My table is 3.5 meters by 2.5 meters. What kind of accuracy in linear systems do I need? I mean it is a plasma not a mill, so i only want to cut out stuff that is accurate to say .25 to .50 of a millimeter. So do I have to spend big money on thompsons, the igus system or even the dual l vee system.???

I see that the TORCHMATE uses just a piece of 3" by 1/4" flat whith bearings mounted on that. Is this all that I need? I mean it has to be accurate to cut out parts and weld them together without big gaps.

That way seems to me as the cheapest option. And I think that it might just do the job. What are everyone's thoughts.

Peter,

Results 1 to 8 of 8

-

02-21-2005, 11:38 AM #1

Erfahrener Benutzer

Erfahrener Benutzer

- Join Date

- Feb 2004

- Posts

- 427

What rail and bearing system to use for plasma table?

-

02-22-2005, 05:07 AM #2

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 601

My cousin builds and retrofits plasma tables. He swears by elevator rails for the gantry. The nice thing about them is they have all of the jack screws in them to get the gantry perfectly level and square. The problem is they don't have the profile to put bearings on to prevent lifting the gantry, which is no problem if you only plan to do plasma or oxy\fuel cutting.

-

02-22-2005, 06:31 AM #3

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

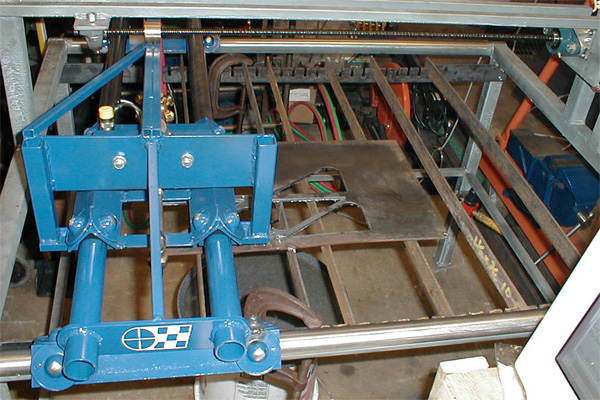

Almost anything will work. I used ball transfers, mounted in angle, riding on tube. I can maintain a couple of thou, plate shift and distortion is a bigger factor than the accuracy of my homebrew slides. A pic of my machine is here:

Certainly better than my old method (hand torch and grind). MIKE

Certainly better than my old method (hand torch and grind). MIKE

-

02-22-2005, 11:48 AM #4

Erfahrener Benutzer

Erfahrener Benutzer

- Join Date

- Feb 2004

- Posts

- 427

Accuratemike how much do ball transfers cost each?

How much do those ball transfers cost each? They have a thread on the end of them don't they, so that you can thread onto the angle iron?

Does the gantry slide along easily, can you just push it with your finger?

What kind of pipe are you running the balls on? mild or stainless. Is the pipe straight enough for you? My table is 3.5m long, will pipe be straight enough?

Also what thickness is the wall of your pipe?

Peter

-

02-22-2005, 11:02 PM #5

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

How much do those ball transfers cost each?

$4-5 each

They have a thread on the end of them don't they, so that you can thread onto the angle iron?

No. They had 2 mounting holes each. After drilling a few, I spot welded.

Does the gantry slide along easily, can you just push it with your finger?

Yes. They have 80 balls around a 3/4" ball. There is an oil hole in each. I blow this out with air and fill with light oil. Pretty smooth.

What kind of pipe are you running the balls on? mild or stainless. Is the pipe straight enough for you? Also what thickness is the wall of your pipe?

1 1/2" .125" Wall ERW 1018 steel. I picked through a bunch of randoms (I have this tube in stock for chassis stuff) to find the straightest four 4' pieces. You can see the tracks the balls leave on the rails. I can see the pressure increases on the outside sets of balls around mid-travel of the X. I would guess that the tubes "bow out" a teeny bit in the middle. I could probably tug them together a bit, but it hasn't mattered at all. The Y is very parallel.

It would work with outer balls only. Or on angle instead of tube. Or with bearings instead of balls. My point is, that it is not as critical as some may think. My gantry is ~55#, I can get it going 90ipm on 187 oz NEMA 23's, rolls very easily and in a straight line. Good luck, MIKE

-

02-25-2005, 12:22 PM #6

Erfahrener Benutzer

Erfahrener Benutzer

- Join Date

- Feb 2004

- Posts

- 427

How good will this linear bearing setup work

I went to the bearing shop this afternoon and I am planning on using 22mm OD by 7mm width with a 8mm ID bearings. These are rated to hold 100kg each, more than enough for my needs. They are $4.38 + g.s.t., so under $5 each.

I was thinking of having a rail of just mild steel, aluminium would wear to quickly, yes? I would use a flat of say 10mm by 50mm-75mm in width. I will put 2 bearings on the inside of each rail on both sides so that they stop twisting movement and also hold the trucks on. There will be 2 bearings running on the 10mm edge of each rail to take the weight of the gantry.

All up each truck will have 4 bearings each, 4 insiders and 4 on topers.

How good will this work?

-

05-22-2005, 05:48 AM #7

Registered

Registered

- Join Date

- May 2005

- Posts

- 1

hi, wich software are you working with?

-

05-22-2005, 05:57 AM #8

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

I use AutoCad, FlashCut & TurboCNC. Draw in AutoCad (export .dxf), convert to g-code in FlashCut (import .dxf) and TCNC runs the machine. I have to do a litlle manual coding in there (usually in NotePad) for pauses & lead-ins etc. MIKE

Similar Threads

-

Thomson rail and bearing question

By Darren in forum DIY CNC Router Table MachinesReplies: 8Last Post: 12-11-2003, 01:35 AM

Reply With Quote

Reply With Quote