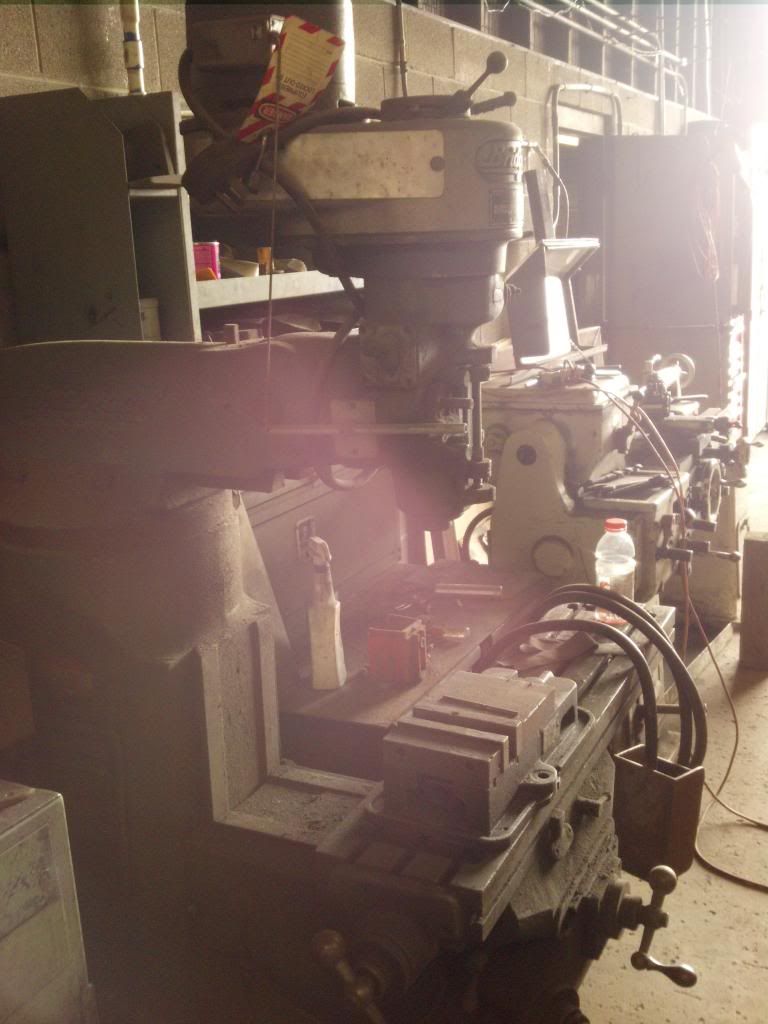

A friend of mine works at a welding shop owned by his father here in town, they have an old bridgeport in the shop, "taking up room." Everything moves freely, its covered in a thick layer of dust, its missing a few knobs, and it has a 3/4 hp motor wired for 220v single phase. Im told it works, didnt get to power it up while I was there, but I will be able to before purchasing.

The only information i have for age, is that my friend said he remembers his dad saying that this mill was purchased off the USS North Carolina when they were doing some restoration work. I dont know if that is true, or not, take with a grain of salt.

I would just love an estimate of what the lowest and highest price could potentially be for this mill. Highest assuming it is in perfect running order, and lowest in needing repairs.

Im also told he will include all extra tooling that he has since he has 2 of these mills.

The intended use is for light duty use in steel and aluminum in my garage.

I learned how to use a vertical mill in school about 7 years ago, so its been awhile since I have used one. I still have to look up what to check for when purchasing one. I am going to google that, but any insight on specifics would be greatly helpful.

Pictures:

Results 1 to 10 of 10

-

09-15-2013, 12:00 AM #1

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 8

Potentially buying a Mill, possible price range for this mill.

-

09-15-2013, 01:08 AM #2

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

jaballard86

$600 as it is, $800 max, it's missing parts on the end of the X axes, it should look the same as the other end, if this is how they take care of a machine like this, then don't expect the tooling to be much goodMactec54

-

09-15-2013, 01:08 AM #3

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 6028

Looks like its missing more than just the handle. 300-500 tops for that one IMO.

-

09-15-2013, 04:36 PM #4

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 8

-

09-15-2013, 06:01 PM #5

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

jballard86

The quill handle is not mounted on the head, but they are removable, so could be near by, the whole x axes, end is missing, this is the support bearing housing Handle dial Etc, everything else looks, normal, take a look at the chrome on the Knee, If this is in good shape, then you may have a gem under the dust/dirtMactec54

-

09-15-2013, 06:16 PM #6

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 6028

Dial is missing on the x, handle is missing, who knows if the support bearings are still there in the x. The dial and locknut assembly are not cheap unless you can find them used.

-

09-18-2013, 01:56 AM #7

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 8

well im picking it up on thursday, Im getting the mill, the vice, many collets, end mills, (he said everything he has extra of or doesnt want) he is going to load it on my trailer.

All for 600 I hope it ends up well.

-

10-01-2013, 04:26 PM #8

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 8

Here are a few updates if anyone wants to know:

The machine is at home in my garage, and is clean from the ways on the knee up, except for screws (maybe later.)

Starts up and runs fine.

Measured the runout from inside the mouth of the spindle with a dial indicator and showed less than .001 runout, tested on a unknown r8 endmill holder and showed the same.

Checked the deviation of the x axis showed a .001 difference from one side to the other.

Personally these numbers seam good, especially for a machine made in 1941, but I am lead to believe that for 40+ years of its life it was barely used, and in the past 5-10 years it hasnt been used.

What else should I look at/measure on this machine?

-

10-01-2013, 04:52 PM #9

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

jballard86

As I said there is sometimes a gem under the dirt & dust

There is not much else to check, the tram of the head/spindle to the table is adjustable, so this is the only other part to do, you should be able to get it down to .0005, in the X & Y axes, the spindle you could lap it to get that a little better than the .001, check in the taper of the spindle, with your indicator, is the spindle collet key still in placeMactec54

-

10-01-2013, 04:59 PM #10

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 8

The head is way out of tram, since ive moved it all around while cleaning. The collet key is not in place, I still need to order it.

Similar Threads

-

Suggested kit or commercial CNC mill in the $2.5k to $4k range?

By tomkinsc in forum Commercial CNC Wood RoutersReplies: 4Last Post: 07-31-2012, 10:18 PM -

Suggested kit or commercial CNC mill in the $2.5k to $4k range?

By tomkinsc in forum DIY CNC Router Table MachinesReplies: 2Last Post: 07-31-2012, 02:21 PM -

2004 VF1 price range?

By l u k e in forum Haas MillsReplies: 119Last Post: 06-29-2010, 06:48 PM -

CNC 35,000 to 50,000 price range

By deathbot3000 in forum Commercial CNC Wood RoutersReplies: 16Last Post: 11-15-2006, 08:14 PM

Reply With Quote

Reply With Quote