Hello,

I am considering a 2010 ShopMaster Patriot and wanted to solicit some feedback

on this, because I am wavering a bit. I am primarily interested in from a hobby

perspective - have some limited experience on knee mills and lathes (Jet). What

I find interesting in the Patriot is the potential for space savings and the cnc option

(I have no experience with this, but am a software developer by trade and have

been itching to dink around).

So some general questions about the ShopMaster (and combo machines in general)

is the ability to get accuracy out of them. It seems they lack the ability to tram

the mill head. The fact that the ways are used for both the mill and the lathe would

seem to conflict how to adjust both the mill and the lathe as well. Can someone

enlighten me a bit here? I have searched around to no avail.

WRT the CNC capabilities of the Shopmaster, any comments here? Can it be used

in the manual mode as well with this option?

Any general comments regarding the quality of the machines now that they are being

manufactured in ISO-certified plants? Anybody check the tolerances as published?

Maybe ShopMaster does before sending out?

If anyone is in the SF bay area (or thereabouts) willing to share a peek and experiences,

it would be much appreciated.

Regards,

--Dan

Results 1 to 11 of 11

-

12-08-2010, 07:07 PM #1

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 4

Potential Shopmaster Patriot Customer on the Fence

-

12-12-2010, 01:16 AM #2

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 38

I haven't had mine for very long, but when I first got it I couldn't machine anything without horrible vibrations. Luckily, all it turned out to be was the gib strip on the x axis had a real low spot. Once I sanded it down flat, vibrations went away, so everything is good now. As far as the accuracy, I'm still lacking a few essential measuring tools, so I won't be able to check for a while. I'm also researching some of the different cad cam programs, so I won't be cutting parts by way of cnc for a few more weeks. It may be a while, but I'll post back as soon as I do.

-

12-12-2010, 03:12 PM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

Overall, I think they are a good value for the dollar, especially for entry level work- to get higher precision, you will most likely have to invest in a seperate CNC mill such as a Tormach and maybe one of the other Chinese CNC lathes- but your costs will go up by a factor of 4 or 5 and your space reuirements will be at least triple.

-

12-20-2010, 09:06 PM #4

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

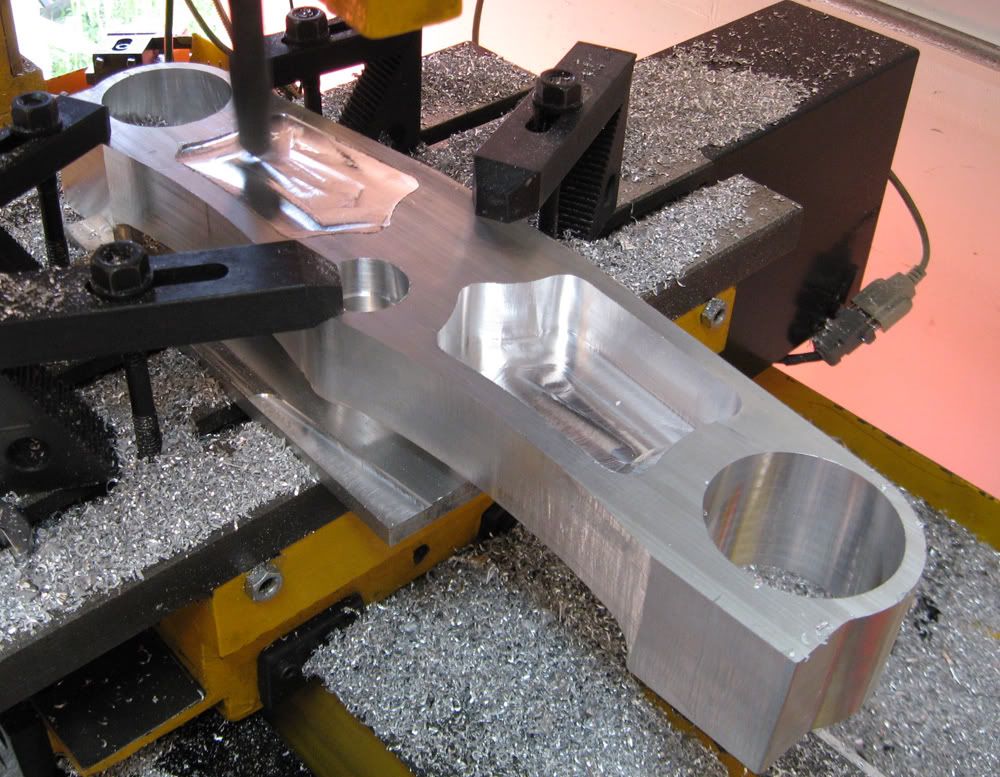

For the money, they are hard to beat. You can machine just about anything, so long as it fits in the machine. The biggest thing to remember is that they don't have much mass to them.. Therefore, you can't take very big cuts. You say you need something from a hobby perspective, they are great for that. I have the Tri-Power machine, but it is set up like the newer Patriot. In fact, I'm gonna upgrade to the newer drive motors next. I have the CNC and DRO on mine and use them both.

Here are some pics to the most involved project I've done on mine: Tripple Clamps for a custom motorcycle I built.

-

12-30-2010, 04:00 PM #5

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 3

Hi everyone,

Please forgive the anger, but I have a great deal of experience with Shoptask, both the machines and the company. They are garbage, the owner is trying to sell the company (he solicited me, among others) and they require a great deal of work right out of the box. They will hold nowhere near the .001 tolerance they claim. If you really want one and are willing to take the time to message it (extensively!) buy one used!!! Just a friendly warning!

-

12-31-2010, 01:05 AM #6

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 180

-

01-02-2011, 05:51 AM #7

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 14

I would never buy one again. I have had mine for two years. I had to pull every gear case apart and clean out a bunch of sand and metal cuttings. I did turn it in to CNC. I have adjusted and adjusted. I would buy two machines. A CNC Mill and a Lathe. Save the aggregation.

-

01-02-2011, 03:21 PM #8

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 180

Dan,

I think the biggest error people make is in their expectations. If you are realistic about buying a machine tool in this price range, then you will be satisfied with the product. Those people who are trying to get by with a Chinese combo machine when they need a Haas are going to be very unhappy.

Shopmaster had a close-out sale in '09 when one of their old factories closed and they were selling the machines for around 1800.00. I bought one of these and found some QC issues, but I figured that when a factory is closing, the QC is going to suffer. Since I was prepared for it, it was not a surprise. As part of my overall plan, I simply planned to disassemble the machine completely upon arrival and do my own QC. That worked out great for me, as the machine is really not very complicated, and it only took me about a week total to tear it down, clean everything and re-assemble to my own liking. After that, it worked fine and I have been very happy with the results. The new machines are coming from a newer factory with better equipment and better QC, so that may no longer be necessary.

-

01-02-2011, 08:52 PM #9

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 77

jdclark and Mrbracket, I PM'd you. I don't want to hijack the thread. Get back to me if you can.

-

01-04-2011, 09:47 PM #10

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 4

I appreciate everyone's input. I did actually go with a Shopmaster - prior to more of the

negative comments, but I had seen similar so wasn't caught off-gaurd by these (they

were appreciated though).

Factors for the purchase were primarily because of the space limitations. I had

tempered my expectations wrt accuracy and capacity. I was looking for something

that was capable of manual and CNC operations and that pretty much limited the

universe of possible solutions.

For the record, I did look at a lot of used machines of various types, including older

shopmasters and smittys as well as used standalone equipment. I have a good

handle on what the combos command in the aftermarket (at least in this area),

so have a good idea of what I have on the line.

I will feedback general comments and experiences as I spend a bit more time with the

machine.

Regards,

--Dan

-

01-04-2011, 11:29 PM #11

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 77

Good luck with your purchase! I bought one of the close-out machines they offered a couple of years ago. I went into it knowing and expecting there would be issues and I'm actually having fun working on it and being a total newbie, it's helping me to understand how all this stuff works. Keep us updated as to how your machine's working out. I'm curious to see how much, if any better the new machines are from the new factory. I'd also like to see if they have the infamous "table rock" issue.

Similar Threads

-

Buying a Shopmaster Patriot

By Ira in forum Shopmaster/ShoptaskReplies: 84Last Post: 10-24-2011, 01:49 AM -

Tramming a Patriot Shopmaster

By gearhead dan in forum Shopmaster/ShoptaskReplies: 0Last Post: 08-12-2010, 07:06 AM -

GOT MY NEW SHOPMASTER PATRIOT

By smallblock in forum Shopmaster/ShoptaskReplies: 22Last Post: 02-24-2009, 12:23 PM -

Sittin' on the fence

By stoneyreef in forum Joes CNC Model 2006Replies: 10Last Post: 01-12-2009, 06:25 PM -

My DIY Shaper Fence

By golash in forum WoodWorking TopicsReplies: 1Last Post: 08-17-2007, 04:12 AM

Reply With Quote

Reply With Quote