Hi Sky, just received your invoice....I'll be doing the banking in a day or so.

I do like that laptop stand......can you add that model to the package too or will that mess up the invoice amount?

Or, if you let me know how much the stand will cost I could add it to the invoice amount total when I do the transaction.

Those circuit boards are pretty neat, hope they work as good as they look.

Ian.

Results 461 to 480 of 3662

-

10-14-2013, 03:50 AM #461

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

-

10-14-2013, 04:09 AM #462

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Skyfire, thank you for the thoughtful and informative response; I am very happy to see the new driver. I look forward to you getting your website up and running. I will very likely be getting a motor and driver from you to upgrade the spindle motor on my BF20

-

10-14-2013, 05:13 AM #463

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, a question on the computer input as I'm out of my depth here.......can I use a laptop with Win XP and USB, or will the controller only accept a desktop with a serial Input?

I've heard that you need a serial input, so a laptop won't be suitable...is this so or does the controller for the SVM-0 have a USB input?

I have both a laptop and a desktop available for use, but the laptop being a complete computer with monitor all in one would be neater.

Ian,

-

10-14-2013, 06:33 AM #464

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi handle,

sure, the laptop stand is avaliable easily. I updated the invoice and send you again. just add the net cost of this stand..It's a pretty nice one with adjustable gas strucks inside.. not the common adjusting screw one. Please check the email for the new invoice...

Thank you for the ordering. I will put your SVM-0 into the production list now!:cheers:www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-14-2013, 06:51 AM #465

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

The basic controller configration is a parallel port one using LPT port of the computer.. USB controller is avaliable too to update the controller system.. I have two avaliable USB controllers can be an optional part. I think a 4 axis, 200Khz USB controller should be enough. It has 32 input and 21 output can be used to expand many applications like an extra control pad or MPG etc.. I think you can pick it ..or upgrade some other popular controllers in the cnc community. There are a lot of choices now...

I agree that the laptop will be neater and more convenience. So if your laptop doesn't have the LPT port, I suggest you select an USB controller for it..LPT is really a little out of time www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-14-2013, 07:07 AM #466

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-14-2013, 10:29 AM #467

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, thanks for that, got the revised invoice OK.....4 axis is enough for any needs.

It is my intention to go to a 4th axis movement eventually for some ideas I have, as and when etc, so that base is covered.

Ian.

-

10-14-2013, 10:40 AM #468

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-14-2013, 10:56 AM #469

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

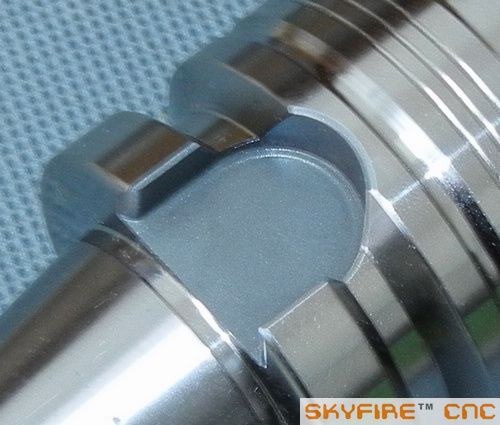

Hi Skillalot, I got your BT30-ER32 holder and pullstud in hand now. I'm sure you will like them. Here are the pictures.. The fist sight I really doubt the holder is made of stainless steel..

every corners are perfect grounded. no any sharp corner or mill trails.

every corners are perfect grounded. no any sharp corner or mill trails.

the plastic package:

the holder body. very shining ...

The pullstud:

The detailed corners.. Sorry my hand shaked. LOL

So we can see, the 20CrMnTi tools has different color with 40Cr ones. Of course, 40Cr is not bad with proper treatment. But not as good as 20CrMnTi. Most of current economic tools on market now is 40Cr ones.

The BT30 spindle actually arrived too but I need to take it back to office for pictures tomorrow. so I can send out all of your goods tomorrow.

And Handle, your ISO20-ER32 will be the same quality.. I will ask my tool supplier can mark SKYFIRE brand on them and all my next QTC tools. I plan to provide two level tools in future,, high class 20CrMnTi ones like this.. and lower economic 40Cr ones-----Of course, all necessory treatment will be done too.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-14-2013, 12:23 PM #470

Registered

Registered

- Join Date

- May 2007

- Posts

- 99

Looks good

Can't wait to have that spindle home

Can't wait to have that spindle home

-

10-14-2013, 04:54 PM #471

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Wow Sky, you are spoiling us something rotten......LOL.

The finish on those tools is unbelievable......I think I'll put them in a glass case for display and just look at them for fear of making marks on them, absolutely well worth the price.

BTW, if it is possible, can you add a serial number marking to the mill name plate, so that I can brag that it was among one of the first off the line.

In years to come this mill will become a collector's item.

Ian.

-

10-14-2013, 06:25 PM #472

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

USB is a serial port; hence its name, as opposed to the printer port, which is a parallel interface... The normal difference is that (for most home uses) a dedicated computer with parallel port is used as the "pulse generator" for the stepper drives, and most USB devices offload the pulse generation from teh CPU of the computer to a dedicated processor. That's why laptops are generally not used with parallel ports and Mach3 - the power saving modes of the laptop's CPU can change the "pulse timing" and cause problems. This is not the case with an external controller...

I will say that I too am an early purchaser of an SVM-0; in fact mine is the one with the 2.2kW spindle, since most all my work is in aluminum. I have some projects I want to work on where I demand more than what either my DIY machines can produce, and I hope to fully exploit the capabilities of my new machine. I'm also working on a 4th axis design, but will try to make it as simple as possible with as much off-the-shelf parts I can.

As to g-code writing... I've made some small programs for simple parts, but it is so much easier to use a dedicated CAM software. Even a basic one will do. If you plan to do any 3D contouring there realy is no better choice than to get a decent CAM package. I don't mind handwriting code but it's more fun to see parts being made! And I happen to own some pretty competant CAM packages that I feel will really let me fully utilize my new machine!

-

10-15-2013, 01:45 AM #473

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi, thanks Louie, I'm learning by degrees......I probably meant parallel port, but not being too savvy in that direction the port or input definition escaped me.......this is something like "going to the bathroom" when you really meant the toilet.......LOL.

So, I need a CAM package.....I assume then that I would never be able to write any significant G code programs for a CNC mill to make things that could be done faster on a manual mill.

Does that also mean I need to create the part with a cad program, convert it to a DXF file by running it through a CAM package to get the machine to work?

I have Turbocad Deluxe 2D/3D version 16, but will have to learn to use it, as I did most of my parts drawings with Cadkey light some years ago, and that was a DOS program, but oh so easy to use.

The World of CNC is opening it's doors, and the first step is the machine acquisition, so as the longest journey starts with the first step that's where I'm at.

Now all I need to find out is what is a suitable CAM package.

Ian.

-

10-15-2013, 05:44 AM #474

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

You should be able to export a file in TurboCAD as a DXF or DWG file, which most all CAM software supports. If you have a 3D CAM software you can read 3D parts. There are good reasons to design in CAD first. You may want to check clearance or fitment between two parts in an assembly, and you can do that in 2D as well as 3D. You may need for example to make a bracket for a part, and you can find the CAD online for the part, and extract all the geometry you need to make that part. There are a wealth of CAD files for parts you may want to make, as well as software like Gearotic Motion to generate CAD of different gears, or Sprocketeer which is free and can make different sprocket profiles.

With CAM, you can have your tool database saved, along with feeds and speeds for different materials, use different tools for each operation, and different toolpath strategies. Simulation helps a great deal, and I always run it to check myself - like order of operations or approximate cycle time - before cutting a complex part or doing a small run.

My basic litmus test for CAM software is pretty straightforward - I download the trial software, and attempt to create toolpaths to one of my files without needing to read the manual or help file. If I can't do it in an hour, I move on. Cut2D by Vectric is not really intended for the metalworking crowd, but it can do most all pocketing, profiling, and drilling operations you can need, as well as some very basic drawing tools. You can set your plunge and feed speeds, as well as ramp in to cutting depth. If most all you do is in 2-1/2D it covers most everything. It even has simulation, and you can create toolpaths fro TrueType and OpenType fonts. And it's only $149.

Most inexpensive 3D CAM software that I've seen don't give you much control as to how you can machine a part. There are workarounds but they can be a pain. The better software will allow you to use a different strategy for different surfaces or regions of a surface. I cut quite a few guitar parts where I need to use different tools and strategies for different areas. This software is not usually cheap but I'm glad I have it. I've also leveraged constant engagement (or high-speed) toolpaths for my machine, which isn't the most ridgid and doesn't have a high-power spindle. I hope to apply what I've learned the past few years with this new machine, and am pretty excited about the potentials....

-

10-15-2013, 11:37 AM #475

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Louie, I'm just realising how much I have to catch up on just to be able to switch the machine on, and getting down and dirty with a sharp cutter is going to be a breath taking moment......LOL.

$149 for the CAM program is not too bad....well within reach.

I know now how somebody with no lathe knowledge feels when they've just bought a new lathe and want to know what happens next.......CNC is so much more different to the manual mill approach, but at least I know why a cutter needs the speed and feed for the material being cut.

I've just paid for the mill so now the big wait is on.

Ian.

-

10-15-2013, 12:23 PM #476

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Yes it's a fun thing to watch something you've designed and rendered and simulated on your computer becomes something you can actually hold and use!

As to CAM, I know of a few guys in the Woodworking section that invested loads of time and money on some great machines, only to hobble them with workarounds with freeware. They cut simple parts but never really realize the potential of their machine, because they didn't take CAM into consideration.

If I had to hazard a guess, I'd say there might be some getting used to going from manual cutting to CNC control. You'll have a spindle capable of probably double the speed of what your manual mill can achieve, and these small steppers are capable of remarkable anounts of forces, at speed! Even with my current CNC router setup, I'm still surprised how fast I can machine aluminum, and my machine is nowhere near as ridgid as this mill.

Yes we're waiting, but the payoff is big!

-

10-15-2013, 01:10 PM #477

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi skillalot, your spindle is checked today and packaged up with the strong wood case.

Here is your BT30: vaseline coated and sealed with plastic film. I think I'd better not open it now..lol

Placed your toolholder, pullstud in, and gloves, wipe cloth.

Fill in the cloth again and packed up:

So it will be sent out from tomorrow morning.. Track number will be sent to you later. www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-15-2013, 01:19 PM #478

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi handle.. yes, I'm satisfied with the holder too.. even more than I expected. So now I would expect they will do same level on your holders.. LoL

It's a goo idea to add serial number to the machine.. I will see how to do it I really hope my brand can last that long to be a antique but not return to stoves. hahaha

www.skyfirecnc.com

I really hope my brand can last that long to be a antique but not return to stoves. hahaha

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-15-2013, 01:31 PM #479

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Aha Louie, Thank you for the several great posts here. I quite agree with our points on the MACH software clock issues. It's clock/pulse engine is based on the Windows clock. It's a "soft clock" so may change any time---especially the new CPUs with HT technology.. older CPUS like P3 class will be more stable. But a USB controller has no such problem because its pulse engine is a "hard clock" very stable and accurate. As I can see from the KFLOP controller, a DSP may take charge of all programable functions and I/Os. and another big chip looks to be a CPLD or FPGA should be the Hard Pulse Engine... Just a guess, I'm just starting to learn it...lol

And, yes.. an easy programming software is very important for being fun but not crazy! www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

10-16-2013, 03:33 AM #480

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM