Results 61 to 80 of 235

-

03-20-2013, 06:08 AM #61

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

03-20-2013, 06:05 PM #62

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

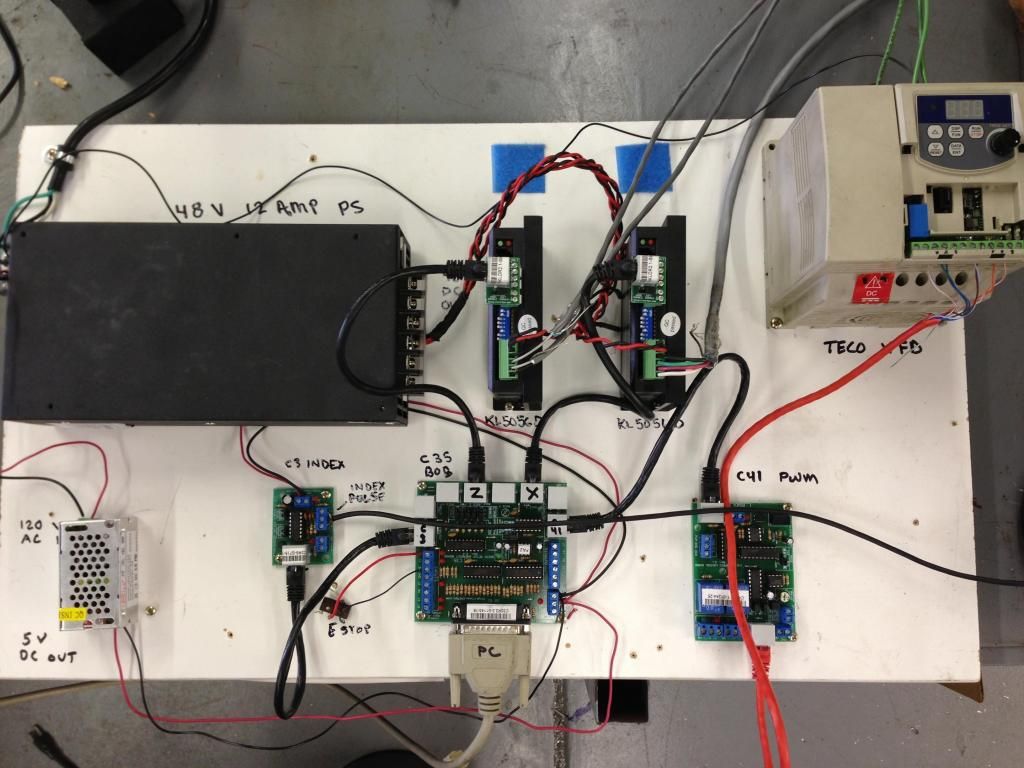

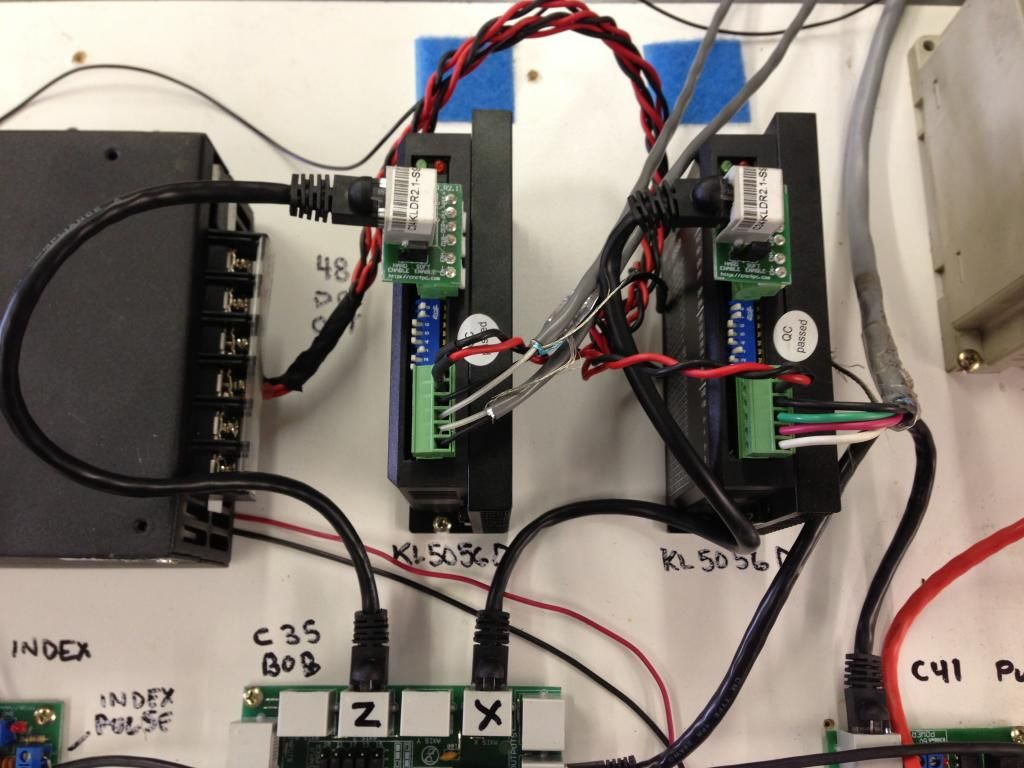

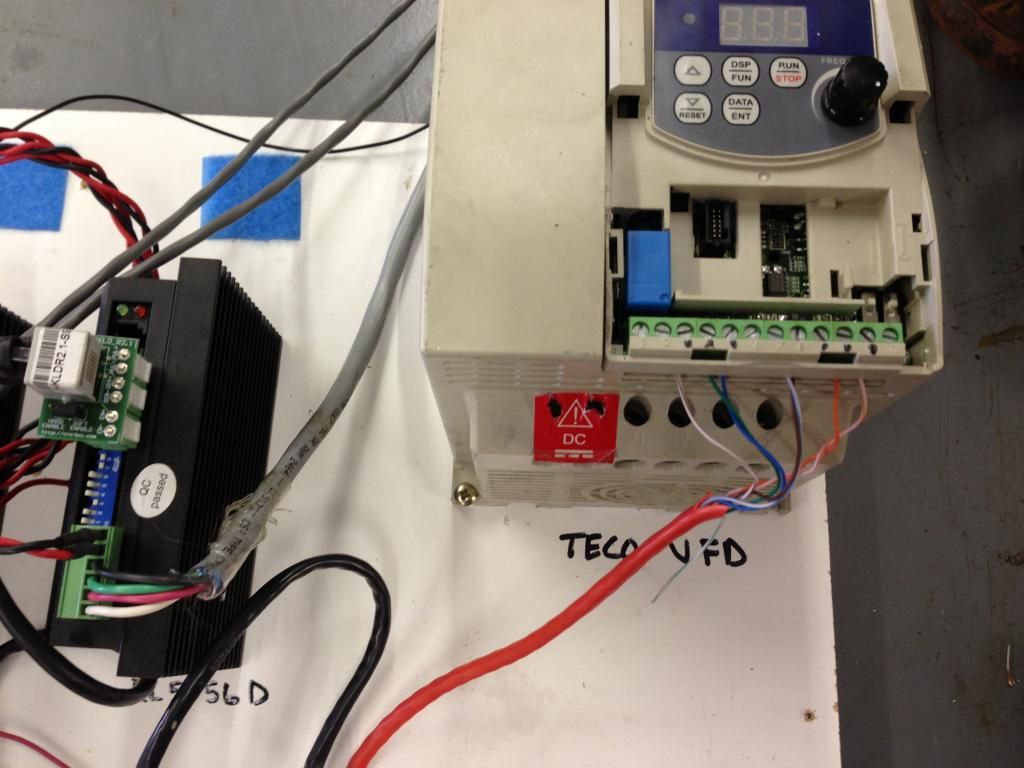

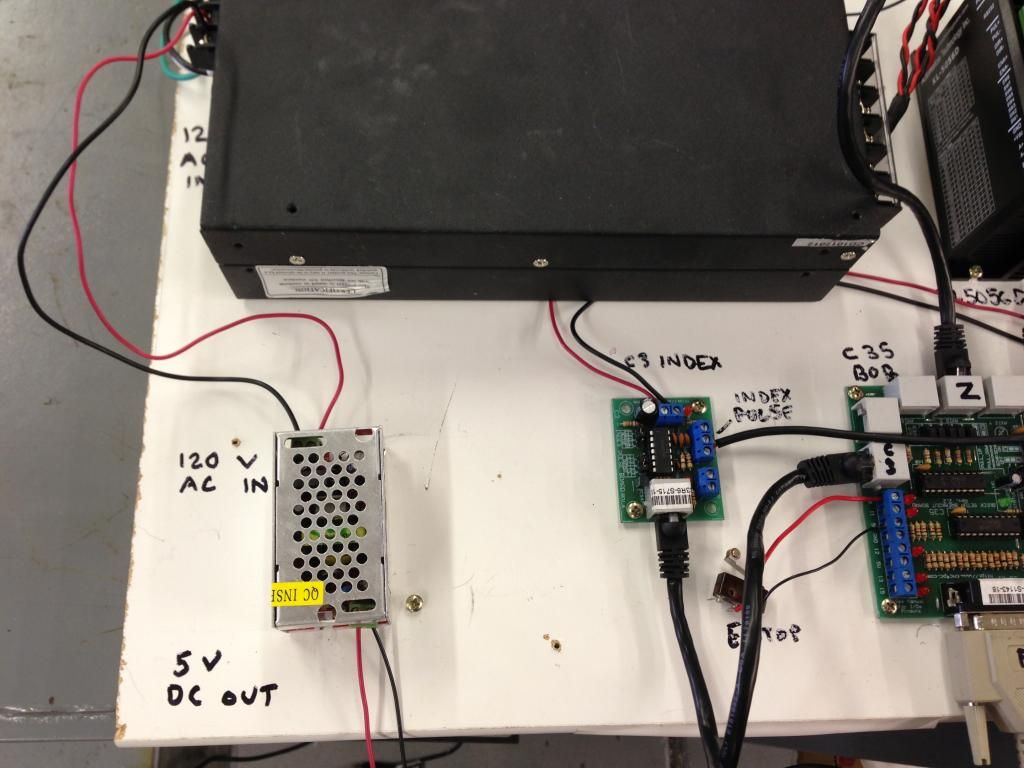

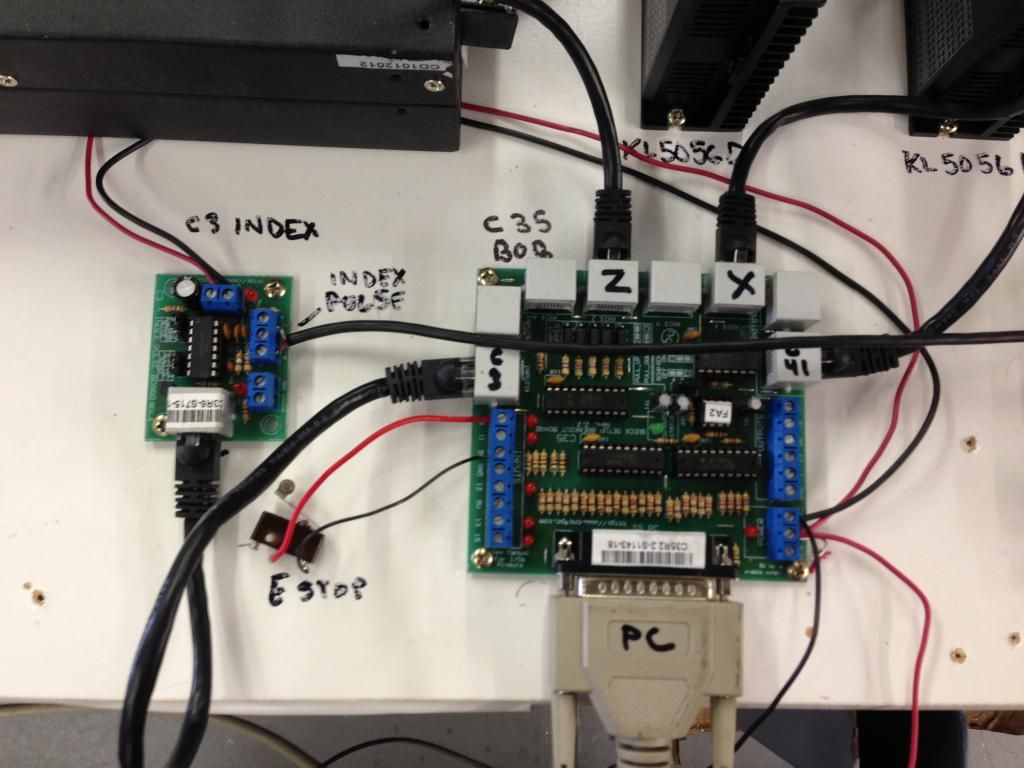

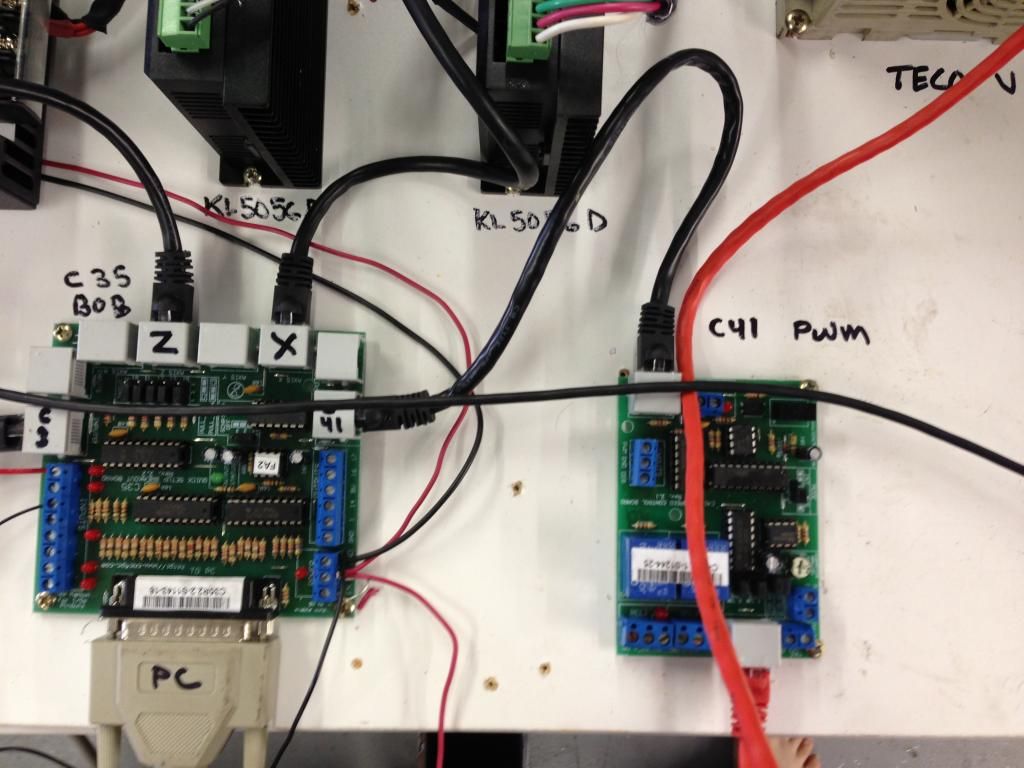

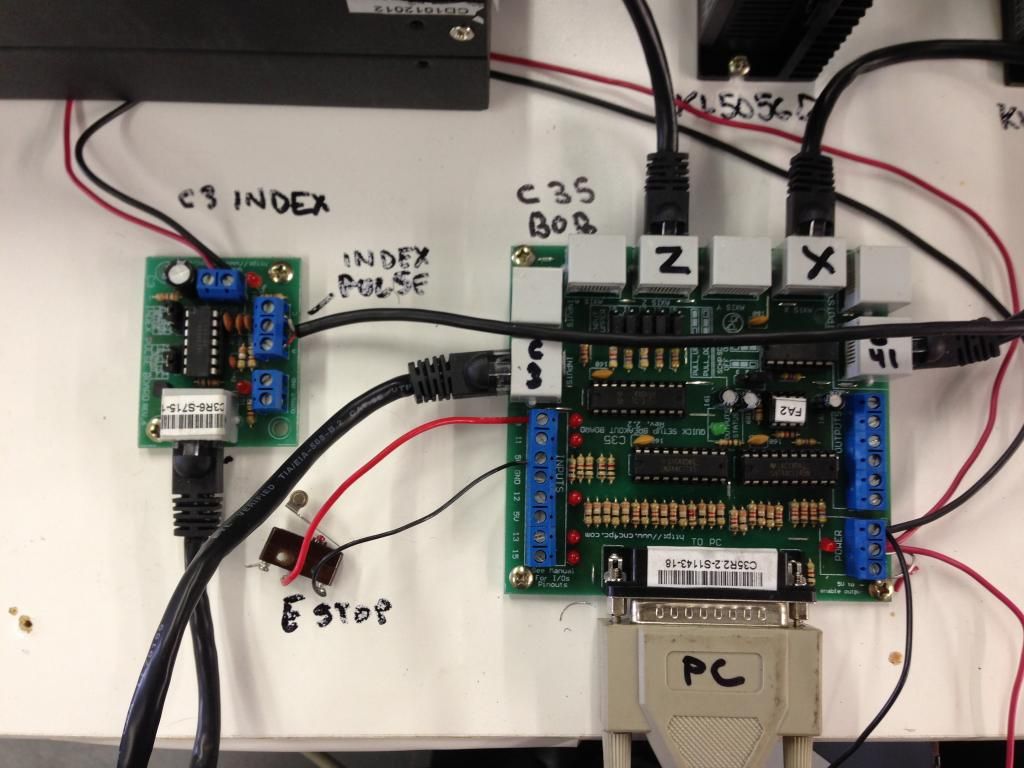

I am going to start my my lathe enclosure and electronics cabinet. Here is my feeble attempt at documenting what I chose for electronics and how they are wired before it is ripped off the board. Some things may change in the future, but this is the basic setup I have been testing with lately. One thing to note. The C41 board does not need a external 12V power supply to function correctly. I am only using a 5V DC 2amp power supply and a 48V 12amp power supply with this setup.

-

03-20-2013, 06:34 PM #63

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

I ordered an external braking resistor for the VFD from Amazon. Will see how well it works in a day or two.

Amico Ceramic Tube 100 Ohm 5% 300W Fixed

http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

The VFD will trip an Over Current error if it decelerates too hard with the internal resistor. Usually 2 seconds or less deceleration time, but it is not consistent, possibly changes with heat. Obviously if I set deceleration around 4 to 5 seconds there is no issue. This is a problem because I have not been able to out put the VFD error state to mach yet. Mach could keep running with the VFD stopped in an error state I fussed around with it the other day but didn't quite get it yet. I assume I want to have a VFD fault signal trip the mach E-stop or feed hold? When the lathe is spooled up in the 3000 rpm or higher region it does take some significant power to slow it down quickly. I have noticed that when I am in CSS mode (constant surface speed) you really need to have the deceleration set to around 1 second if things are moving fast. You really want to make sure the chuck is locked to the spindle when doing this especially in reverse. Otherwise your chuck could spin off at 3000 rpm and go shooting across the shop. Kind of awesome!!!!!!!!

-

03-20-2013, 08:01 PM #64

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 962

Turbo,

My Hitachi VFD has a relay that trips whenever the VFD faults. I wired that into my E-Stop & works great!

-

03-21-2013, 03:18 AM #65

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 509

I am interested in how that resistor works out for you. I have a Teco VFD on my lathe and I had to set the decel to pretty long to not trip (like 4-5 secs) but that is with my 6" chuck at top speed (~1800 rpm) on a manual lathe so not a real problem yet...

Looking real good - I like the surface finish you're getting.

Miike

-

03-21-2013, 01:07 PM #66Gary588 Guest

Here is a little discussion regarding the CNC4PC C6 board output voltage issues. Sounds similar to what I saw.

-

03-21-2013, 02:27 PM #67

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

gd.marsh, I enabled the fault relay output on the VFD and was able to see the state change on the BOB of the fault signal. When I get things back together I will revisit this. I think its important for Mach to know the fault state of the VFD. The braking resistor gets a lot more of a work out when running in CSS mode, especially if you are running high spindle speeds.

-

03-21-2013, 02:33 PM #68

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

03-21-2013, 02:43 PM #69

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

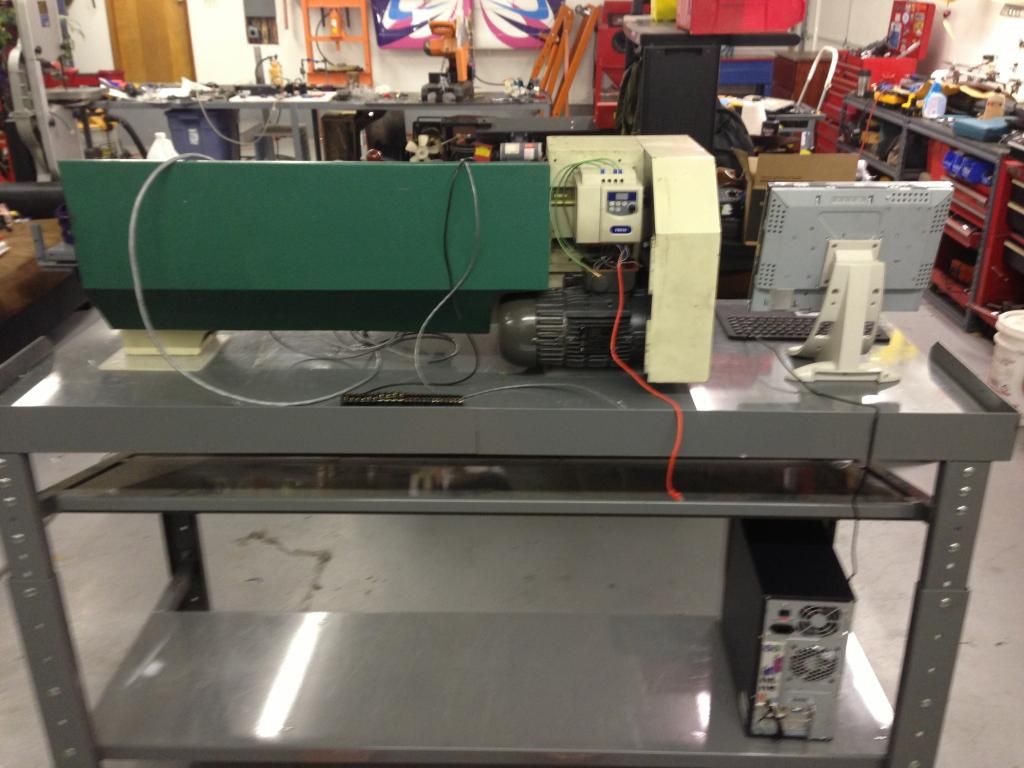

Yesterday evening I shuffled some equipment around in the shop and also moved in a bench I found at the electronics surplus store. Its a beefy industrial work bench with adjustable height. It will allow me some flexibility for placing an electronics cabinet, monitor keyboard stuff.

-

03-23-2013, 03:20 AM #70

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

OK,

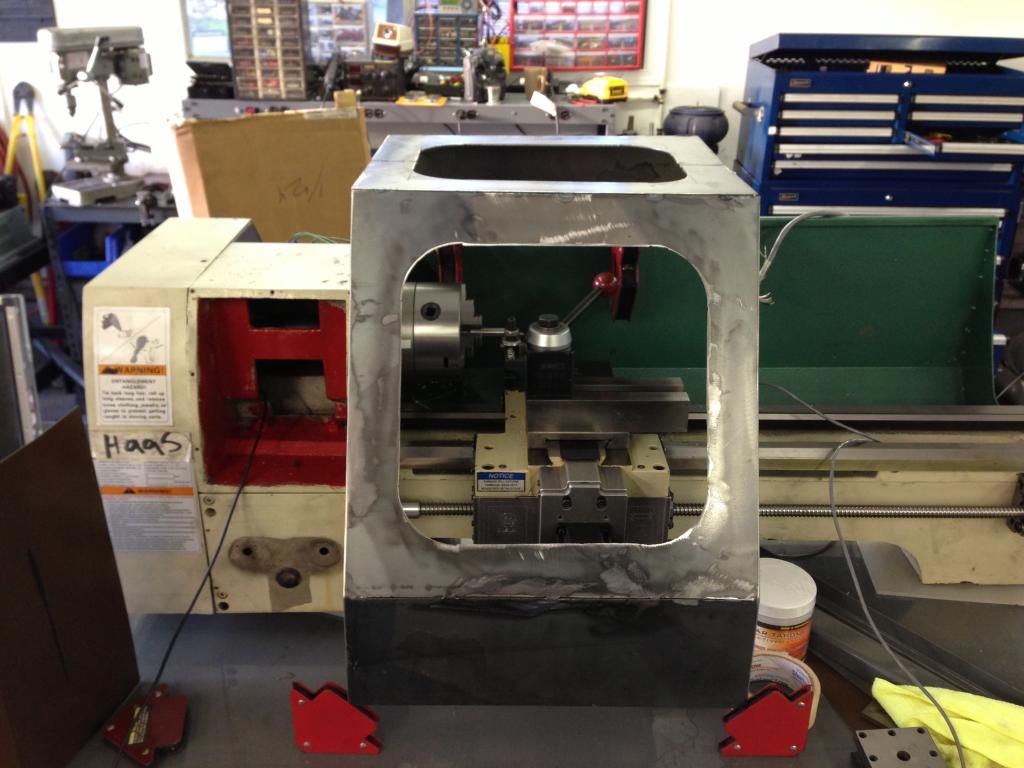

Project enclosure commencing.

This was all done manually with a plasma cutter and tacked in a few places with a mig.

-

03-23-2013, 03:24 AM #71

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

This is a sliding enclosure/door. My plan is to mount a top and bottom ground rod with two plastic slider bushings securing the door at the top and bottom. Similar to this setup.

EDIT: I decided to go with plastic sliders that I made up.

-

03-23-2013, 10:53 AM #72

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 41

Looking really sharp, and I absolutely love that bench, nice find-

Dave

-

03-28-2013, 05:07 AM #73

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Here is what I have come up with so far. Next I will finish up the enclosure, box it in a bit and weld it together. Tried my best to keep it clean and simple.

http://www.youtube.com/watch?v=tGkvItARb30

-

03-28-2013, 07:24 AM #74

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Will do the other side I think tomorrow. Starting to get rigid now.

-

04-01-2013, 04:54 AM #75

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Making some progress this weekend. Got the sliding enclosure welded up and primed.

I cut the 18GA sheetmetal with a miller Spectrum 650 Plasma.

Everything was tacked together with a Lincoln Power Mig255

I Tiged everything with a Miller Syncrowave 350.

All are all Craigslist finds.

-

04-01-2013, 07:10 AM #76

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

Regarding coolant, took the easy way out.

H8140 7 Gallon Coolant Tank System

and this.

G9622 Magnetic Base w/ Coolant Hose - 175 lb. Force

-

04-02-2013, 01:27 PM #77

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Looking good. Nice finds. Coolent should do well, but this one is much better for just a dollar more:

G9810 Magnetic Base w/ Two Coolant Hoses

If you call before they ship, you can change it.

CR.http://crevicereamer.com

Too many PMs. Email me to my name plus At A O L dot com.

-

04-03-2013, 05:08 AM #78

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

-

04-03-2013, 07:58 AM #79

Registered

Registered

- Join Date

- May 2011

- Posts

- 308

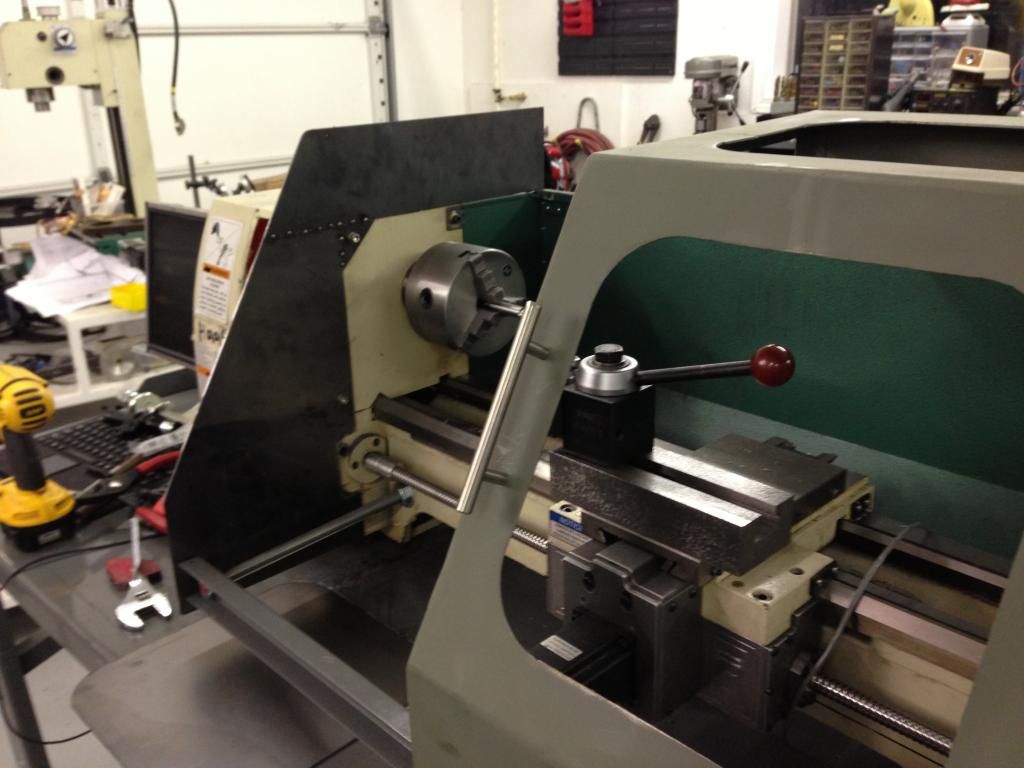

Got the side splash shield or side cover done tonight...what ever you want to call it. My shop is an absolute mess right now. Really kind of sucks, I know its gonna take a full 12 hour day to get it back in order. I'm the only one to blame. I wish I could discipline myself to 100% clean up after every step but once it gets to a certain point I seem to stop picking up. Part of the problem is that I am trying to learn this sheet metal stuff as I go. Its kind of a messy process compared to machining.

-

04-03-2013, 08:08 AM #80

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

Gorgeous. Well done man.

Are you going to extend that sideshield any further over the head? Might look nice to have a contiguous frame, especially if you use the extra space to create a pan for fluid/collection.

Similar Threads

-

Grizzly G0602 10" x 22" Lathe Conversion

By derekbackus in forum Vertical Mill, Lathe Project LogReplies: 145Last Post: 01-29-2019, 09:29 PM -

King 10x22/Grizzly G0602 CNC conversion with full enclosure

By ZincBoy in forum Vertical Mill, Lathe Project LogReplies: 5Last Post: 01-16-2013, 08:35 PM -

Grizzly's G0602 10x22 Lathe

By cobmachine in forum Benchtop MachinesReplies: 21Last Post: 02-01-2011, 03:26 AM -

Grizzly G0602 10x22 Lathe Conversion

By Steelpolish in forum Vertical Mill, Lathe Project LogReplies: 56Last Post: 01-21-2011, 11:04 AM -

About to pull the trigger on a Grizzly G0602

By akschu in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 08-28-2008, 09:36 PM

Reply With Quote

Reply With Quote