Hi matt, Thank you. actually we do have some progress on the SVM-2 ATC recently becuase we have been waiting parts for SVM-0...SIGH...

Here are some pictures during the SVM-2 ATC prototype building process.

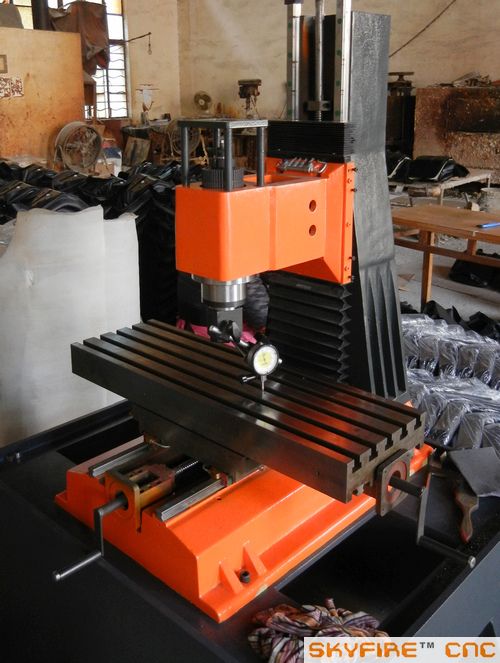

If I'm correct, I should upload the progress from the SVM-2 body painted..

And then moved on to the super heavy base with a simple swarf removing structure.. It's an easy design. (must declare that this one is a special stand for customer. The formal stand with commercial SVM-2 will be a developed one with coolant system and swarf drawer inside)

And then installed our BT30 spindle unit and adjusted the perpendicularity to worktable.

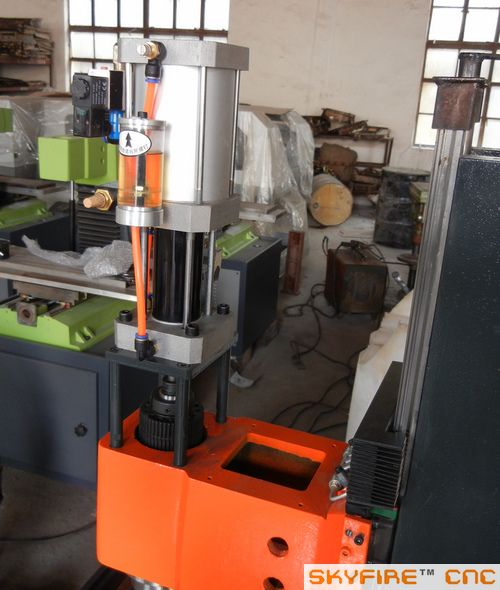

And then the aire cylinder system.

Welding the ATC bracket.. the steel boards were cut with CNC laser so it will be accurate.

ok.. try to install and locating the ATC

powder cotated ATC bracket. and rail covers, gas spring installed.

some details of the ATC and spindle unit.

almost forget the big AC SERVO spindle motor system.. the AC mtor is so big so I will need to design a bracket to put it on to the head..

This is the SVM-2 ATC progress so far.. will update next progress later. Next progress will be mostly the electric system and controlling system connection and tests. And enclosures...It's another big part to do:tired:

Try here

Results 1,641 to 1,660 of 3662

-

04-19-2015, 01:07 PM #1641

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 91

-

04-19-2015, 01:54 PM #1642

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Re: Show how to build a CNC machine from the very beginning to the end

Ian, I think the other problem with a drop in rack is you won't be able to use a facemill or such tools where the diameter exceeds the that of the tool holder. Also with the carousel type it's easier to set up because the tool will always be in the same location, no x-y moves to go to different tools.

I suppose though, for smaller jobs

jobs, it could be good if it didn't interfere. But then you'd have to remove it for larger jobs (or to use a tailstock with a rotary) and have to recalibrate it when reinstalled.

BTW the Levil is not like a traveling column mill... It IS a traveling column mill. Incidentally with a larger work area... The pricing is pretty far up there, you can buy a good use VMC for that price!

-

04-19-2015, 06:01 PM #1643

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Re: Show how to build a CNC machine from the very beginning to the end

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-19-2015, 06:07 PM #1644

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Re: Show how to build a CNC machine from the very beginning to the end

Yep....about 30 grand I believe.....very exotic, looks cute though, not really my cup of tea for hobby fun stuff.

The ATC for the SVM-0 is just a thought that it might be handy......the design I mentioned has the tool pallet on an off centre pivot that is either on the work area or swings 180 deg totally off the end by way of a stepper motor, so impinging on the work space is a problem that wouldn't occur......a bit of XY'ing would access all the tools I think.....have to see when the mill arrives........one look will tell volumes.

There's always a way, just depends on how badly you need it.

LOL.......Big diam facing mills, I don't think so, they're not an option for the SVM-0.....a fly cutter maybe for finishing off a large face area......it might handle a 50mm diam 5 tip facing cutter, but at very small depth of cuts, so that's a waste of time anyway........ and a fly cutter would cover more area anyway.

For those occasions when the flycutter is needed, I expect the program could be juggled to allow a manual QCT op to occur.

Hey..... even QCT was not on the cards until the head casting was split to allow different spindles to be fitted.....when that occurred the whole situation changed.......ATC is the next follow on possibility, if/when whenever.

As I see it, a short plate could be bolted to the end of the table Tee slots to carry the off centre pivot for the pallet, and that would only takes a few CM's of the table end etc.....early days yet.

I think any 4th axis work can be handled with the high speed spindle, certainly for carving chess pieces etc, so no tool changer needed.

Ian.

-

04-19-2015, 06:40 PM #1645

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Re: Show how to build a CNC machine from the very beginning to the end

Thank you Louie and all of you guys. I will do better and better as my facility growing and gets strongger. I hope to become the best small CNC manufacturer in China even if I'm not the biggest.

Very appreciate your guy's concern and support at the beginning. This thread will be the best memo for all of them.

Very appreciate your guy's concern and support at the beginning. This thread will be the best memo for all of them.

I noticed now we begin to talk about ATC..I agree that the carousel type with 8-12 tool capacity will be some best best choice for small CNCs. As showed before it works well on SVM-1/2 and I'm sure it will work too on SVM-0 with ISO20 tools. The industrial carousel ATC available from market is still some expensive now. I'm learning it and want to get my own ATC design in near future to drop the cost for users. I think I may use some servo motor to rotate the carousel and locate the tools with absolute value encoder or something like that. It will make the ATC rotary device clean and easy. the bracket and the air actor is a simple thing. Another important thing may be the electric part of carousel servo controlling and interface to CNC controller. PLC will do that but I may want to do it with a simple MCU. This is my initial thinking about a self made ATC in future..For current industrial users, I still commend BT30+ bamboo hat ATC

And it seems that the new fashion way of the ATC is this:

I can see more and more CNCs begin to use this design that had been mostly used for drill and tapping CNCs. This type is more efficient that bamboo hat type but machine head structure get complex and much more weight to carry this ATC and all tools together.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-19-2015, 07:07 PM #1646

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Re: Show how to build a CNC machine from the very beginning to the end

Hi Ian, see your words about fly cutter,, that's what I did on SVM castings..lol

QTC is no problem for SVM-0 even the spindle has been changed and then changed back.. the offset of the tools didn't change. Only the machine zero position changed. It's not acceptable to ATC, but QTC is fine with that.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

04-19-2015, 10:59 PM #1647

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

04-19-2015, 11:06 PM #1648

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 264

-

04-19-2015, 11:09 PM #1649

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

QCT was a possibility with the R8 spindle as well. And Imnot talking about huge endmills, just those whose diameter is larger than the holes in your rack design. Plus the tools are in the vicinity of swarf and coolant which might prevent proper seating in the spindle bore. The carousel is far enough away from that stuff. In the Wabeco design a lid retracts and opens to protect the tools. On a larger machine like a Datron as well.

-

04-19-2015, 11:10 PM #1650

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 264

Re: Show how to build a CNC machine from the very beginning to the end

The arm system used for the novakon ATC is an intersting way to explore it's more fast than traditional carousel type as tormach do and less heavy too

-

04-19-2015, 11:29 PM #1651

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 264

Re: Show how to build a CNC machine from the very beginning to the end

Attachment 277318

A complex magazine type but the more user friendly to me but only possible with this kind of head axis motion , I love this integrex from Mazak

-

04-20-2015, 03:20 AM #1652

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Re: Show how to build a CNC machine from the very beginning to the end

Hi.....all those solutions are fine and no doubt carve lots of time out of a work day , but for me, a simple magazine solution is probably the easiest to make and not get into rocket science for the controls.

The magazine type is my first preference because it requires only X and Y moves to position the head for the reqd tool, and some Z to enable it.

Anything that requires swing arms and rotating carousels starts to get complicated.

BTW, back in 1974 we had a Burgomaster turret head drill that had a turret with 6 tools on it.......this was not CNC, being a manual machine, but the principle of one motor and spindles that indexed round to the drive position when needed was the same as that mill in the previous posts......nothing new under the Sun, but different applications.

The thing I like most about the SVM-0 mill, is it's utter simplicity......that is to say, it's definitely state of the art in concept and not amateurish in simplicity, but well designed purpose built to do a specific job right from the word go.........adding complexity is a counterproductive step ....in any direction.......so I will always plump for the simplistic approach.

I doubt whether the ATC will be a much needed item, but could be a solution if the need arises.......whenever.

To produce one for the market to suit the SVM-0 size mill and down to a cost would entail quite a lot of R&D, and if the users of this mill aren't in that market the cost would not be recoverable.

You can scale anything down to suit the machine, but the inventory needs volume sales to be a saleable item.

Ian.

-

04-20-2015, 03:35 AM #1653

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Re: Show how to build a CNC machine from the very beginning to the end

Yes, swarf and coolant inclusions would be a problem that would have to be paramount to the design, or else you get lots of wobbly tools etc....LOL.

Even the UMC-10 has a puff of air to ensure the tools are clean when the carousel delivers them.

On the Levil WL- 400 they have a plexiglass fence to stop swarf and coolant getting to the tooling shanks in the magazine.......still could be a problem for leave alone machining with ATC's if just one itty bitty piece of swarf got to the tools.

One other Bridge type mill, The Toolcrafter , has the magazine on the end of the table with a hinged cover.....same design as I'm thinking of, but the cover keeps the tools clean.

Ian.

-

04-20-2015, 03:37 AM #1654

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 889

Re: Show how to build a CNC machine from the very beginning to the end

Your kidding me, With all the options you've added, it no longer is.The thing I like most about the SVM-0 mill, is it's utter simplicity.

Defeng, you've been MIA for a year. But looking at those pictures of the bigger mill you've been working on( a few post ahead of this one,#1626 to be exact, what are all those little green machines in the background? Seems lot's has been going on. Same for that extended table. It just doesn't turn up magically overnight. Somethings fishy here and I think your only telling us what we want to hear.

What the real story? Did you ship Lou's mill yet?

Now because I'll probably criticized for stating the obvious, I'll refrain from posting on this thread anymore.

Good luck with your venture.

-

04-20-2015, 04:00 AM #1655

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

04-20-2015, 04:15 AM #1656

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Re: Show how to build a CNC machine from the very beginning to the end

Ian, Ian, Ian... Can of worms warning again...

You proposed pivoting a matrix type magazine. That's even more complicated since the control of that pivot has to be precise, and there's no avoiding having that magazine have ro land right in the work envelope of the machine, thus moving it away does no good since you need dead space just to allow for the magazine to swing in within the work envelope.

A carousel type ATC is really as simple as it gets and requires absolutely no x - y positioning. It requires no table real estate. And it's actually easier to program.

-

04-20-2015, 04:38 AM #1657

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Now you really don't seem to have a clue... In the Brother design, the tool is unloaded as the z retracts, and a new tool inserted as the z goes back down... in one motion... while th x -y is repositioning. The whole process, cut to cut takes 1.2 SECONDS. This is Totally different from a turret on a lathe, as those tools are fixed.

NOTE a carousel ATC needs no swing arm, just a cheap actuator to move it left and right. The actual mount is STATIONARY. Hoss actually has a swing arm in his design but it's not necessary.

I think even with a stepper an 8 tool carousel would easily work. A simple Geneva mechanism could even provide precise positioning of the carousel.

I have to agree with G59, as you are taking the simplest of things and attempt to complicate them.

-

04-20-2015, 05:45 AM #1658

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Re: Show how to build a CNC machine from the very beginning to the end

Hi.....a lot depends on who's going to make something......first you have to design it with the making in mind.......carousels are not what I would call simple, but we'll just have to see what transpires, if at all.

BTW, Louie, the swing around pallet would be above the table just like the carousel type....it doesn't have to be actually down on the table, so it would be above any work piece that was on the table end when it swung around and clear when it swung back......it moves with the table so work cannot bump into it when at extreme left......all academic and trivial detail really.

To answer G59's dull comment re the simple design and all the options added that seem to make it complicated........the basic mill, now with the split head casting as a standard design feature, has simplified the whole mill design in that it can accept whatever spindle you desire from ANY of those available, and any you want to have custom made.......that is pure genius........NO OTHER CNC MILL IN THIS CLASS HAS THIS CAPABILITY..........none......and we are talking about the SVM-0 mill, not something allied to the size of it's big brothers......and even in that category, you still don't have the options afore mentioned.

Didn't I say previously that you could also have an EDM head, a 3D print head fitted etc etc.....if you really wanted one.

If you look at the design, it is state of the art......linear rails all round.......... ball screws all round......high speed spindle.....2 speed milling spindle with QCT capability, just for starters.

I did say simple......but G59 has mistaken simple for cheap and confused increased cost factors for extended options as complications.......just pay the money, nothing complicated about that.

If you really want to get into complication, try retrofitting a manual mill and attempt to have it as a CNC fully capable machine, that is after you remove almost half of the machine's parts to make it tick as a CNC.....that is by no means a plug and play after market option as the suppliers never considered anyone to have a CNC capability for a purely manual mill.

Ian.

-

04-20-2015, 05:56 AM #1659

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Re: Show how to build a CNC machine from the very beginning to the end

BTW.................IF......an ATC was considered as a must have item by enough customers.....no doubt Defeng could design one that would suffice, or just add another 100mm to the table length and travel and fit the static magazine as I suggested.

Ian.

-

04-20-2015, 06:07 AM #1660

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Re: Show how to build a CNC machine from the very beginning to the end

Well Ian, I'll leave it to you to figure out the programming for your magazine matrix. It's not as simple as you think. I know you can elevate your toolholder design, you just never mentioned it till now. Also you were so worried about the dynamics of the Z axis saddled with extra weight... Guess what, the same thing happens with the X and Y as well.

Yoy can't possibly talk about simplicity with one breath, then concoct complicated mechanisms and accessories in another. We all know what the components of the machine are, it's not helping the cause by repeating them ad nauseum.

There are many mill conversions out there. They're not always ideal, but these people DID IT, not blabbered about nonsense, and actually MAKE PARTS, not theorize about parts they'll never make. They actually know how to program their machines. We can have a conversation about this machine and its present and future options without dogging others that actually do work on their machines.

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM