damnit.... didn't know you were giving htem away on the other forum

I was about to cut my double sided maze....

so day

Results 401 to 420 of 648

Hybrid View

-

01-15-2015, 11:29 PM #1

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: Big Bamboo - New Machine Project Started

-

01-17-2015, 11:32 AM #2

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: Big Bamboo - New Machine Project Started

Hi Jerry,

Trying out your Dovetailmaker tomorrow. Made the jig to hold the work at 15degrees today, but this looks like another winner.

-

01-18-2015, 10:52 AM #3

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: Big Bamboo - New Machine Project Started

So I played with FingerMaker and Taimaker today and found these just as easy to use as Mazemaker. Will have to start saving ......

I would like to see the same things as I suggested with Mazemaker, but these are only minor issues ( Add an S command, etc).

I didn't thk these were too bad seeing it was using some ply that wasn't totally flat.

Attachment 264824Attachment 264826

Attachment 264828Attachment 264830

-

01-19-2015, 01:59 AM #4

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

-

01-26-2015, 04:43 PM #5

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

Thanks for the feedback Alan! The problem with the perimeter is that I am using the same algorithm for the rectangular mazes and the free-form mazes with blocking pattern. The program starts scanning the matrix until it finds the first maze cell (which is the very first one for rectangular maze) and then starts wandering along the edge of these occupied cells like a blind person tapping around with a stick. But it may be possible to exclude the diagonal cells from being found as "empty". I need to think about that.

Actually, I had originally intended the perimeter cut only for the free-form mazes because it is really easy to do a rectangular cut of any shape and size with and without rounded corners with the usual CAM programs. But I can see this may be a problem if somebody does not have a 2d CAM.

Your maze is looking good! I also have to check the branching conditions. I believe I had a feature in there at some point that prevented 4-way crossings. Not sure what happened to it since I stopped working on the software for almost a year before I picked it up again last fall. But I will have another lookBox Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

01-27-2015, 01:39 AM #6

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: Big Bamboo - New Machine Project Started

Im still waiting for my "lolipop" bits to arrive. Ive managed to source some ball bearings of different sizes (got one of the apprentce technicians to crack open some old gearbox ball races). Hopefully I will be able to have a bit more of a play with the maze creating next week. Ive got a week off work next , and once I have finished some projects for SHMBO, I'll get back into it.

Or, you could learn to write Gcode manuallyActually, I had originally intended the perimeter cut only for the free-form mazes because it is really easy to do a rectangular cut of any shape and size with and without rounded corners with the usual CAM programs. But I can see this may be a problem if somebody does not have a 2d CAM.

Nearly 30 years ago, I worked as a CNC lathe/Machining centre operator, then setter, and finally writing the Gcode for 4 lathes and 2 3 axis centres. Back then, we had no CAD software, it was all done with pencil, paper, calculator and a knowledge of trig, and dont get me started on the dramas and amount of work involved with tool nose radius compensation! I would have loved to have had the CAM software available today, it would have made life so much easier.

-

03-09-2015, 03:28 PM #7

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

I use inch size balls and cutters of same size. The software has a function to make the channel larger than the bit. E.g. for a 1/2" or 12.7mm ball I make a 13.2mm channel. You need the clearance to avoid friction with some remaining wood fuzzies.

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

01-18-2015, 01:19 PM #8

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1543

Re: Big Bamboo - New Machine Project Started

The smallest ball end (lollipop) cutter I can find seems to be about 10mm (a little of 3/8ths) - has anyone done any better? I'd ideally like <1/4" so a double sided maze could be done in 3/4" material or less. 1/8" bit would be great, but I don't think they exist...

Edit: Found some a little smaller at 9/32, but cost $59+shipping (Speargun Ball Router Bits | Plunge Bit & 1/2 inch Radius)7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

01-19-2015, 02:01 AM #9

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

02-06-2015, 03:50 AM #10

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

I left the maze software project alone last week and went back to the finger joints...

after somebody on the Vectric forum asked about options to make joints with included angle other than 90 degrees (i.e. perpendicular boards) I realized this could be achieved easily with the software, at least for acute angles.

So I published a new beta version that allows for joint angles between 22.5 and 90 degrees and allow that way for making triangular or star shaped boxes and frames with finger joints.

I am not sure if this is just a crazy idea but in case somebody wants to try here is the download link.

So far I did only a simple test (see below) and obviously there may still be bugs, but that is why it is a beta.

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

01-18-2015, 01:30 PM #11

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 711

Re: Big Bamboo - New Machine Project Started

http://www.harveytool.com/prod/Under...-270-_127.aspx

I don't know how well these work on wood, but it may be worth a try.

-

01-18-2015, 01:41 PM #12

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1543

Re: Big Bamboo - New Machine Project Started

Nice. I'd glanced at that page before but discounted them because they are for metal and looked like they had heaps of flutes.

However, the smaller sized ones have 2 flutes which could work.

The largest 2 flute they have is 3mm. 7/64" (~2.77mm) balls are not hard to find and should have plenty of clearance.

I've sent a few emails to makers of undercutting end mills to see if they'll ship internationally. Looks like those located in the US shouldn't struggle.

Jerry: What's the ideal ball sizing vs cutter? I believe you specify multiple passes for clearance, so does a 1/2" ball work with a 1/2" cutter? If we use slightly undersize balls can we only do one pass and speed up work time significantly?7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

01-19-2015, 02:10 AM #13

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

For the ball end finish pass it will always make 1 pass forward and one pass back (with offset to achieve specific channel diameter) and then do the same thing one offset distance higher. I found that method not only allows for widening the channel a little beyond the ball end bit diameter but also makes sure that all wall sides of the channel are cut in "conventional" mode, minimizing fuzz and chipping.

You can do a slot and ball end diameter of same size but it will not allow you to get much of an undercut to hold the ball captive. It will probably fall out on channel branches.Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

01-18-2015, 08:54 PM #14

Registered

Registered

- Join Date

- Nov 2013

- Posts

- 82

Re: Big Bamboo - New Machine Project Started

Jerry,

I know you have created the dxf export for single sided mazes. Could you also add the export for at least the top side for double sided?

Also, how to get apply updated values without generating a new maze pattern?

ThanksCustom 24x24 MDF, 1/2-10 5 start,425 OZ KL steppers, KL-4060, C10 BOB, 48v PS. VCarvePro V7, LinuxCNC, Craftsman 1.75Hp 1/4" router.

-

01-19-2015, 02:15 AM #15

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

That is something I am working on (well, if I would not have to do some business travel at the time). I believe I can generate dxf for 2-sided mazes as well but need some time to work it out.

For parameter updates I need to better distinguish between simple dimensional changes and systematic changes that require a new maze anyway. Just something else to improve.Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

01-25-2015, 11:27 PM #16

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 711

Re: Big Bamboo - New Machine Project Started

I'm still having fun with this, great program.

I will make 2 more feature requests.

1. Have an option to make the perimeter have square or rounded corners, in addition to the 45 degree bevel that is the only option now.

I like to run a roundover bit to smooth the edges, but I can't go full depth or it would cut into the ball channel near the corners. If there were an arc there, it would be no problem.

2. one more extra boundary parameter for only the X dimension, so that it can be widened enough to integrate handles to the sides of the maze.

Thanks.

-

02-04-2015, 01:14 PM #17

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

-

02-04-2015, 04:06 PM #18

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 711

Re: Big Bamboo - New Machine Project Started

No excuse necessary, I wouldn't know what kind of wood it was if it didn't have a sticker on it when I bought it.

It's Bolivian rosewood. It seemed like the hardest wood I had on hand, I was hoping get rid of splintering, but there was still some pieces that chipped off when slotting.

-

04-12-2015, 05:14 AM #19

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

Short Video...

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

04-12-2015, 05:12 AM #20

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Big Bamboo - New Machine Project Started

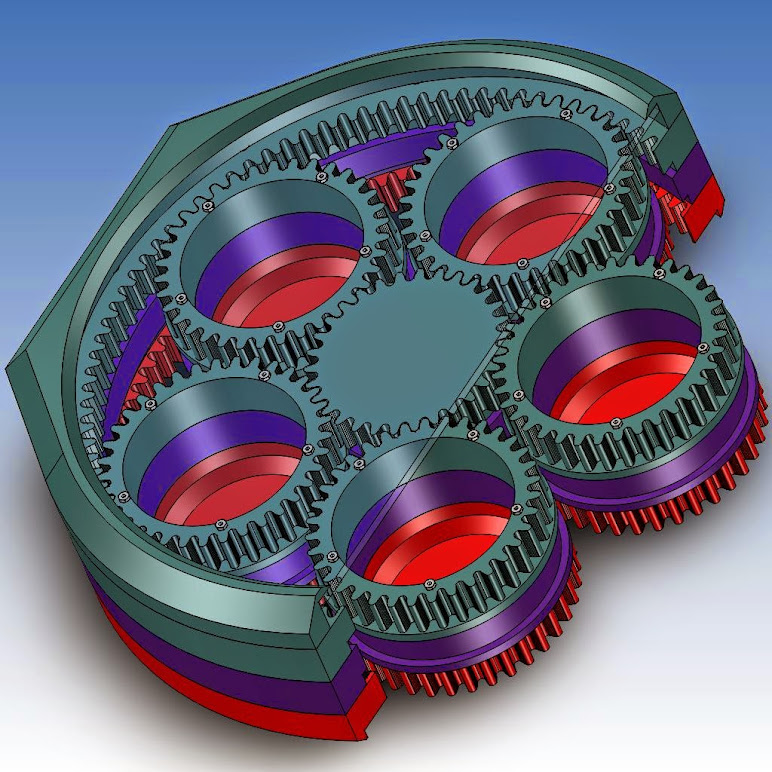

I started looking for a design of a watch display box for a birthday present and it ended up as a rather complex piece of equipment. Actually I had to do this twice, since the first version kind of worked but not smoothly enough. This second version seems to work very well.

CAD design

All parts cut out

Assembled with wooden hinge

Complete

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

Similar Threads

-

7 x 10 project started

By blades in forum Mini LatheReplies: 125Last Post: 01-25-2017, 05:27 AM -

CNC Project Started

By NotSqueaky in forum CNC Wood Router Project LogReplies: 8Last Post: 09-10-2014, 12:41 AM -

New Project Started

By Rumblebelly5 in forum Joes CNC Model 2006Replies: 1Last Post: 09-15-2012, 10:50 PM -

My 4x8 project has started

By MetalHead6263 in forum Plasma, EDM / Other similar machine Project LogReplies: 37Last Post: 01-31-2012, 07:30 AM -

Started new project

By rustamd in forum DIY CNC Router Table MachinesReplies: 55Last Post: 05-31-2009, 04:12 AM

Reply With Quote

Reply With Quote