Hi all,

another member of a dutch scalemodeling Forum gave me this link, and now i got here, i might as well share my designs with you.

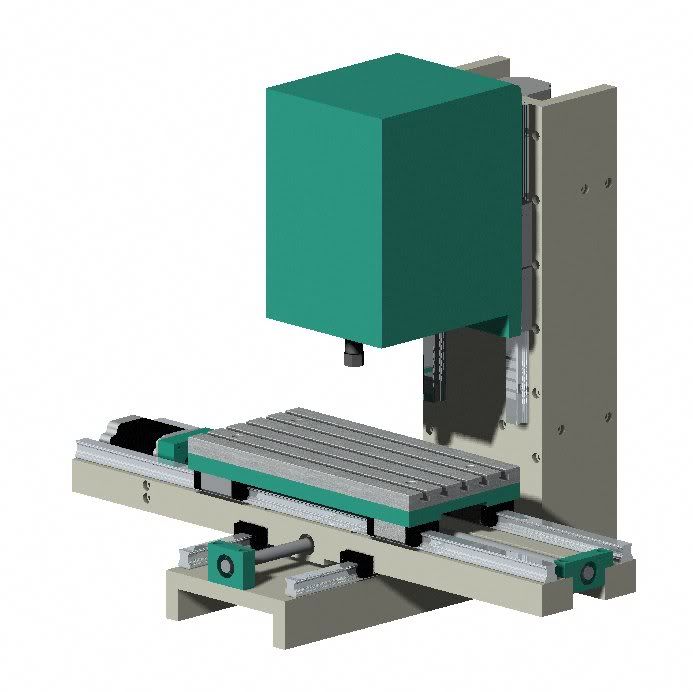

last summer i got a PC and 3 stepper motors, to fit to a 3-axis milling machine, but i have one problem.. i'm a professional tool maker, and i want the quality that i have at work ( Bridgeport VMC800 ) so i designed a 3 ( 4th axis will be mounted on the table ) machine.

Workspace will be 280 x 140 x 165 millimeters ( yup i'm from holland.. i dont work with inches.. too many numbers behind the comma )

Maybe showing my design will rule out any design flaws i overlooked.. though building is already in progress..

i also managed to get hold of a steel cabinet 100 Cm's high, and 70 x 50 Cm's top surface.. the milling machine wil be bolted on top, and i'm planning om making a casing/shield with plexiglass windows and a TFT screen in the door(s)

Spec's sofar:

Motor 600W router, 7000-30000 RPM's 6 mm collet ( smaller collets wil be made in the near future)

stepper motors from Vexta, 2.5 A, 2.2 Ohms Nema 23

Rexroth Ballrail guides and Ball spindles.

Machine frame is made out of construction steel 15mm thick in most places except the X-axis guide bed which is 30x40 mm's 596 mm's long.

Fourth axis will be built in a Unit which can be bolted on the table ( design hasn't been made yet, i'm still searching for small 4 jaw independent Chucks.

Progress sofar: machineframe is finished, al parts are ground flat only the Z-axis milling head is still to be made, if that's finished, the rails wil be bolted on.

Results 421 to 440 of 441

Threaded View

-

01-10-2007, 11:31 PM #1

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

My First CNC, own design, buidling in progress

Similar Threads

-

more progress..

By adam_m in forum DIY CNC Router Table MachinesReplies: 0Last Post: 11-26-2013, 03:56 AM -

Design In Progress

By JoeDawg in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 10-07-2008, 07:48 PM -

My First Router Design & Progress

By watsonstudios in forum CNC Wood Router Project LogReplies: 40Last Post: 07-22-2007, 09:19 AM -

Looking into buidling an Auto-start RPC

By Wendell in forum Phase ConvertersReplies: 2Last Post: 10-12-2006, 03:03 AM -

Alibre design in progress

By xyzcnc in forum Uncategorised CAD DiscussionReplies: 10Last Post: 06-07-2005, 06:49 AM

Reply With Quote

Reply With Quote