Always been wanting to learn cnc so since it is my B-day thought i would order the mill and components to build one.

I order the mini mill from

HiTorque Mini Mill, Solid Column with Precision Tooling Package - LittleMachineShop.com

Motors and drive from

G540 3-Axis NEMA23 381oz in PSU48V/7.3A | Automation Technology Inc

I also order some other odd and ends from other places mainly consumables.

initial motor run

Results 1 to 11 of 11

-

11-24-2013, 02:14 AM #1

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

My little machine shop mini mill build.

-

11-24-2013, 05:02 AM #2

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

on the E-stop circuit, is it better to put it on the ac side of the power supply or on the dc side?

-

11-24-2013, 05:43 AM #3

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 20

You want the E-Stop action to cut power to the drivers, and spindle. Most boards and/or drivers have an enable pin, which must be on for the amp to turn on. Also, most boards have a connection for the E-Stop signal. Breaking this enable signal will stop motion. In the case of the Mach3 control signal, if the computer program is not on, and in control of the system, the enable signal will be disconnected through the charge pump relay. This is a safety feature, to prevent motors and spindle from starting up before the program is on, and in control of the outputs.

John

-

11-24-2013, 05:26 PM #4

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

I have it to kill all power going to the power supply.

I figure it will stop everything if there is a problem.

-

11-25-2013, 05:03 AM #5

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 73

Love that little mill. Might be one in my future someday. Are you going to post a build thread here so we can follow your progress?

Chuck

-

11-25-2013, 05:08 AM #6

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

Yes I plan to post pictures and some videos while I am building it.

And most likely will have question when doing it.

Waiting on the screws to arrive from cncfusion.

The look like they will be at my local UPS center tonight but not scheduled to be delivered till Tuesday. I am going to check in the moring if they are not going to be delivered till tuesday I am going to call and see if i can pick them up.

-

11-26-2013, 06:58 PM #7

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

Still waiting for the screws to show up.

Forgot I had a Tachometer to install so i added it today.

Got it from

Macpod Software: Hacking the SX2 Mini Mill - (Adding a reverse switch and reverse engineering the tachometer port protocol)

Now if the ups guy would get here with the screws and I will be happy.

-

11-27-2013, 06:23 AM #8

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

Got it together, had some issues with the mounts but have a couple temporary fixes. waiting for a reply from cncfusion on them.

I'll take a video tomorrow, think i got a little confused on the + and - direction of the x and y axis.

Then my keyboard keeps disconnecting and was being a pain in the ass. It went flying across the shop into the trash can.

-

11-28-2013, 03:37 AM #9

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

Got the first cnc run by the computer.it is just a air cut to see if I am close with the settings.

-

12-29-2013, 06:16 PM #10

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

had some issues ended up messing the drive up had to send it back for repair.

Also order a second drive incase i mess it up again.

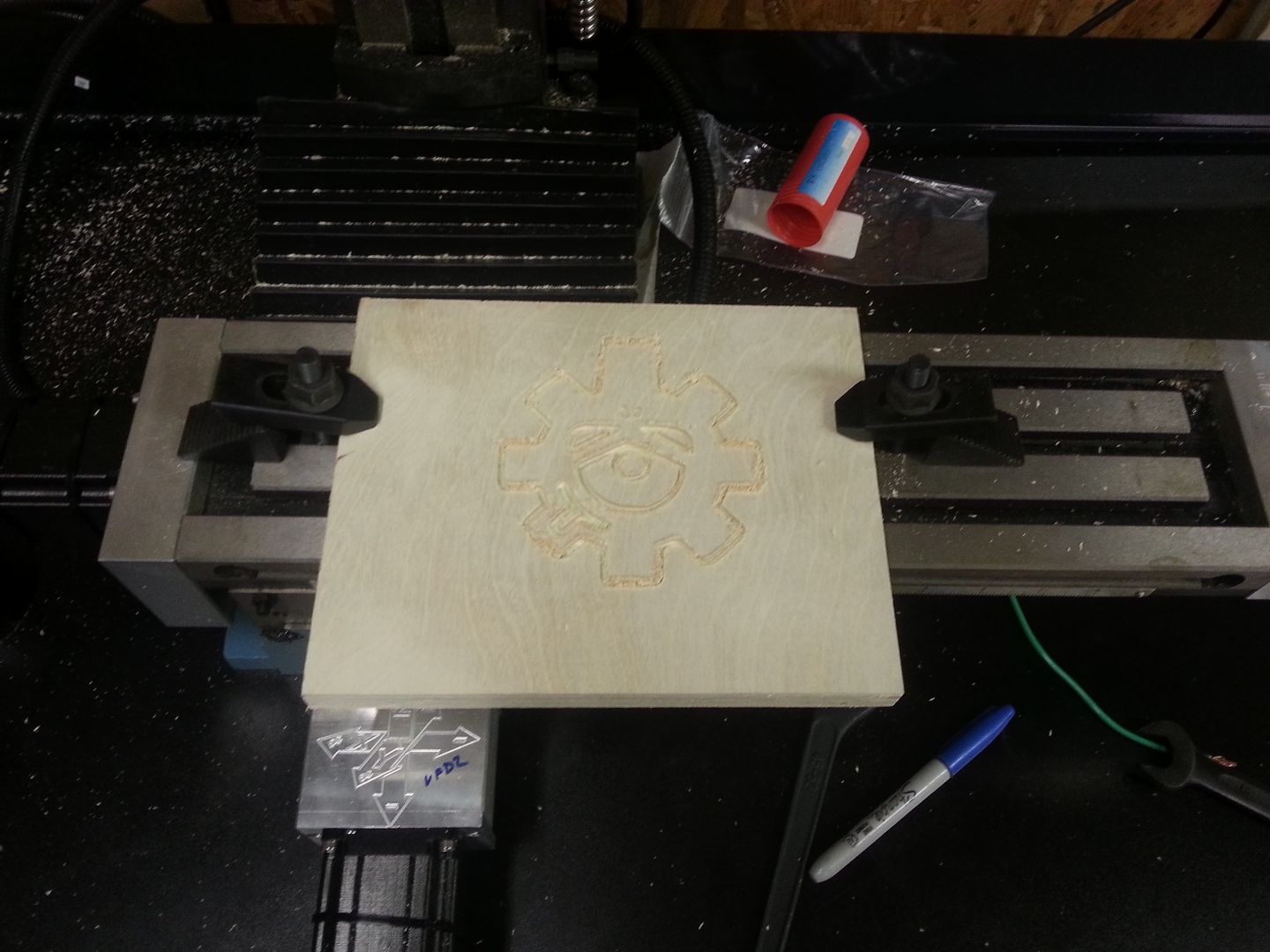

Well my finished first cnc carve on my mini mill.

Took the image from Google.

Used Inkscape to create a .dxf file

loaded it in CamBam to generate the g code.

Open gcode in Mach 3 to create the carve.

Only 2 days to figure out how to do a simple 4x4, 2 min carve.

But learned lot doing it.

-

12-29-2013, 06:20 PM #11

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 31

my next attempt

short video of it running,

took image from google

converted into .dxf file,

used Cambam to produce gcode

mach 3 to run.

This time about 30 mins from finding image converting it to finished cut.

I did get a lot of help from the members of CamBam and mach 3 forums to get my mill running.

I do have a ton to learn and i don't think everything is set up correctly.

It works and the issues probably will be figured out as i go along.

Reason i am staying with wood for now.

Similar Threads

-

Need some direction to build a small machine to allow me to build a larger one

By Dman65 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 01-05-2013, 05:24 AM -

CNC diemaking shop needed to build tooling from my SolidWorks models

By PhoenixMetal in forum Diemaking / DiecuttingReplies: 18Last Post: 01-19-2011, 04:15 PM -

Use Machine Shop vs. Buying Machine

By imp22b in forum MetalWork DiscussionReplies: 15Last Post: 06-06-2007, 12:33 PM -

Home Build CNC for School shop.

By mwalach in forum Community Club HouseReplies: 39Last Post: 06-06-2007, 01:49 AM

Reply With Quote

Reply With Quote