Thanks Dave and Bob,

Dave you could make a small movable stand that sits next to your machine or do what I did with the shelf on the side and then try to weigh the unit down. A box filled with sand is heavy. Just an idea.

Will

Thread: New 4x4 XYZ Gantry Build

Results 61 to 80 of 141

-

08-17-2011, 09:21 PM #61

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

-

08-17-2011, 09:26 PM #62

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Tip of the day,

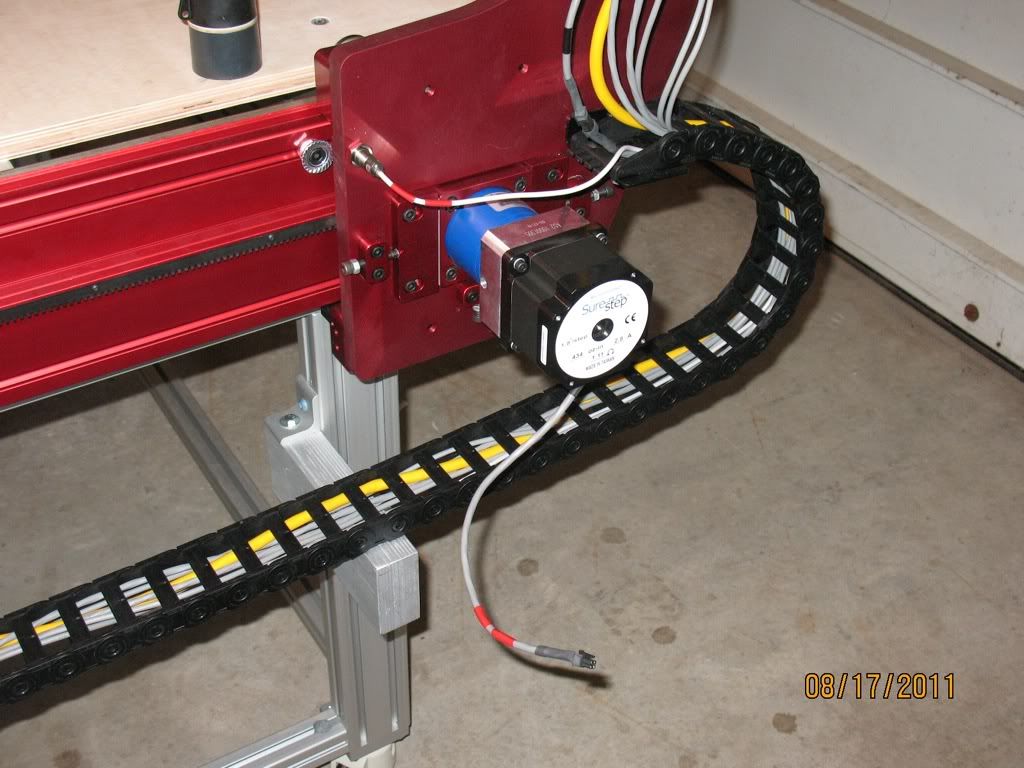

I learned many years ago when running wires to color code the ends (both ends) which will make hooking the wires up much easier. Have all the wires run and now will temp try them on the controller if not today in the morning.

Will

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

-

08-17-2011, 10:10 PM #63

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 325

Will, do remember how long your longest motor cable is? I'm going to be making my own cables and I can get an idea of how much cable to order.

That thing is really starting to look sweet. I can almost start to see the chips flyin'

BobL.

-

08-17-2011, 10:53 PM #64

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 398

Will,

Both good ideas.

I think I will go with a stand.

And either bolt or sand bag the machine. I don't think it will move often. its easier to move with bolts. ;-)

Color coding is a great idea. I just marked D shells with a sharpie. But I am not that organized.

I see that you will be cutting by the weekend.

Dave

-

08-18-2011, 01:36 AM #65

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Bob,

The new cables I got were 17' long for the far ones. With that I can place the controller under the table. If you want it away from the table get extra cable. Hope that helps.

I want to say thanks to everyone for all your help. This has been a great learning experience and will continue to be. I have a long way to go. Mach will be the hard part.

I hope in some small way I have given you some ideas that you can use or use in the future. This forum is about sharing information and for me finding people I can call a friend.

Will

-

08-19-2011, 01:00 AM #66

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Update...........

Not much done today but am learning Mach3. Added a tray shelf for the cable and a few other things. I'm really trying to make this look nice and neat. I have a small cnc now and want to try and make it the same. Any ideas welcome. Dave, take a real close look and we need to talk. I'm hoping more than just a few of us are looking at this.

Will

[IMG] [/IMG]

[/IMG]

Wires

[IMG] [/IMG]

[/IMG]

Wires on slave side

[IMG] [/IMG]

[/IMG]

-

08-19-2011, 01:40 AM #67

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 398

Will,

Did you add the holes on the Gantry Arms for the cable for the slave?

They are needed. I have not added any on mine yet. Too lazy ;-)

I think you need to move the lower mount on your cable chain back some so you can route your wires to the back of you controller.

Drop me a note when you want to chat.

Dave

-

08-19-2011, 04:47 PM #68

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

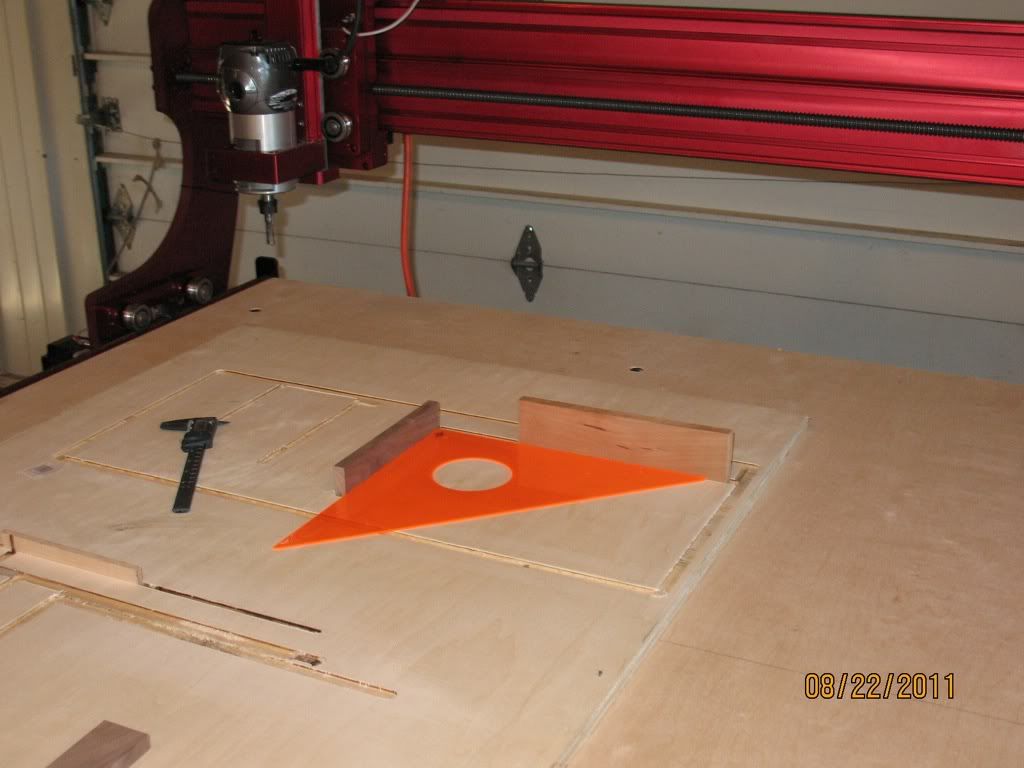

Did more fine tuning this morning, Thanks Dave for the help. Some pictures showing what I did and cut my first chips, be it so small.

Will

Checking movement

[IMG] [/IMG]

[/IMG]

Seeing if the Kent dust shoe will fit.... It does

[IMG] [/IMG]

[/IMG]

-

08-19-2011, 04:50 PM #69

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

My first cut :cheers::cheers:

[IMG] [/IMG]

[/IMG]

Checking square

[IMG] [/IMG]

[/IMG]

-

08-19-2011, 05:11 PM #70

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 398

Will,

That looks pretty square.

Is the cherry you are using for scrap wood?

I was confident you would be cutting today

Dave

-

08-19-2011, 05:18 PM #71

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Dave,

It looks like cherry but is spanish cedar. I have a bunch of it left over from when I made humidors. Just ordered my dust shoe. Will have to make a bigger cut on Sunday to check for sq then but this is very close. Did a dry run of the road runner and that seamed to work. I'm close.

Will

-

08-19-2011, 07:07 PM #72

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 406

That is one beautiful machine, good work. Not to pick nits, but are you sure your square is square? I've got a drawer full of plastic squares that aren't.

Bob

"Bad decisions make good stories."

-

08-19-2011, 07:55 PM #73

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 325

Hey Will,

Thanks for the cable measurments.

Man, you're makin' chips-Cool !! :banana::banana:

It don't matter how many, just making the first chips is a milestone. Congrats

Been trying to nail down my basic frame design, man it is tedious.

I am getting anxious for 'the call'.

Machine is looking great Will...

Hope your weekend is not full of work or 'Honey Do's' and you get some quality time with your machine this weekend. This is the FUN part, enjoy

BobL.

-

08-19-2011, 07:59 PM #74

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 325

-

08-19-2011, 08:14 PM #75

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

Thanks Bob

I know it,s sq cause I used it as designer for many years before we went with computers. I know the machine is off cause I had a 1/32" gap at the end of the cut. I,m gone till Sunday and will work more on it then. Blob if you want to see what I make look at my web site. Design's by Will home page

More later

Will

-

08-20-2011, 12:13 AM #76

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 398

Will,

Spanish Cedar, That's nice stuff.

Enjoy your weekend.

Dave

-

08-22-2011, 06:43 PM #77

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 0

X to Y is now square. Or the best I can tell until I start making larger items. Had to make some adjustments on one motor to sq it.

Now more learning Mach3 and more settings. Also have to work on t-tracks

Will

[IMG] [/IMG]

[/IMG]

No gaps in larger tri-angle

[IMG] [/IMG]

[/IMG]

-

08-22-2011, 08:31 PM #78

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 325

Looking good Will.

I've never played with syncing two motors. All this tweaking, tuning and troubleshooting bits and pieces is where you really get to know your machine. I find a certain level of comfort knowing a system like that.

I looked at your website. Nice work dude. I've only been fiddling with woodworking for a few years strictly as a hobby. Made some decent boxes for friends and family. Boxes are small enough to be easily worked in my garage and I find they can be quite challenging if your going for a sweet fit and finish using carefully chosen stock. Anyhow, nice work.

I'm still twisting and turning over placing the purchase for my extrusions. I keep going back and forth. That stuff can add up quickly. I don't mind the extrusions quite as much, but the hardware is a killer. I'm pondering if I can make my own brackets and plates using common nuts/bolts.

Anyhow, someday I'll be where your at now. Actually it may time out pretty well. I'm in Florida and the garage is not exactly comfy in the afternoon/evening. I am SO looking forward the the weather turning here. But that's months off.

Have fun,

BobL.

-

08-22-2011, 08:56 PM #79

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 398

Bob,

Have you thought about building a wood base? If I were to do again I would give it serious thought.

Will,

Its looking good.

Dave

-

08-22-2011, 09:04 PM #80

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 325

Yeah, but I always wanted to play with some of that extrusion stuff

BobL.

Similar Threads

-

DIY CNC PLASMA GANTRY BUILD OFFER

By rchacich in forum News AnnouncementsReplies: 9Last Post: 10-21-2010, 03:34 PM -

Phife's First Build. Gantry CNC.

By Phife in forum DIY CNC Router Table MachinesReplies: 26Last Post: 01-21-2010, 08:19 PM -

Want to build stout gantry CNC router

By Jrs_Farm in forum DIY CNC Router Table MachinesReplies: 7Last Post: 10-23-2009, 08:37 PM -

First build! 3-Axis Gantry-style CNC

By TheBakachan in forum DIY CNC Router Table MachinesReplies: 25Last Post: 04-18-2009, 02:10 AM -

Would you help me build my Plasma Gantry?

By Mick40 in forum Waterjet General TopicsReplies: 3Last Post: 11-15-2007, 12:58 AM

Reply With Quote

Reply With Quote