First CNC, own design, buidling in progress

http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

01-20-2015, 02:14 AM #406

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Re: My First CNC, own design, buidling in progress

Hoss,

in no way i intended to offend you.. or.. well.. maybe i did..erhm.. how do i put this nicely.. it is all because of my background.. i'm a professional machinist.. a Toolmaker even.. and i've only worked with professional CNC equipement.

I don't know Hoss, if you are familiar with professional CNC equipment?

All of these machines had one thing in common.. NO MOUSE.. and honestly, i don't see how you operate this screen without a mouse..

In my view, a mouse on a CNC machine is a NO-GO..

If i look at your screen.. What a load of info, buttons and windows.. What is it all for?.. on a professional CNC, you don't have all that.. there's a tooltable, that states, which tool is where.. how long it is. what diameter it is.. how many flutes it has, and how long it has been in the machine.. for tool measurements, we just ran a program.. , for setting datums?.. we'use a touchprobe, which would automatically store probe points so one could set datums on each axis..

Maybe i'm overlooking things.. i don't yet have a toolchanger.. i'm planning on building one... and looking at the background picture of your screen.. you have done an outstanding job on that..

But... what keeps puzzling me.. what do all those things on that screen do?.. i mean.. on the Bridgeport CNC i used to operate. changing a tool manually meant, MDI : type in "M6 T2"for tool 2, Hit Enter, Hit Start

It might have worked for you.. but i get the feeling you made a lot more than you really needed..if i build my ATC.. i will program my MacroFile so that when i key in "M6 T2" the current tool (if not 2) is put in the right spot in the tool Umbrella, and it is rotated to tool2, after which tool 2 is picked up by the spindle.

Length measurement?.. well.. i have a User Menu in EdingCNC, and i can pick a Function key to which i want to assign Tool measurement.. I have a toolsetter mounted on a fixed position.. when tool measurement is to be executed.. i hit the right button.. a dialog pops up, asking the approximate length, and radius, and, in case of for instance a ball nose.. a length offset for diameter measurement...

It's just that i have seen a lot of Mach screensets.. and i've never seen anyone even distantly resembling a professional user interface.. only cluttered screens with a lot of buttons, wooden backgrounds, or discolights, metal sheet with rivets, pictures that attract the attention..

In my view, a user interface has to be clean, with as little buttons as possible to operate everything that is needed.. nothing less, and certainly not MORE...

at the moment.. in EdingCNC in Lathe Mode, one can still apply X-offset.. that has to GO.. you don't need X-Offset on a lathe.. you just DON'T.. if you offset X, your whole tooltable is down the F**ing drain.. so i'd rather see that disabled.. you just don't ever apply X-offsets..

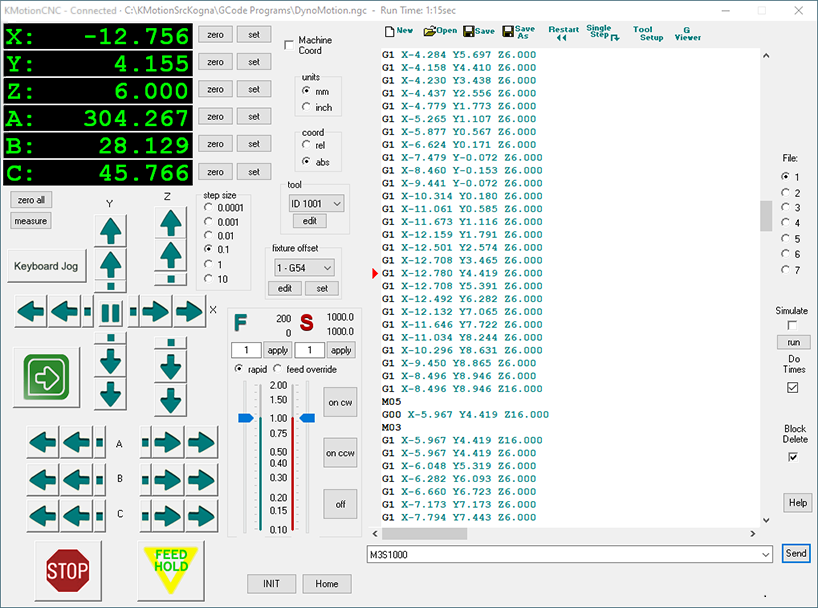

Let me show you where i got my inspiration when designing the User interface of EdingCNC, because i am the guy that designed it, in close cooperation with Bert Eding, the author of the software..

There's a load of buttons under the screen, and some buttons on the right.. these buttons have a function, displayed by the icon next to it on the screen..

That means, on this particular screenshot.. the bottom left button activates an M function, the second an S function, then F-Feed, Touch probe, Datum Set and so on.. on the right.. Tool Table.. , the buttons on the right activate some spindle related functions..

In EdingCNC,we didn't have a fancy keyboard.. so we made use of the F-keys.. they sit on the top row of any keyboard.. and there's 12 of em.. nice.. so F1,is RESET.. always.. F12 is Return to Main menu.. always.. in Main.. F2 =Home, F3= Datumset, F4 program run.. and so on.. F11 enters a User menu, F2-F11 are accessing corresponding User-Subs in the macro file, that one can program how he/she desires... F2 for instance is standard Tool measurement.. i wrote that cycle for Bert, since i was the first User of EdingCNC to use a fixed toolsetter for length measurements.. i'd only have to Touch off Z once.. after measuring my tool... after a toolchange, my machine automatically measures the tool lenght, so no need to touch off..

on the lathe, i made Cycle for Facing (F2) Turning (F3), Filleting (F4) Chamfering (F5), Tool Change (F8) Calibrate X (F9) Calibrate Z (F10) and Part-Program (F11)

With Part program,i can store separate operations to make a complete program.. i make the first part step by step, store each step, and then load the part-program and execute it as one complete program with all previously stored operations.. this gives me the opportunity to program at the machine..

I don't have a mouse on the lathe.. i do have a touchpad on the CNC mill, but that's more for "****s and Giggles.. i hardly use it.. because i'm faster with the keyboard when selecting a folder or a filename... i'm still handy with Tab, and Shift-Tab when navigating through the folders.. (like we used to do in good old DOS)

I was lucky.. when i was building my enclosure.. someone offered me a Heidenhain Console keyboard.. i hooked it up to a Pokeys device, and reprogrammed it.. the "L" Key now inserts G01 into my programs, ToolCall inserts M6 T.. PGM MGT opens the file folder, i can Toggle Single block with the singleblock key,

the Softkey-approach to operating a CNC is in my view the only right way.. and i just don't understand any other solution...

The guys that made Mach.. they are probably good programmers.. but.. they just don't know anything about designing a good User interface..

-

01-20-2015, 02:36 AM #407

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: My First CNC, own design, buidling in progress

Yes I too was a professional machinist, a tool & die maker, R&D Prototype Machinist, Machine shop foreman. The screens you are making fun of are for hobby machines which are for the most part windows based. They appear cluttered but these are for machines that are mouse driven and buttons need to be onscreen because they don't use consoles with physical buttons like professional equipment. People can certainly build consoles with buttons and make their own screen less cluttered as I have with later versions. There are many many kinds out there but to single some out for ridicule that don't suit you just shows your ignorance. My screen you picked on was my first screen made actually and it was just a single screen to combine all the features I wanted for setting up the mill with the atc. You don't need to understand the functions because like I said they were for me and it worked exactly the way I wanted at the time. Good luck with yours and keep up the great work on your projects, I enjoy them very much. BTW, Mach 4 I'm using now is much less cluttered.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

01-20-2015, 02:50 AM #408

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Re: My First CNC, own design, buidling in progress

Hoss, you've got a point with having No console.. but!.. the lathe i'm running.. also doesn't have a Console.. just a keyboard... no need for a mouse with EdingCNC, because everything is accessible with Fkeys..

EdingCNC is after all also Windows Based..

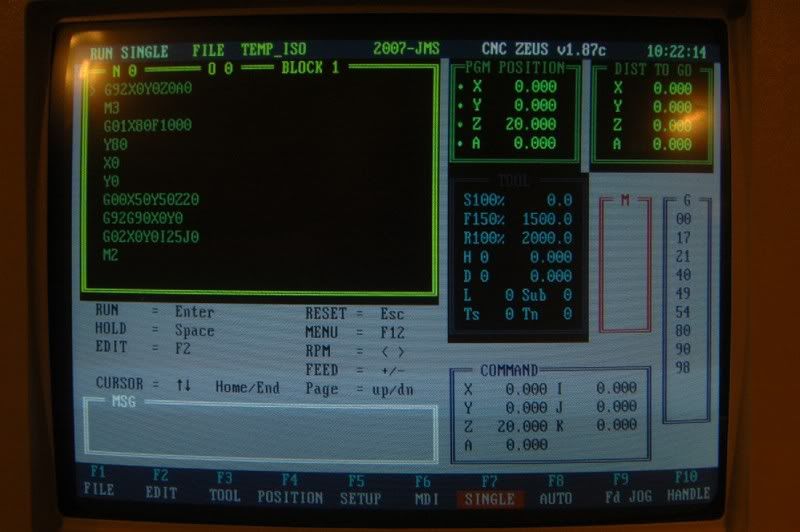

That's why i liked Zeus so much.. no mouse in DOS.. (ZeusCNC ran in DOS), everything was done with Fkeys.. great!.. just like the machines i used at work, and i was used to..

As far as hobby machines go.. why can't a hobbyist machinist not have access to professional User interfaces?.. i mean.. why shouldn't you make a pro-Userinterface also for Hobbyist machinists?.. that.. that was my aim when designing Eding CNC..

What is your opinion on that interface?.. i think you'll agree that it looks far less cluttered compared to Mach..

I found the Fagor Lathe Control and the Heidenhain Mill Control far easier to operate than Mach.. i looked at it briefly, and i was intimidated by the sheer number of buttons on the screen.. and i'm a Professional!.. for Christs sake.. if I am intimidated by that much buttons.. what should a hobbyist feel like?.. it's mindboggling to me..

One day.. long ago.. i was running my conventional lathe.. and my mother walked in to the shed.. to call me for dinner.. i was just finishing a part.. running the machine on auto-feed, and my mother said.. gee.. what a difficult machine must that be.. look at all the handles and wheels.. , and i said.. mommy dearest.. your sowing machine has more buttons, levers, wheels and knobs than this machine.. and you seem to have no problem running that device.. so how can this be difficult?..

To me.. Mach looks like a CNC with sowing machine operation..

-

01-20-2015, 03:21 AM #409

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 599

Re: My First CNC, own design, buidling in progress

Yup your right, to many buttons in mach, and then yes people will say "but you can change it if you want to, make it as little or as much as you want!" All true but there should be a good basic design, which there really isnt. And i got that same line from the camsoft salesman, so it really irritates me. Ill have to get in touch with Bert some time to see if it would be capable of running a cnc punch.

-

01-20-2015, 03:23 AM #410

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: My First CNC, own design, buidling in progress

So you can understand your mother not having any problem running her sewing machine with so many buttons etc but it escapes you that many people have just as little trouble using mach's screens with it's buttons? c'mon. To each his own. Also fyi, mach 3 uses keyboard shortcuts too if you don't like mice. I wasn't aware you designed eding cnc but that makes your bashing of mach 3 understandable if that's the case.

I actually installed the eding cnc demo and liked what I saw, not enough to abandon everything I already have working exactly like I like though. Good luck.

I actually installed the eding cnc demo and liked what I saw, not enough to abandon everything I already have working exactly like I like though. Good luck.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

01-20-2015, 03:35 AM #411

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 1041

Re: My First CNC, own design, buidling in progress

I think maybe you are missing the point with mach and these other pc interfaces. You come from a machining background in a professional environment and I do as well so that's a moot point in the opinions I'm going to express. You don't like a keyboard and mouse with all the user buttons on the screen? They surprisingly have the same functionality as your setup without the need to make a complex panel to do the same thing. On industrial machines I can see the need for the panels but see no need on a hobby machine. Most users have no interest in electronics on the scale you have implemented for your setup. Your machine is very nice but still falls well within the hobby range. You have completely missed the market these interfaces are sold to. You have also missed the fact that 99 percent of the people using them are not afraid of computers and don't have the desire to build a complex panel to do what is done with there mouse and keyboard. I wonder if your opinions will stifle the market for eding by limiting its function when not using a large panel interface that serves no purpose in the hobby domain. As for your opinions of k-flop you are way off base. It can be used as a step direction interface just like eding but is not limited to this. It can control analog servos, brush and brushless and step motors. It can also do closed loop steppers and double closed loop setups with encoders and glass scales. It has a much broader use in a truly industrial environment then what you have put forth by far. It is not for everyone and no one is pretending it does. I applaud your efforts and for years have enjoyed reading your posts. I do not think insulting other people's efforts and hard work is a good way to push your point of view.

Ben

-

01-20-2015, 04:57 AM #412

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 599

Re: My First CNC, own design, buidling in progress

I think you both missed where he stated he helped desing the UI of eding cnc, he does not actually run the company. But whatev. As far as mach3 being a hobby program, you're right however it is being used by quite a few machine manufacturers out there and is being presented as a proffesional cnc retrofit choice, out of the box however the UI does suck (in my opinion, and im guessing others as well or threre would not be as many other choices availabe). Your right about k-flop it has quite the abillities.

-

01-20-2015, 05:02 AM #413

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 1041

Re: My First CNC, own design, buidling in progress

I realize he does not run the company. I was suggesting his idea of a perfect control may not be in line with there markets needs.

Ben

-

01-20-2015, 05:09 AM #414

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: My First CNC, own design, buidling in progress

Yes I was aware he helped design it, note the wink, he mentioned it several times. I second bhurts comment, "I do not think insulting other people's efforts and hard work is a good way to push your point of view." I think you miss the point that if you don't like mach's gui, you are free to use others that are generously made available or free to make you own to suit your needs exactly like you want.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

01-20-2015, 06:26 AM #415

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Re: My First CNC, own design, buidling in progress

For a mere $150 for Mach3 which will run on whatever half decent spare hardware hobbyists have lying around, it fits the niche perfectly.

I can't imagine many hobbyists, which is main the target segment for mach3, would give a toss about having to build a controller chassis and wire up numerous buttons, to simply emulate or control functions the software already provides in a somewhat cluttered but reasonably easy to use interface.

At the very least, try and tell users how they'll create, and move their design and gcode files around using just a control panel, and no mouse, seeing as most are also using their control PC as their design machine as well!

The fact that so many people are quite happy to use it, including many businesses relying on it commercially, is testament to the fact that it obviously fills a gap in a market that nothing else is providing for them.

By the way, I use NC Studio myself mainly, but on my other machines I had no issues whatsoever with using Mach3. I'm not averse to good tools or equipment, but a $25 PC is a far cheaper and more appropriate solution to me than a custom built control panel for hobby use.

Horses for courses.

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

01-20-2015, 12:01 PM #416

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Re: My First CNC, own design, buidling in progress

a CNC Punch... Hmm.. that could be interesting.. a punch should not move when punching.. if you are punching out contours..like nibbling.. i think that asks for some special code.. on the other hand.. i'm dreaming up a hybrid now.. imagine.. having a "Toolchanger" on it, with a Milling spindle with a bottom-die under it, with just a bit larger than the endmill, and a press-plate around the endmill on the spindle, to hold the sheetmetal down.. ,and a punching unit.. you can punch out holes with the punch, and mill contours.that would not be too hard to build?..

Bert Might be interested in the idea.. however he's busy working on all kinds of things.. i already discussed the possibilities of building a Wire EDM machine...

-

01-20-2015, 08:36 PM #417

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

Re: My First CNC, own design, buidling in progress

Your points about good user interfaces are important however just because you are use to something doesn't make it ideal. Especially when a wide array of users are involved.

Consider for a minute the environment I work in, where CNC controllers and similar motion controllers are used in a mass production environment. With each and every controller having it's own interface even simple things like remembering how to save an edited file becomes a problem. This can even change between revisions of the same controller from the same manufacture. A windows based interface can help here as it eliminates the need to reboot your mind everytime you walk up to a new controller.

Now does that mean every Windows interface is a shining example of a good GUI interface to a CNC machine. Probably not but like you people get use to a certain interface as it fits their needs well.

It appears that what you have accomplished is to build an emulation of an industrial machine which has its merits but honestly it doesn't strike me as the way to move forward with the technology. Would somebody coming from a Siemens, FANUC or other background find your controller all that accessible?

Which sounds a bit like the old man that insists that his scratched up vynl sounds better than a CD. I don't mean to sound combative here but you do sound like a paper tape kinda guy, after all it worked in the past why not continue to use it.That's why i liked Zeus so much.. no mouse in DOS.. (ZeusCNC ran in DOS), everything was done with Fkeys.. great!.. just like the machines i used at work, and i was used to..

What bothers me here is that your seem to forget that you can do a custom interface for LINUXCNC, Mach 3 and a number of other PC based CNC systems. As such you should recognize that those that have done so, created an interface that suited them. You really can't knock them for doing so.

As far as hobby machines go.. why can't a hobbyist machinist not have access to professional User interfaces?.. i mean.. why shouldn't you make a pro-Userinterface also for Hobbyist machinists?.. that.. that was my aim when designing Eding CNC..

If you are asking me personally I find cluttered interfaces to be terrible. There are some machines at work where the screens look like alphabet soup. A well engineered windowing interface would go a long ways to fixing them up. The problem for many machine tool companies though is simply not having the talent to do such interfaces.

What is your opinion on that interface?.. i think you'll agree that it looks far less cluttered compared to Mach..

It shouldn't be mind boggling as it is what you are use to.I found the Fagor Lathe Control and the Heidenhain Mill Control far easier to operate than Mach.. i looked at it briefly, and i was intimidated by the sheer number of buttons on the screen.. and i'm a Professional!.. for Christs sake.. if I am intimidated by that much buttons.. what should a hobbyist feel like?.. it's mindboggling to me..

Interesting that you should bring this up because it highlights that a complex interface can be accessible given the time to become one with that interface. It also highlights something else that might not be obvious, machines running Mach and other PC based CNC systems aren't always used in the same manner as industrial controllers. That is they are often used to interactively control the machine which for many of the industrial examples out there is not all that easy to do.One day.. long ago.. i was running my conventional lathe.. and my mother walked in to the shed.. to call me for dinner.. i was just finishing a part.. running the machine on auto-feed, and my mother said.. gee.. what a difficult machine must that be.. look at all the handles and wheels.. , and i said.. mommy dearest.. your sowing machine has more buttons, levers, wheels and knobs than this machine.. and you seem to have no problem running that device.. so how can this be difficult?..

To me.. Mach looks like a CNC with sowing machine operation..

So all of that being said I don't disagree with you 100%. After years of experience with machine tools and automation I honestly believe that many controls designers have gone off the deep end with their touch screen / mouse only interfaces. Such interfaces can be a huge problem usability wise. A common failure with such interfaces is the need to keep track of a mouse pointer or touchscreen button while trying to jog a machine. Implementing hard buttons (left & right, up & down) with tactictile feedback really does make for a more user friendly machine. Sometimes you need to keep an eye on what the machine is doing not the user interface.

The problem with all of that is that there is additional programming involved and hardware fabrication needed. As others have pointed out not everyone is up to that sort of construction. Further a digital panel allows one complete freedom to add or subtract from the user interface. That flexibility has its own advantages.

In a nut shell yes there are a lot of bad user interfaces out there, many on commercial machines by the way. If you don't have a plan to make something better then why bother dissing the interfaces that do exist? You see if your post was presented in such a way that people where to believe that you had a plan to improve things for Mach 3/4 users you might have gotten more favorable responses. Instead you put Mach and a bunch of other systems into a negative light yet hold up what is a throw back to decades old systems as an example of how we should move forward. You have to see how many would see your approach as a step backwards not forwards.

-

01-21-2015, 12:30 AM #418

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Re: My First CNC, own design, buidling in progress

I am well aware of a lot of things, let me explain..

I got very little training regarding CNC, in fact.. the first CNC i learnt to operate i taught myself.. one of my colleagues left the manual lying around.. i had work for that lathe (Chevalier FLC 1840 with Fagor 800) and the two colleagues that were trained, left the machine standing as it was, because they found they had better things to do... manual milling for instance.. "Hello Dumbass".. Fire up the CNC, and do the milling in the mean time.. that's what CNC is for after all..

Anyway.. i had to work late to get my parts finished.. i picked up the manual, and within reading 5 pages i was already past starting and referencing, straight on to calibrating the tools and setting the offsets.. so i went one page further.. Operations.. Riiiight.. ok... so that's how it works.. that's not hard at all.. let us key in some numbers.. and let the lathe do the crunching.. 1 hour later.. i had my first part finished.. and i knew the basics of operating this lathe..

Am i therefore a genius?.. off course.. i'd like to think so.. but .. no.. i'm not really dumb either.. but the CNC Controller.. the Fagor 800 was really.. and i mean REALLY easy to operate..

This control

had keys for standard operations.. turning, facing, chamfering, threading.. and so on.. just pick an operation, key in coordinates ( basically a bounding box.) and hit the green button.. get coffee..

So, next moring, my boss discovered that i had found out how to operate this machine.. so when we finally got a CNC mill.. i was among the first to be trained

This machine was fitted with a Heidenhaind TNC 410.. same principal applied here.. instead of fixed buttons for operations, it had softkeys.. when writing your program.. you started by making the file, entering a solid block shape for rendering, and pick a tool.. then.. hit "Cycle def" pick a cycle from the softkey menu, enter parameters, move to position, execute cycle.. well.. i guess most of you know how to operate a CNC like this..

I believe Siemens is quite the same.. and even Fanuc now has some of this functionality in their controls.. i have only limited experience with Fanuc, and personally i don't like em.. small screen.. key-switch for about everey mode-change.. a lot of extra things to do.. i found it messy to operate..always with one hand on the keyboard and one on the keyswitch..

I personally think a Softkey based User interface is THE way to go.. the later Fagor 8050 CNC controls we got, had a profile programming system, that allowed you to program all kinds of profiles with limited information, similar to FK on a "Heidi".. everything worked with softkeys..

Then.. i built my machine.. and i found Zeus.. everything was done with.. softkeys.. on a regular PC. no need for a fancy console-keyboard.. just a PC Keyboard.. the F-Keys enabled you to enter all modes of operation.. i found it GREAT!.. i installed it on my PC to check it out.. and without ever using a manual, i was familiar with it within 5 minutes or so.. why?.. it worked Just like the old Fagor and a bit like the Heidenhain..

I've searched the internet for Windows based CNC control programs.. but found a lot of rubbish.. i don't like the idea of keyboard shortcuts.. you have to memorize them, or put them on your screen.. that makes a cluttered screen.. and i don't like cluttered screens.. in fact.. i hate them..

When i first discovered EdingCNC, then still called USBCNC, i found a user interface with a limited amount of buttons on the screen.. i was'n impressed.. but i saw the potential of this control, because of the programming posibilities.

I met Bert Eding shorly after i had discovered his program.. and we teamed up.. that's all..

Why did i design the user interface this way?.. because.. well.. i just wanted what i was used to in my professional career at home.. i wanted something with the same use of operation als the Fagor, the ZeusCNC control, Heidenhain or the Mitsubishi CNC on the Wire EDM.. the Brother CNC was a different cattle of fish, but also very easy to operate.. it had a rotating switch, with different machine modes,

so, when starting.. turn all the way to the right.. and hit "DRIV" then turn all the way to the left.. MEMO.. and open a program, or make one..

i am well aware of the fact that on some CNC programs for Windows you can make your own user interfaces.. but.. i've never ever seen one that even remotely looks like the logical layout with softkeys..

Most professional CNC's use softkeys.. and if you make use of those.. you can easily do with a standard PC keyboard..

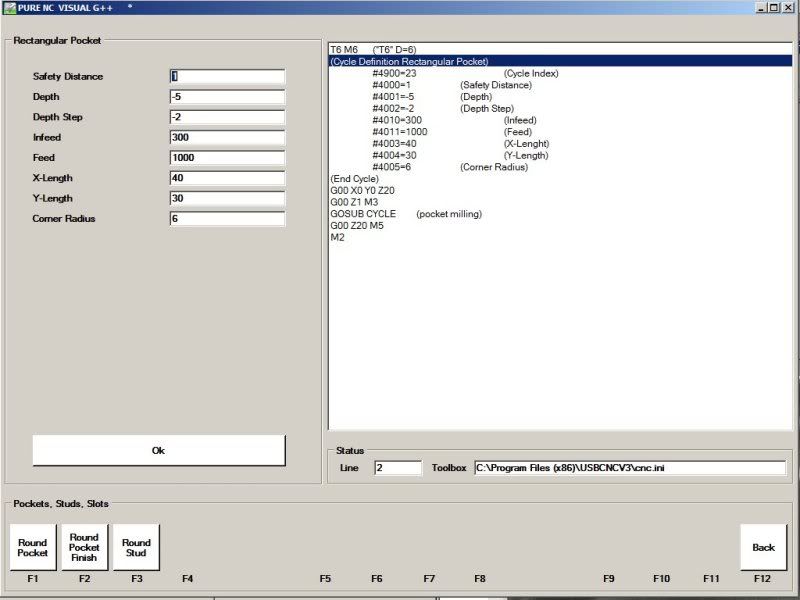

i'm quite good at programming, if i may say so myself.. when i started working with EdingCNC, i wrote a number of programs for making pockets and things like that..

Bert then introduced the Macro.cnc file.. one can store Subroutines in that file, and call them from a loaded CNC program.. i had to find a way of creating programs with parameters and a call for the right subroutines.. so i learnt some visual basic.. and i started writing Visual G++

It also operates with softkeys.. and i had it tested by a friend of mine who only worked with a Mazak control.. he figured out how this worked within 5 minutes..

How Come?.. well you only see the keys that are relevant at that time.. wrong menu?.. there's always the back button (F12).. i know a lot of hobby machinists that have changed from Mach to EdingCNC, and they love the layout.. yes.. i am proud of the User interface of EdingCNC..

I do have that Fancy controlpanel.. and i've programmed a lot of keys to get me to some modes in one push of a button.. For handwheel operation, i'd have to push F12, F9, F9 to get there.. i programmed this sequence in the Handwheel key on the panel.. so all i have to do is push the handwheel button.. load a progra?. F12, F4, F2.. or simply push the PGMMGT button.. , MDI?... F12, F6.. or.. the MDI button.. it's not that you NEED a console like that.. it just makes life a bit easier, and acces to some modes quicker.. also.. because i have worked with Heidenhain controls for 8 years.. i do everything by Muscle-memory.. like in any car.. headlight switch on the lefthand side, indicators on the left, wipers on the right.... Gearstick in the middle, or on the right if mounted on the steering collumn...

Most controls are somewhat standardised, on motorbikes, Clutch on the left, front brake on the right, throttle on the right, Gearshift pedal on the left, Brakepedal on the right.. .. on a bicycle, rear brake left, front brake right. all the same..

Since Most professional CNC's use softkeys, i thougt it was a good idea to use that system for EdingCNC as well.. just like Zeus did..

Oh.. and i almost forgot.. I also worked with a CB Ferrari CNC machine.. that control was also PC based.. it indeed had a standard PC keyboard.. and.. you guessed it.. all modes were accessed with F-keys.. (and.. with a DosShell one could easily switch to DOS to write Code in the basic DOS editor.. with all Cut and Paste functionality..

I've worked with a Fadal CNC also.. the different modes were accessed with keycombinations.. i found that terrible.. it took me quite some time before i fealt comfortable with that control..

-

01-21-2015, 06:01 AM #419

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 1189

Re: My First CNC, own design, buidling in progress

May i also through some pictures in

- Umbau Bedienpanel - tkamsker but there are too much Buttons we will change it for a Keyboard with mouse for doing all ui Based stuff like getting g Code file from Folder and so the Setting on machine and standard Run is done yust by an 25 Button One LCD and One Encoder mpg ,.. But inreally like that Diskussion here ,..

- Umbau Bedienpanel - tkamsker but there are too much Buttons we will change it for a Keyboard with mouse for doing all ui Based stuff like getting g Code file from Folder and so the Setting on machine and standard Run is done yust by an 25 Button One LCD and One Encoder mpg ,.. But inreally like that Diskussion here ,..

Gesendet von iPad mit Tapatalk

-

01-21-2015, 06:45 AM #420

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 414

Re: My First CNC, own design, buidling in progress

Arie,

For what it's worth, I think you knocked that GUI out of the park when it comes to understandability. I downloaded the program and find it refreshing to look at. I can see where you have made things really easy to use keyboard emulation for external control.

There are still some things I have been looking for, like settings for radius start/end point tolerance adjustments and I don't recall finding settings for debounce on input lines.

Not that you have to point them out to me. I have a few small machines underway again, and I'd certainly like to try this control in order to compare it to Flashcut. We'll see what happens when I get to that point.

Otherwise, great job, and it seems you and I think alike when it comes to the importance of a proper gui. A good DEFAULT gui is a must !Chris L

Similar Threads

-

more progress..

By adam_m in forum DIY CNC Router Table MachinesReplies: 0Last Post: 11-26-2013, 03:56 AM -

Design In Progress

By JoeDawg in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 10-07-2008, 07:48 PM -

My First Router Design & Progress

By watsonstudios in forum CNC Wood Router Project LogReplies: 40Last Post: 07-22-2007, 09:19 AM -

Looking into buidling an Auto-start RPC

By Wendell in forum Phase ConvertersReplies: 2Last Post: 10-12-2006, 03:03 AM -

Alibre design in progress

By xyzcnc in forum Uncategorised CAD DiscussionReplies: 10Last Post: 06-07-2005, 06:49 AM

Reply With Quote

Reply With Quote