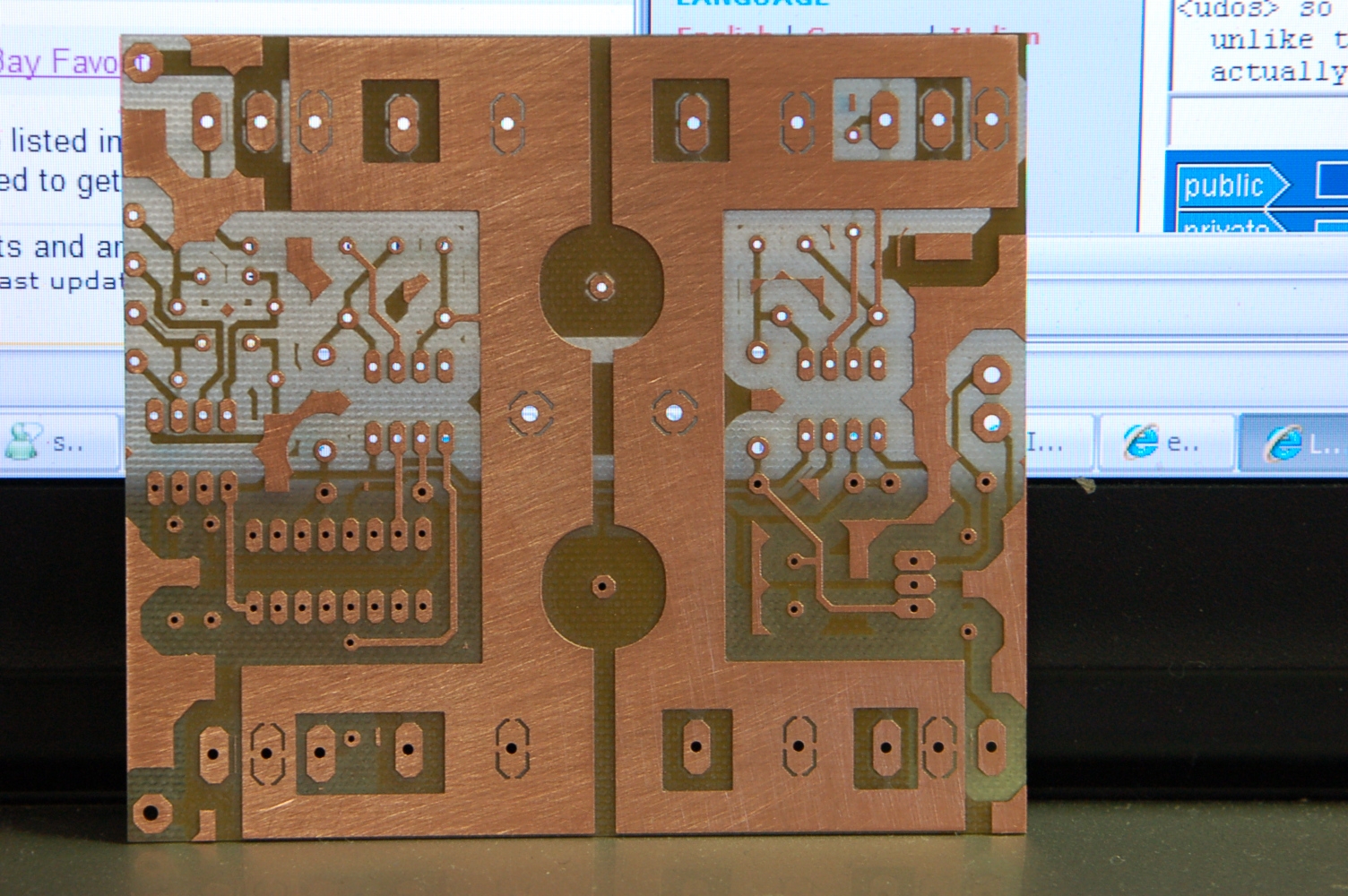

Here is a pic of my first milled PCB. It was done a while back and I never built the stepper driver it was milled for, but it came out pretty good.

Jason

Thread: First milled PCB

Results 1 to 20 of 37

-

03-03-2008, 01:59 AM #1

Member

Member

- Join Date

- Dec 2004

- Posts

- 1316

First milled PCB

-

03-03-2008, 03:36 AM #2

Member

Member

- Join Date

- Feb 2007

- Posts

- 966

What software did you use to make that ?

-

03-03-2008, 11:45 AM #3

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

-

03-03-2008, 12:36 PM #4

Member

Member

- Join Date

- Dec 2004

- Posts

- 1316

I set the grid pattern to 1.27mm in a CAD program as the perfboard that was to be used was 2.54mm spacing. I also created a set of points fro the drill holes

I then imported the dxf into Vcarve Pro and created the toolpath.

Jason

-

03-03-2008, 12:36 PM #5

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

Lots of good stuff here http://www.mr-bean.co.uk/pcb_stuff/pcb_stuff.html

John

-

03-03-2008, 12:41 PM #6

Member

Member

- Join Date

- Dec 2004

- Posts

- 1316

If you want PCB design software you could check out www.diptrace.com.

Jason

-

03-03-2008, 12:43 PM #7

Member

Member

- Join Date

- Dec 2004

- Posts

- 1316

-

03-03-2008, 02:10 PM #8

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

This thread has lots of useful information and might have the pictures you are thinking about http://www.cnczone.com/forums/showthread.php?t=23363

John

-

03-03-2008, 02:25 PM #9

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

http://www.cnczone.com/forums/showth...B+tool+milling

http://www.cnczone.com/forums/showth...B+tool+milling

http://www.cnczone.com/forums/showth...B+tool+milling

http://www.brusselsprout.org/PCB-Routing/

I have a little spare time so I’ve had a quick look for some more useful threads that may be of interest. I haven’t personally read through them so take them as they come.

Maybe it would be worth starting a new thread just for useful links to get the beginners started?

John

-

03-15-2008, 02:05 AM #10

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 26

Those links were very helpful. thanks dude. I am just starting to build my machine for mostly this purpose, however I will make it big enough to do larger project with wood or aluminum.

Thanks

Haku

-

03-15-2008, 02:18 AM #11Phil, Still too many interests, too many projects, and not enough time!!!!!!!!

Vist my websites - http://pminmo.com & http://millpcbs.com

-

03-15-2008, 04:51 PM #12

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 26

Does anyone know what bits etc that he used for those mills. They look really good, that is the kind of precision that I would like.

Thanks

Haku

-

03-15-2008, 05:27 PM #13

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

I really like thinktink cutters..

http://www.thinktink.com/stack/volum...e/mechmill.htm

This was done with 60deg mech etching bit and 1/16 cutter. I use eagle ( http://www.cadsoftusa.com/ ) and one of the various scripts that export g-code. Like http://groups.yahoo.com/group/pcb-gcode/

-

09-26-2008, 02:23 AM #14

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 84

the best

-

09-26-2008, 03:47 AM #15

Those are Drewtronics 45 degree bits. http://www.drewtronics.net/

The thinkntinker bits are good bits, but I think they are more fragile and don't last as long. Plus they are more expensive.Phil, Still too many interests, too many projects, and not enough time!!!!!!!!

Vist my websites - http://pminmo.com & http://millpcbs.com

-

10-09-2008, 05:36 AM #16

Gold Member

Gold Member

- Join Date

- Apr 2005

- Posts

- 1778

I made my first try at milling a PCB today. I cut it on my CNC Router with a PC690 router and a 1/32" carbide endmill. The drilling worked OK (not great) but the bit was really too large for the isolation milling. I have ordered a couple 0.010" x 1.8" - 50° carbide engraving bits from Bits & Bits. I'll try again when they arrive.

My guess is that the router is never going to produce beautiful boards but I hope that it will solve my immediate problem.

I used pcb-gcode 3.3.3 to produce the gcode and the gcode optimizer by Daniel P and Jay C.

I have my XY feed set at 10ipm and my Z feed set at 5ipm. Does that sound about right?

Alan

-

10-09-2008, 09:55 PM #17

You can get quite usable results with the PC router. 10ipm is in the range, probably low for that size cutter. When I am removing 4 mils then I get to 8 to 10ipm. 8 to 10 mils 14 to 18 ipm. Depends on trace width and how delicate you need to be for trace width. Finer traces can't handle rough cutting.

Phil, Still too many interests, too many projects, and not enough time!!!!!!!!

Vist my websites - http://pminmo.com & http://millpcbs.com

-

10-10-2008, 04:45 AM #18

Gold Member

Gold Member

- Join Date

- Apr 2005

- Posts

- 1778

Phil,

I got my new bits today and I cut another board. It came out worse than the first one. The 1/32" endmill cuts nicer but it is too big. So I adjusted the board and made the via pads larger and tried again. That worked out alright but my 0.030" traces are coming out only 0.020". I am working on rebuilding the router (along with a lot of other projects), so it will have to do for now.

Alan

-

10-12-2008, 01:39 AM #19

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

another board. You can see what happens when the vaccum pump shuts off during the final cut.

Oh well - still will work to proof the circuit.

Oh well - still will work to proof the circuit.

http://www.electronicsam.com/images/...t/DSC_5099.JPG

http://www.electronicsam.com/images/...t/DSC_5094.JPG

sam

-

10-24-2008, 06:49 PM #20

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 116

I used Eagle and the ulp file to generate the g-code as mentioned in this thread. I looked at it in CAMBAM and saw that each routed line has almost five passes. That is what was making the file so big. Over 11,000 lines. What settings in the ulp did I not set correctly?

I have set the etching tool size to 0.01 and then to 0.04. The file was smaller with the later but not by much. I want to use a 0.032 tool.

Yoram

Similar Threads

-

Turned/Milled Delrin.

By LateNight72 in forum Employment OpportunityReplies: 11Last Post: 01-22-2008, 12:33 AM -

I need some slots milled in some 14 ga SS.

By Jeff Wohlt in forum Employment OpportunityReplies: 2Last Post: 10-31-2007, 11:02 PM -

Anyone need something turned/milled (manual)

By skmetal7 in forum Employment OpportunityReplies: 2Last Post: 08-03-2007, 05:11 PM -

RFQ Al plate/milled

By roninB4 in forum Employment OpportunityReplies: 8Last Post: 09-07-2006, 07:23 PM -

Never milled but have a project

By mikesativa in forum MetalWork DiscussionReplies: 9Last Post: 03-22-2006, 08:24 PM

Reply With Quote

Reply With Quote