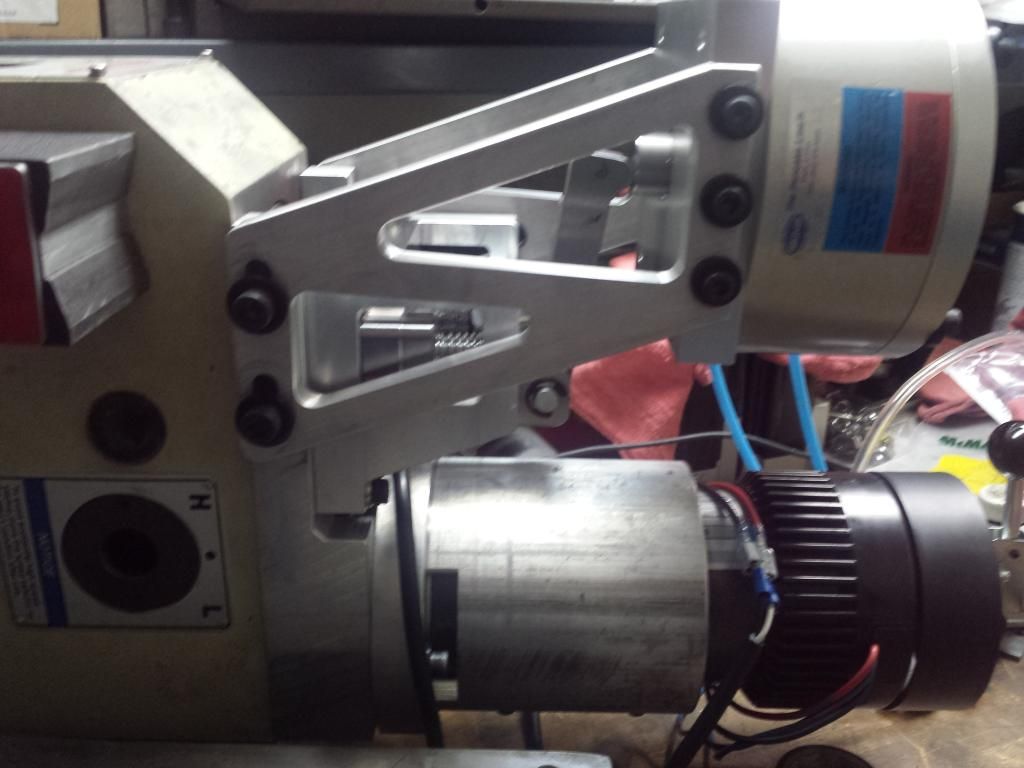

I finally finished my high tension power drawbar based on Hoss's design (Thanks Hoss!), but I changed his design so that it works using a single stage 3" air cylinder instead of a multistage type. I simply got tired of waiting for one to go on sale on ebay and didn't want to make my own since I had already sunk money on a 3" and 4" cylinder. I had hoped that the 4in cylinder could do the job using Hoss's LD drawbar but I kept getting pullout whenever I pushed the feed/speed too high so it was time to upgrade to the high tension version.

Attachment 236690Attachment 236692

I had some trouble with the Mark-I in a couple of areas. I had to reinforce the shoulder bolts to prevent them from bending and extended the shoulder bolt guide on the lift plate to keep it from tilting. I didn't have the right sized reamer for a sliding fit on the shoulder bolt so there was too much play in that area. The extended shaft around the shoulder bolt helped reduce the amount of tilt on the lift plate.

With the 3" cylinder I get ~2400 lbs force @ 120 PSI and that would go up to ~4300 lbs with the 4" cylinder! So far I've had no pullout using the 3" cylinder. It's soo great to be able to push my feeds/speeds now and not worry about pullout until I go too far and stall the motor...and we all know how that story goes, upgrade stock motor, add belt drive, etc. endless upgrades!

Here it is in action. Sorry, I don't have a video camera.

Attachment 236694Attachment 236696

I hope this gives you guys some ideas for making your own high tension drawbar, but if I had to do it all again, I would machine the lift plate out of a single piece of metal, use a proper sized reamer for the shoulder bolt and make the air cylinder side brackets part of the base legs that hold the shoulder bolts.

Results 1 to 20 of 37

-

05-17-2014, 03:28 AM #1

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

High Tension Power Drawbar Using 3in Cylinder

-Leo

High Tension Power Drawbar Using 3in Cylinder

-Leo

-

05-17-2014, 06:58 AM #2

Member

Member

- Join Date

- May 2008

- Posts

- 1185

Re: High Tension Power Drawbar Using 3in Cylinder

That looks rather nice.

Did you make the nut that looks to be holding the air cylinder in place?youtube videos of the G0704 under the name arizonavideo99

-

05-17-2014, 05:17 PM #3

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

That huge nut came with the Bimba cylinder.

-Leo

-

05-18-2014, 02:12 PM #4

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

Do you have plans that you are willing share? I have a 4" fabco pancake cylinder that I bought and tried to make a side mounted setup. It didn't really work out :tired:.

What kind of mechanical advantage are you getting on the lever?

Thanks

Andrew

-

05-19-2014, 12:11 AM #5

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

I don't mind releasing the plans. Give me a couple of weeks and I'll put together a set of drawings and BOM.

The lever ratio is set to 2.85:1 which gives you about 2400 lbs force using a 3" cylinder @120 PSI. With a 4" you'll get upwards of 4300 lbs which may be more than you need for these belleville washers (can't recall the rating) so you may be able to use larger ones if you need more holding force. If using a 4" cylinder, I would probably use larger screws on the base legs that hold the shoulder bolt since there's allot of force on the rear screws as the whole thing wants to tilt forward.-Leo

-

05-19-2014, 12:55 AM #6

Registered

Registered

- Join Date

- Nov 2003

- Posts

- 287

Re: High Tension Power Drawbar Using 3in Cylinder

Which belleville washers are you using?

-

05-19-2014, 09:11 AM #7

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

So I'm trying to figure out how to calculate the pressures on this setup. Not because I don't trust you, but I just like to know how things work!

So using this calculator Simple Force Level Calculator Case #3 - Engineers Edge Engineering Calculators

W = 4300

L = 2.85

X = 1

It gives me 1508 for F, which is the PSI I get using this pressure calculator for cylinders @ 120 PSI, 4"bore (your specs form above)

Am I on the right track?

thanks,

Andrew

-

05-19-2014, 09:19 AM #8

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

Also, would this setup put pressure on the spindle bearings? Given it has the lift plate, I would think not. But the cylinder is mounted to the head.

It seems to be a hybrid between the two different ones that Hoss has plans for.

Andrew

-

05-19-2014, 01:32 PM #9

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: High Tension Power Drawbar Using 3in Cylinder

This design is lifting the top hat or the part right below the bellevilles. Just like Hoss' design.

A lazy man does it twice.

-

05-19-2014, 05:01 PM #10

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

McMastercarr #9712K436, they flatten out at 2,698 lbsWhich belleville washers are you using?

Yes that's correct, but 2.85 is the lever ratio, not the actual length. Using that equation, it still works out to the same value.W = 4300

L = 2.85

X = 1

It gives me 1508 for F, which is the PSI I get using this pressure calculator for cylinders @ 120 PSI, 4"bore (your specs form above)

Am I on the right track?

It doesn't put any pressure on the bearings. Like Fastest1 described, the lift plate moves up and squeezes the washers with the top hat. The cylinder is mounted on the head in similar fashion to Hoss's LD drawbar, but instead of directly acting on the drawbar, it now applies the force on the lever. As you guessed, this design is a hybrid of several of Hoss's plans.Also, would this setup put pressure on the spindle bearings? Given it has the lift plate, I would think not. But the cylinder is mounted to the head.

It seems to be a hybrid between the two different ones that Hoss has plans for.-Leo

-

05-21-2014, 06:49 PM #11

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 291

Re: High Tension Power Drawbar Using 3in Cylinder

Very nice. I am interested to build one for my Tormach before the year is out.

-

05-28-2014, 05:14 PM #12

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

BOM and drawings attached in zip file.

-Leo

-

05-29-2014, 09:06 AM #13

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

First, thank you for the files!

Second, do you think there is enough weight to push out the collet if the top hat is not threaded?

The only other thing I need to do is figure out if I am going to cut down my belt drive motor risers or mod your design? May have to move the motor back as well and get a longer belt.

Thanks again,

Andrew

-

05-30-2014, 01:52 AM #14

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

To be honest I don't know. Hoss mentions in his plans that there might be issues with the top hat so I decided to make one with the internal threads and avoid any problems. I'm no machinist by any measure and I managed to do the internal threads on my mini lathe on my first try.

Once you have it worked it out, please post pics of your mod. I have no doubt I'll be going to a belt drive sooner or later no matter how much I try to convince myself I don't need it. -Leo

-Leo

-

05-30-2014, 02:15 AM #15

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

I missed something on one of the drawings, so here's the updated version.

Anyone know if there's any way I can edit the first post in order to maintain the files with the latest versions?-Leo

-

05-30-2014, 09:17 AM #16

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

I don't have a lathe of my own yet. and the manual at work is set for inch threads. the ez path can do it, as well as the new HAAS TL-15 but I'm one of the "cool kids" that get to play on the new machines. I was just trying to skip a step.

I'm going to have to pull my mount risers to mill the sides down so I'm just going to mill the front end down to the height of the stock plate that comes on the mill.

Andrew

-

06-01-2014, 06:09 AM #17

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

By the looks of things your motor will definitely be in the way. You could try rotating my design sideways but it may be easier to just move the motor back like you mentioned.

-Leo

-

08-06-2014, 05:33 AM #18

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: High Tension Power Drawbar Using 3in Cylinder

Finely got my version of your power drawbar to the point of working.

There are a few things that worry me though......

1. in order for it to release the tool I have to turn the draw bar about 1/4 turn from the collet. I am using the same springs in the BOM. As I under stand there call out, you have to compress each spring .025" to get to the load pressure.

So .025" X 6 = .150" (depth needed to preload the springs)

Drawbar is a 7/16 x 20.... 1" / 20 = .050" per turn (thread)...... So 3 turns in will get me the preload needed. But at 3 turns it will not release the tool?

2. When the drawbar is activated, it pushes the spindle out .005". So me thinks this design still puts pressure on the spindle bearings

Any thoughts?

Andrew

-

08-06-2014, 03:47 PM #19

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 101

Re: High Tension Power Drawbar Using 3in Cylinder

It could be the lift plate is binding on the shoulder bolts since the lift plate wants to tilt when activated. You should be able to lift it up using your fingers, if not, then it may be slightly out of alignment. I had to enlarge the guide holes slightly due to alignment issues on my machine.

Ideally a linear bearing should be used to eliminate any binding issues but I wanted to keep it as simple as possible. A simpler solution might be to use a lubricated bronze sleeve bearing.

I also had to loosen the lug nut until it just releases the tool. I have TTS holders from different suppliers and not all of them released due to small differences in dia on the shaft. I've had several crashes and no pullout with the 3" cylinder so the pre-load is fine for me. With your 4" cyl you should be able to max out the pre-load so I suspect it's a binding issue.-Leo

-

08-06-2014, 05:24 PM #20

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: High Tension Power Drawbar Using 3in Cylinder

The potential side loading in that design always made me wonder. I wanted to use a much smaller cylinder since there was a leverage advantage.

A lazy man does it twice.

Similar Threads

-

CNC Lathe recomm. for high vol. cast iron cylinder liners

By timo2le in forum Want To Buy...Need help!Replies: 2Last Post: 03-07-2011, 03:56 PM -

Milacron 15VC machining ctr drawbar cylinder

By ganzelc in forum Cincinnati CNCReplies: 0Last Post: 01-01-2011, 05:46 PM -

Fluid for 96 4020HT drawbar/high/low?

By ThatguyDave in forum FadalReplies: 4Last Post: 07-14-2009, 07:56 PM -

Drawbar Tension....

By SCzEngrgGroup in forum Bridgeport / Hardinge MillsReplies: 23Last Post: 06-17-2009, 05:01 AM -

Hitachi Seiki MH 400 drawbar tension

By kmuller in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 11-07-2003, 08:10 PM

Reply With Quote

Reply With Quote