Thread: CarveOne's Steel Channel Rebuild

Results 1,581 to 1,600 of 3151

-

08-06-2012, 02:39 AM #1581

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

CarveOne

http://www.carveonecncwoodcraft.com

-

08-06-2012, 02:56 AM #1582

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

I will take some if it does not turn out to be fire wood...:stickpoke

Louhttp://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

-

08-06-2012, 10:47 AM #1583

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

We all have one of those once in a while. The guys who make very fancy commercial signs spend weeks on them sometimes and it can get really expensive to have to remake one. That's what the flag display box I'm working on is all about. This time it is even more complicated with more chances to mess it up again. If this one turns into firewood, it's pretty firewood, and I put it on the display wall as a "reminder".

If you want something low cost to do with Vcarve Pro, Google "Maze puzzles" and find a maze you like, save the image, convert it to vectors, and Vcarve it in MDF. Good gifts for the young kids in your family. There are lots of sites that let you print the puzzles for kids to play with. Those can be scanned and converted to vectors. Size the vectors to fit available scrap MDF pieces. The mazes run from simple ones to fairly complex ones.CarveOne

http://www.carveonecncwoodcraft.com

-

08-06-2012, 02:22 PM #1584

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

-

08-06-2012, 06:08 PM #1585

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

I have cut a little aluminum to see how well the big machine can do it, but haven't tried it on the smaller steel machine yet. I have cut considerable 3mm carbon plate for Jeff Foley to be used in his wind tunnel model jobs. I used a 1/16" solid carbide cutter that was in Grizzly Industrial's box of assorted carbide cutters. Later on I got the equivalent type from Precise Bits. As I recall, I used 0.032" (~50% diameter) step-down, 15 ipm plunge rate, and 50 to 60 ipm feedrate and got pretty good results.

Don't cut it without a good dust collection shoe and vacuum, and use a suitable dust mask.CarveOne

http://www.carveonecncwoodcraft.com

-

08-06-2012, 07:26 PM #1586

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

-

08-06-2012, 07:30 PM #1587

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

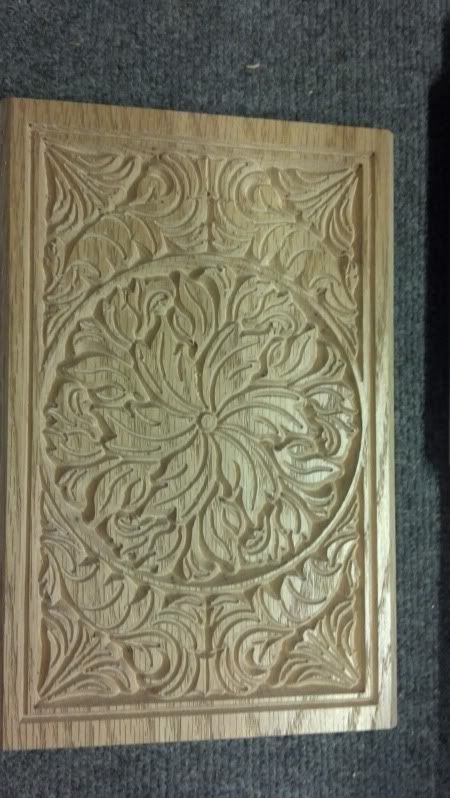

Here is a picture of the top to the Paradise box Red Oak I took the pic with my Driod Razor..

[ http://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

http://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

-

08-06-2012, 07:52 PM #1588

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

Everything is going well so far today. Keeping fingers crossed. Need to make the Purple Heart inlay pieces (from purple heart wood) and glue them in place next.

The oak pieces that are double side taped together are not glued together by the poly paint, so it will be easy to slide polyethylene sheet triangles into the joints to keep epoxy from getting to the wrong places. It may still be a bit tricky to pry the glued frame halves apart when fully cured.

Need to cut the triangular Lexan panels so they can be installed during the glue-up.

This is probably the most complicated thing I have attempted so far. Building the big CNC machine seemed to be easier. Before glue-up there needs to be new text added to the front edge of the bottom piece. I don't know what it says yet, so after today this project goes on hold for a week or two.

CarveOne

Before glue-up there needs to be new text added to the front edge of the bottom piece. I don't know what it says yet, so after today this project goes on hold for a week or two.

CarveOne

http://www.carveonecncwoodcraft.com

-

08-06-2012, 09:28 PM #1589

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

That looks plenty good to me Lou. Are you going to carve anything into the side panels, or leave them plain on the outside per the original project? Doing double side is tricky but not difficult. It just requires some planing ahead and using a simple fixture.

CarveOne

http://www.carveonecncwoodcraft.com

-

08-07-2012, 01:11 AM #1590

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

Thanks C1 I am going to build per the plans in the Vetric news letter but with your staining or finishing technique I am building it for my wife and that is the way she wants it. I showed her some of your designs she really likes them but she likes this best. She likes things simple I like your Aztec calendar one best..

Doing double side?

Louhttp://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

-

08-07-2012, 01:14 AM #1591

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

-

08-07-2012, 03:09 AM #1592

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

I finished cutting and fitting the inlays and will split them in half tomorrow using the new Delta 20" scroll saw. The cuts must be dead center of the hinge line and as thin as possible so that they fit against each other properly when the box halves are closed.

I now know what the new text is to be, and where to put it, so that will be done tomorrow. The Lexan still needs to be cut to size. I hope to have the glue joints curing by sometime late tomorrow afternoon.

The purple heart pieces are brownish now, but will be more purple color in it by tomorrow morning. When poly is sprayed on it will get even more purple. There is a little bit of shiny curl in the wood also.CarveOne

http://www.carveonecncwoodcraft.com

-

08-08-2012, 02:01 AM #1593

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

A number of interruptions today prevented me from doing anything with this project until evening. I managed to carve the last edge of the frame with the presentation text. The parts are taped together temporarily with green masking tape for the photos.

CarveOne

http://www.carveonecncwoodcraft.com

-

08-08-2012, 02:17 AM #1594

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 118

C1, that is turning out very nice. Your work is great as always. One question about the purple heart. Why didn't you offset the ribbon just like the heart or completely fill in the ribbon area?

Love the way the puple heart looks inset with the lex.

I have the flag from my Grandfather (WWII vet) and my step father (vietnam vet) and your project has given me some new ideas. Thanks and keep up the great work.

chuck

-

08-08-2012, 02:07 PM #1595

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

When I made the first one I found an image that I used to make a simple representation of the medal. I was under a lot of time pressure to get it done in less than a week before the July 4th events at the county fairground, where this was to be presented after my skydiver friend made a jump as part of the show during late afternoon. I didn't spend a lot of time on the medals and "Skydiver Guy" as I refer to him liked it, so I didn't change it this time. I messed the first attempt at the last hour or two before the time I had to deliver it. Mr. Stokes has seen the original, and I told him the replacement would be better.

It would be nice to model the whole medal including the portrait. A simple representation was all I was asked to do though. This one might look better if the stripes were painted white, and the frame around the heart painted gold.CarveOne

http://www.carveonecncwoodcraft.com

-

08-08-2012, 03:41 PM #1596

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

C1, It looks great I like the inlay nice work..

Louhttp://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

-

08-08-2012, 06:34 PM #1597

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

Thanks Lou. I used the vector offset tool to make a separate file that has a 0.006" smaller set of inlay parts. I cut a slice of purple heart wood to about 1/4" thick on the band saw, then created a surface plane file to flatten the wood to about 3/16" thick. The pockets in the oak frame are 1/8" deep, but could have been 1/16". Thicker pieces don't break as easily while working with them. The edges of the inlays were rounded a little by hand with sandpaper. Really easy to make the inlays this way.

CarveOne

http://www.carveonecncwoodcraft.com

-

08-08-2012, 06:44 PM #1598

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

-

08-08-2012, 06:55 PM #1599

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

CarveOne

http://www.carveonecncwoodcraft.com

-

08-08-2012, 07:57 PM #1600

Member

Member

- Join Date

- Sep 2011

- Posts

- 1183

C1, I will have to try it out there are some things in VP I have not tried yet like tile feature. Well I have the box cut I will stain it next and have some pictures up once I have them stained. C1 which other designs that you have shown are the ones that can be carved with VP?

Louhttp://www.cnczone.com/forums/diy-cnc-router-table-machines/140832-cnc-software.html

Similar Threads

-

CRP2448 Rebuild: Welded Steel Base and Rackmount Electronics

By Gerald V.B. in forum CNC Wood Router Project LogReplies: 7Last Post: 02-17-2013, 08:12 AM -

Moving Table Steel & Concrete Rebuild

By JohnZ in forum CNC Wood Router Project LogReplies: 21Last Post: 07-04-2012, 09:55 PM -

encoder wiring channel A and channel B

By senor J. in forum Gecko DrivesReplies: 3Last Post: 12-13-2011, 04:30 PM -

Steel C-channel Build - Questions and pictures

By olskool in forum DIY CNC Router Table MachinesReplies: 10Last Post: 07-07-2007, 07:31 AM -

IRC channel for EMC

By Dan Falck in forum LinuxCNC (formerly EMC2)Replies: 0Last Post: 12-18-2004, 06:03 PM

Reply With Quote

Reply With Quote