Thread: A benchtop cnc lathe build

Results 81 to 100 of 296

Hybrid View

-

09-15-2007, 10:25 AM #1

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

-

09-17-2007, 04:48 AM #2

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

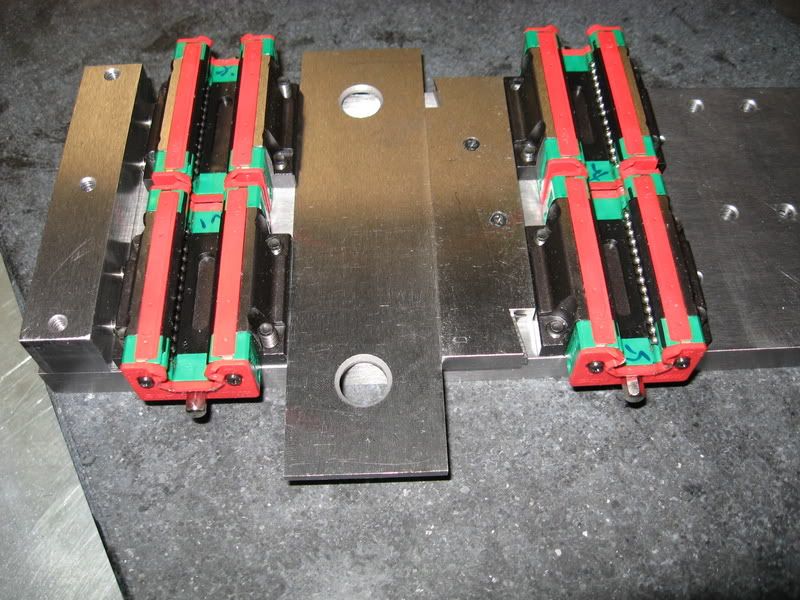

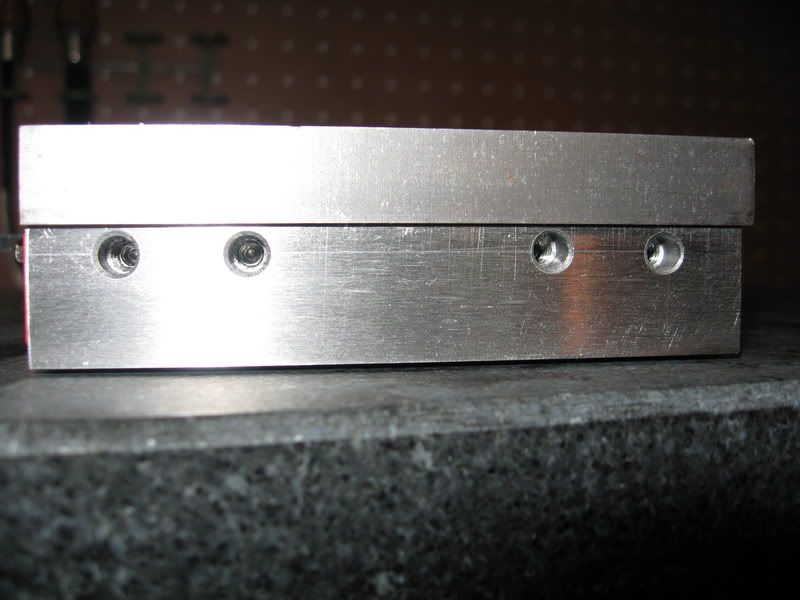

A few new pics. The rails are mounted and now have formed the lathe bed "ways". I have to disagree with Ian's thought's that the headstock should be mounted first. It is a very long time consuming job to mount the rails and have them run truly straight. To try and do that at the same time as aligning the headstock would be a monumental task of tail chasing. The slightest torque or twist with these 15mm rails can throw them off .0005". IMHO you need to first establish the bed ways by precisely setting the rails which is quite a task to do it to a very low tolerance.

I made a pusher block mounted to the carriage to act on the 2 linear blocks for the master rail. This will also increase rigidity. For the reference surface I tried using parallels and a long straight edge. But I was not satisfied with the method. Instead I setup the surface plate so it could be used as the reference straight edge to set the master rail.

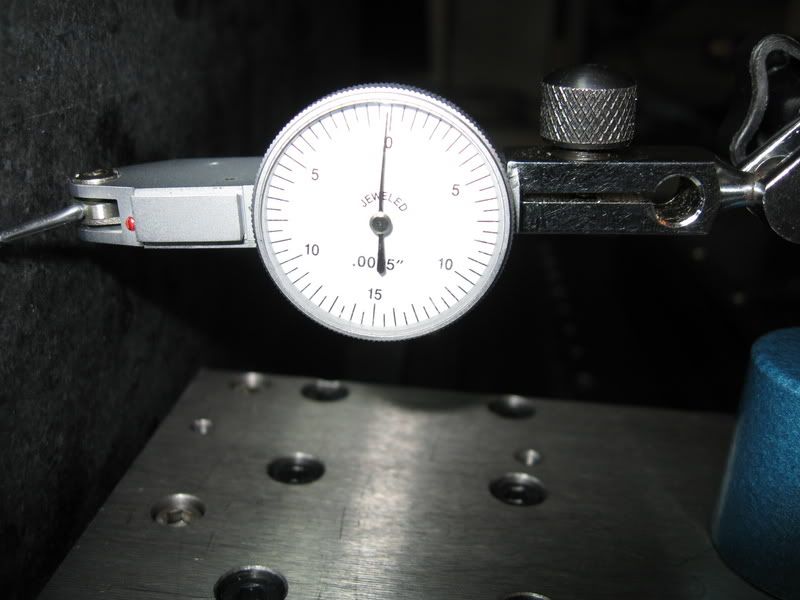

My max variance in carriage travel over 12" is ~.0002" but it's at ~.0001" for the first 10" away from the headstock. Now just how good the machine holds this tolerance will remain to be seen. But surfacing the rail risers made a big difference.

Headstock alignment is roughed in right now. I still need to make push/pull screws. With just tapping to set it I have it set at .0005" out 8" from the chuck. Vertical is out .001" 5" from the chuck rising upwards. That I will leave alone as the effect on cutting is so small it is not of any concern.

I found this concering vertical alingment on a lathe at the practical machinist site-

" A vertical movement of .005" of the cutter bit will have less effect on the turning diameter of the work than you may think. For example, lets say you are turning a piece of stock down to one inch (1.000"). You have the cutter bit set exactly on center with the work and it is cutting exactly at 1.00000" (at least, at the beginning of the cut as it moves towards the headstock). As the carriage assembly moves closer to the headstock, it passes over the worn section of the bed and the tip of the cutter drops .005" below the center line. By applying the Pythagorean Theorem, the diameter will increase to 1.00005". Of course, the error will be greater as the diameter of the work gets smaller because the ratio of the error to the diameter increases. For example, when turning a piece of stock down to .25000", the diameter will increase to .25020". Still, not too shabby."

I'm only at .001" 5" out from the chuck.

The last pic shows the carriage travel deviance from 0 at the end of the bed.

-

09-17-2007, 01:03 PM #3

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

-

09-17-2007, 02:04 PM #4

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Ian, sorry I misread your post.

I have to agree, that building a lathe that will be worth a dang is a very complex project. I had no idea how time consuming it would be just to get the rails lined up to the point where I can call them "precise". It took me 2 days of work to get them to this point. I have to wonder how many guys using linear rails actually have them setup nice and straight. It's been said one can not make a machine any better than the machines used to make it. I reasoned because I am using linear rails and not milling/grinding dovetail or sliding ways I could actually make a machine superior to what I have now. I still believe this but it is not a simple matter of buying some rails and bolting them down!

I have done a LOT of reading on lathe designs over at http://www.lathes.co.uk/index.html

I find it fascinating reading! I could not even imagine trying to make a manual lathe with change gears etc.

I have 3 more ball nuts ordered so I can finish the ballscrews and preload dual nuts, belt drive components for the cross slide and a proximity sensor for the spindle on the way.

Steve

-

09-15-2007, 10:42 AM #5

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Yeah, I thought he was a bit old too.

Hi SJ, as a matter of fact I would consider your project in the highest calibre.

There are so many things that can go out of wack, and it's a real pain to have to go back and change the design or something.

I would venture to say that although the design is unconventional, so was the Concorde, it will still do what you want it to as long as you just keep applying your logic, and reason each problem out.

This is how the best engineers work at it.

Even with a full set of working drawings, there's always something that gets overlooked and that's the fly in the ointment big time.

I defy anyone to make a design for a conventional centre lathe and not end up with some hiccup or unforseen hitch along the way, and that's when you consider that the lathe has been around for at least a century in it's present state of development before CNC.

Most of us are working with the aim to produce one only, whereas the lathe manufacturers have made prototypes and field tested them to get the production right, and what you finally buy has had it's forebears doing many trips back to base dragging bits that fell off, I think production race cars are like that.

That reminds me of the Great Panjandrum, dreamed up by some members of the officer class in the 2nd world war, to storm ahead of the troops when landing on the beaches to set off mines, well nigh annihilated the officer observer corps.

I can't wait to see the wheels go round.

Ian.

-

09-17-2007, 01:31 PM #6

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi SJH, nope, re post #91, I assumed the rails were already set-up and so could be used for a level surface and checking point.

What I meant was the headstock bottom must first be made level and true to the spindle centre line by using a test bar in the chuck and dialing it on the surface plate, after which it can be mounted on the prepared base and checked for allignment to the rails.

You're quite right about the above/below centre differences not making a 'haporth worth of difference, as long as you get the 150mm (6") out good to a thou' the rest will just go along for the ride.

Incidently, and just as a matter of interest, a turret lathe has the centre height very accurately alligned because they use a "knee tool" to produce parallel work on a repetition basis, and this tool cuts along the top of the work from the turret slide, and it is this function that allows work to be held to diam tolerances when the operator is pushing the production, but for your set-up the height allignment is not that critical, unless you are going to have tools in the turret that cut on the top of the bar.

I read back over the posts to get the background again, one of your best decisions was to get the surface plate.

I think if you had opened a thread with the proposal to build this lathe from a design concept without drawings, you would have got a million reasons why it could not be done without a whole heap of expensive gear, but it just goes to show you, if you get the show on the road and work round the design it will eventually fall into place.

Congratulations, can't wait to see the wheels go round.

Ian.

-

09-17-2007, 02:47 PM #7

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Steve, If you look at centre lathe design using raised Vees you will notice that only one slide way is the guiding way, the other, a flat slide, just carries the end of the carriage and prevents it from twisting around the X axis.

Using linear bearings and having two rigidly alligned bearing surfaces over the total length of the bed makes lining them up very difficult compared to common centre lathe practice.

However there are a number of lathes that have two Vee slides to carry the carriage, and to get the carriage to ride on them equally and evenly for the total length of the bed without binding is a piece of cake, due to the fact that the carriage can be fitted to the bed by scraping the two Vees on the saddle to fit the bed, as long as the bed is true.

This is of course impossible with linear bearing slide ways, as they are a pre assembled package and have to be set down and alligned to each other or binding will occur.

But they do run so very smooth and, if correctly set up, very precise and accurate.

I think that lathe design should be taken in consideration when doing a project like yours, but with the use of linear bearings, ball screws and stepper motors doing the moving, a different approach is needed to get the full benefit of this design method.

There is no way that you could think of that would make milling Vee slides a superior method for a CNC lathe, just too much friction to overcome when the slideways are adjusted to the minimum clearance.

Apart from that, you would have had to have a casting made, if the conventional method of lathe construction were to be followed, which means a large machining set-up, not even an option when you can buy a lathe that will out perform any home built lathe at half the cost.

Your CNC project is an exciting venture, and I wouldn'nt mind betting that you have hundreds of fans "tuning in" to get the latest results.

Ian.

-

09-17-2007, 02:54 PM #8

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

-

09-17-2007, 10:29 PM #9

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 284

Hi Steve

What is the purpose of the bar & adjustable parallel you have between your Linear Bearings? I see that you have a set of set screws pushing everything together. Thanks for the help and keep up the good work.

Willy

-

09-17-2007, 10:50 PM #10

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Willy, the parallels were just temporarily installed to test out the pusher block I made.

Steve

-

09-18-2007, 12:09 AM #11

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 284

Hi Steve

What is a pusher block?

Is the item behind the Spindle Housing that is belted to your Spindle an Encoder? What did you use for an Encoder?

I happen to have a 1-1/2 hp, 3 Phase Motor and Hitachi VFD that I was thinking of using for a CNC Lathe build similar to yours. I know it's over kill but I have the stuff and might as well use it. I was thinking of mounting the motor at the rear of the Spindle Housing and drive the Spindle with a couple of belts. I also have a couple sets of Linear Rails that I picked up for another project that never got used and would look good in a Lathe.

What are thoughts on using this Motor/VFD set up with the same Spindle you used?

I have learned so much from reading about your lathe project. Thanks for the help and keep up the good work.

Willy

-

09-18-2007, 03:13 AM #12

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Willy, there is no encoder or sensor in any of the pictures I posted. The rear of the spindle was marked with a white tape strip and I hooked up my tach to measure spindle speeds to verify my belting setup.

I will be using a proximity sensor to supply a index pulse to Mach3 for threading.

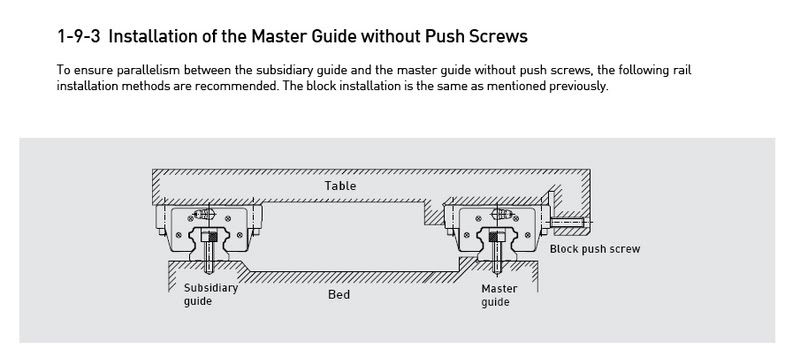

This detail is taken from the Hiwin installation guide. There are several different methods that can be used to mount the rails and blocks and they are all outlined in the manual.

I have a 1hp 3ph motor on my 250lb 9x20 and that is a lot of power for that light machine but I do still use the 6 speed belt drive.

I would probably run such a big motor with very little reduction on this small spindle. Should work fine if you mount it remote or in a fashion where the heft won't distort things.

Jesse, The mounting bolts for the rails are M4 x 16

Here are some links to tech specs for these rails and blocks-

http://www.automation4less.com/linhd3.htm

Bottom of the page download "hiwinguideway.pdf" 94 page catalog with specs and mounting and installation methods.

http://www.automation4less.com/linear.htm#pdfs

Steve

-

09-24-2007, 02:57 AM #13

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

yes, several improvements and updates. I doweled the linear rails to the risers for added rigidity, head stock adjustment push blocks done ,head stock tilt fixed, improved upon carraige movement to .0001" the entire rail length.

And I also took a wild tangent in my lathe obsession and purchased a very very rear and unusual lathe today.

It's an Artisan lathe made somewhere around the late 19teens- early 1920's

Condition is excellent! shows very little use. I'm very excited to have scored this machine!!

For pics of the lathe if interested go here- http://s109.photobucket.com/albums/n...ediafilter=all

And for indepth info on this machine- http://www.lathes.co.uk/artisan/

Mine seems to be a early version of the fully developed machine in the article.

But not to worry, the cnc bench lathe project will be finished before I begin to go through the old Artisan.

Steve

-

09-29-2007, 11:28 PM #14

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Ian,

Well the old machines have some real character that's for sure. After I finish up the cnc mini lathe I'll turn my attention to the Artisan as this machine is a thing of beauty and it's condition is better than excellent.

But that's probably for another forum.

Worked on the cnc lathe project today. Headstock aligned, cross slide aligned,

crossfeed dual preloaded nut and stepper belt drive done. Very smooth and very rigid setup IMHO.

Backlash should be under .0005" on the crossfeed. Won't know for sure until it's running.

I have not taken any pics yet. A lot of this work is careful setup and alignment details that just eat up the time.

Steve

-

09-30-2007, 11:30 PM #15

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Very close to making some trial runs

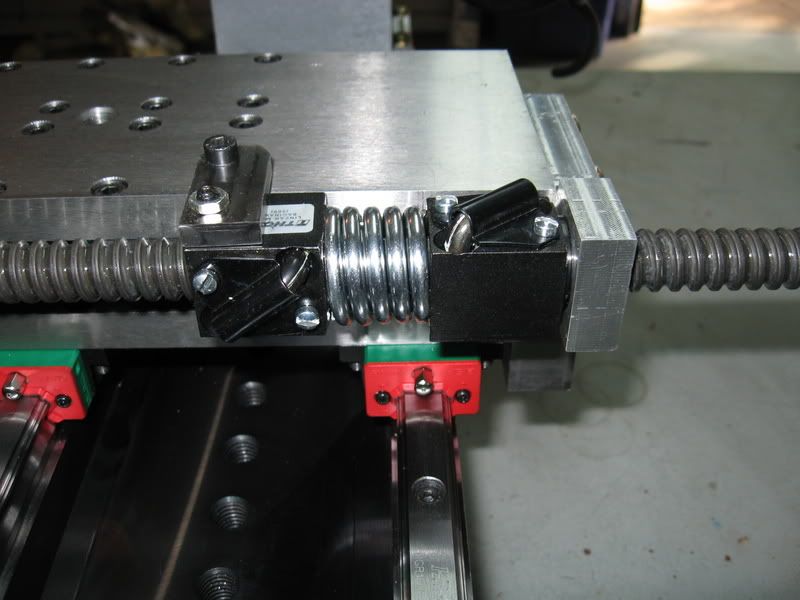

Current status pics. Dual spring loaded nuts in each axis. Both nuts adjustable for anti rotation. Simplified the motor drive to direct to spindle after testing the old setup.

I could test it out cut metal with it right now but will wait until the spindle index sensor and limit switches are installed. Tailstock will be after that.

Steve

-

10-01-2007, 03:19 AM #16

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 284

Looking good Steve. Why the change on your Spindle Drive? Just simpler?

Can't wait to see some Videos of it cutting metal. Good job.

Willy

-

10-02-2007, 01:06 AM #17

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Willy,

yeah the old belt drive just did not do it for me the more I looked at it.

So for now just a simple direct drive for starters.

Steve

-

10-03-2007, 08:35 PM #18

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

First tests of the x and z axis under cnc power-

http://s109.photobucket.com/albums/n...lathetest1.flv

It's a short clip running some g-code for a facing cut.

Backlash is just fantastic. I can't even measure it with a .001" dial indicator. I can command a .0005" move and then back to zero and on the .001" DI it looks great.

Steve

-

10-03-2007, 09:58 PM #19

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 284

Looks Good.

Hi Steve

Looks good. Can't wait to see it cut some metal. It's going to do a fantastic job.

What was your reason for belt driving the cross slide? To get away from having the Stepper motor sticking out in front?

Any guess on the maximum machining and jog rates?

Keep up the good work.

Willy

-

10-04-2007, 12:50 AM #20

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Willy, yes the belt drive is more compact than direct drive. I saved about 4" of overhang. I did the same type of setup on my x3 mill. Y axis belt driven and x axis direct. I am using 3mm GT2 belting. Extememly low backlash.

As far as machining rates, I don't know yet. I owned a 7x10 lathe for a few years and know what it was capable of. This machine should be able to easily handle more than a 7x.

The machine can rapid much to fast for it's own good. With only 4" of crossfeed travel you have to be real careful.

It will easily rapid at well over 200IPM but that's silly. I set it at a nice controllable 75IPM for each axis.

I am floored by the backlash though. It makes my x3 mill look lousy. I'm using a pretty hefty spring preload amount between the nuts but the reason backlash is so low IMHO is the very very low stiction on the linear rails.

I know backlash is not as big a deal on a lathe. But linear rails and ballscrews can't have slop or it will be very prone to chatter.

I'm cautiously optimistic right now that I have covered all the bases and very little tweaking is going to be needed.

Steve

Similar Threads

-

80/20 benchtop lathe build

By LeeWay in forum Vertical Mill, Lathe Project LogReplies: 87Last Post: 06-15-2015, 01:35 AM -

DIY benchtop mill build

By mkuivamaki in forum Benchtop MachinesReplies: 36Last Post: 03-19-2014, 08:54 AM -

Looking to build my own benchtop cnc!

By rim basses in forum Benchtop MachinesReplies: 0Last Post: 10-09-2009, 07:20 PM -

Not a Benchtop mill but Dang! You have to see this build.

By praetor in forum Benchtop MachinesReplies: 19Last Post: 05-19-2009, 10:58 AM

Reply With Quote

Reply With Quote