Anybody have good or bad experiences working with this company?

UGRAcnc

Thanks,

GG67

Results 1 to 15 of 15

-

02-02-2012, 11:03 PM #1

- Join Date

- Nov 2011

- Posts

- 33

Any Experience With This Company?

-

02-06-2012, 01:36 AM #2

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Andy at ugracnc is awesome. I ordered a 2.2kw watercooled spindle, a momentary on/off power button, estop, and some 18power wire from him.

Obviously the spindle was more than the china sellers on ebay. Andy personally powered up my spindle and checked its runout before sending it to me. Then he did the ultimate thing - he made a video of MY SPINDLE and put it on youtube and sent that to me before shipping it out. How awesome was that??!! That is the biggest RISK I have read about on the spindles is what if it does not work or has issues when it arrives.

Andy gives a warranty on his spindle if they are bought direct from his site. Thats what I did. He is also in Pensylvania and you can call and talk to him if you have questions. That was my second issue with buying a spindle from China.

His 2.2kw spindle came with a larger connector on it than most but I still changed it out to a amphenol ecogate connector from digikey - thanks to GaryD for that recomendation. I do not like soldering those little cups on teh chinese connectors. His does have four pins on it - only the three motor ones are used so you can add a ground to the 4th.

His power buttons and estops might be the best deal I have found for an E stop. I have been using them on my friends controller builds I do for them since I have found them. I also like his limit mechanical switches and all I have tried have been the cheaper red one. He sells what look like much nicer ones than those.

His 18ga power wire is shielded and I use it for the home/limit switches. I bet you could use it for power wire on teh spindles. I choose to go with Igus CF31 16ga 4 conductor powere wire - that is the best power wire for a spindle on a cnc machine I have found. Thanks to diyengineer I think that gave me that power wire recomendation.

Andy and I have become online friends and talk every couple weeks. He is a cool CNC seller and I keep on him to keep this niche of providing spindle checkout pre sale support. I think that is SOO worth what little extra he is charging for a spindle. By the time I was into buying the 2.2kw for my machine the extra coin was not an issue.

Also, I have been on him to sell Hitachi VFDs I am a fan of the Hitachi x200 022nfu2 VFD I bought for his spindle. Diyengineer also sent me to that VFD. Thank you DIYEngineer!

I am a fan of the Hitachi x200 022nfu2 VFD I bought for his spindle. Diyengineer also sent me to that VFD. Thank you DIYEngineer!

Andy rocks and I hope he continues to sell parts and expands his line up.

He also has a machine for sale on ebay that looks very very heavy duty for a smaller ball screw machine!

Here is the spindle I bought from him cutting a paradise box top - a free vectric vcarve pro file that Mike gave the community - Thanks Mike!!

[ame=http://www.youtube.com/watch?v=Gs2l51y3o2w]Spindle cutting Megans Jewelry box from some free Vectric Files - Thanks Michael for making those! - YouTube[/ame]

Here is the walk around of my spindle setup. I added the spindle to my castcnc setup so thats why I added a nema box.

[ame=http://www.youtube.com/watch?v=x24rP5n0RNw]Modbus controlled Hitachi X200 VFD, 2.2kw 3Hp Chinese Spindle, Spindle Water Cooling all installed! - YouTube[/ame]Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

02-07-2012, 09:34 PM #3

- Join Date

- Nov 2011

- Posts

- 33

Thanks

Thanks for the thorough reply. I will definitely be considering UGRAcnc for my project.

GG67

-

05-13-2012, 04:18 PM #4

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

I have been trying to find this ecogate connector and am not having much luck. This is the only post on cnczone that mentions ecogate, and a search of digikey for ecogate returns nothing. If anyone has more information on these connectors like part numbers or a specific ordering link it would be enormously appreciated.

Thanks

BobC

-

05-13-2012, 04:28 PM #5

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 664

-

05-13-2012, 05:23 PM #6

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

Yes thanks, that helps a ton. It is ecoMATE not ecogate...

I had been on the first link....but they were all male connectors and none were blue, that's all a search for ecomate returns on the Digikey site for some reason.

The PDF was the eye opener.... Saw the Female connectors Blue and Black and then searched by part number and BINGO!!

Saw the Female connectors Blue and Black and then searched by part number and BINGO!!

Not sure why they didn't get listed with a search for ecomate....

Anyway thanks again!!

BobC

-

05-16-2012, 11:12 PM #7

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

Ok, now I'm confused again...

I ordered the part from DigiKey 361-1362-ND CONN FEMALE PLUG 3+PE GOLD BLUE.

It looks right, but the 4 female plug holes are 1/4" apart. The pins on the 2.2kw spindle I got from Ugracnc are about 3/16" apart....the plug won't fit. I don't see anything on the datasheet specifying that dimension.

Anyone have any ideas?

Thanks!!

BobC

-

05-17-2012, 02:21 AM #8

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

I looked at th elistings and if you click on the PDF at the bottom of the listing there is a little info. The only two things I seen that might help with size was by measuring the diameter of the connector itself, and possibly wire size also may determean the over all size. Really it looks like if the outside siameter was right then it would be right but IDK.

Also one other thing was they are either soldier connectors, crimp, or screw connectors. This would be something to help go by also.

JessGOD Bless, and prayers for all.

-

05-17-2012, 03:09 AM #9

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

Thanks for the reply Jess.

Yea, it's definately strange...the diameter of the connector is actually correct, just the hole/pin spacing is wrong. And I also thought maybe the different connection types would make a difference but couldn't find any indication that screw connected pins would be spaced any different than crimped....for now it is a mystery...

Worst case I'll bite the bullet and solder on the connector that came with the spindle...not exactly my fortay... :drowning:

-

11-12-2012, 09:04 PM #10

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

I just now read this sorry.

Here is a male part - you order male and femal plugs seperately. click their catalog to see the other parts.

Digi-Key Part Number361-1345-ND

Digi-Key Part SearchJoes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-12-2012, 09:58 PM #11

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

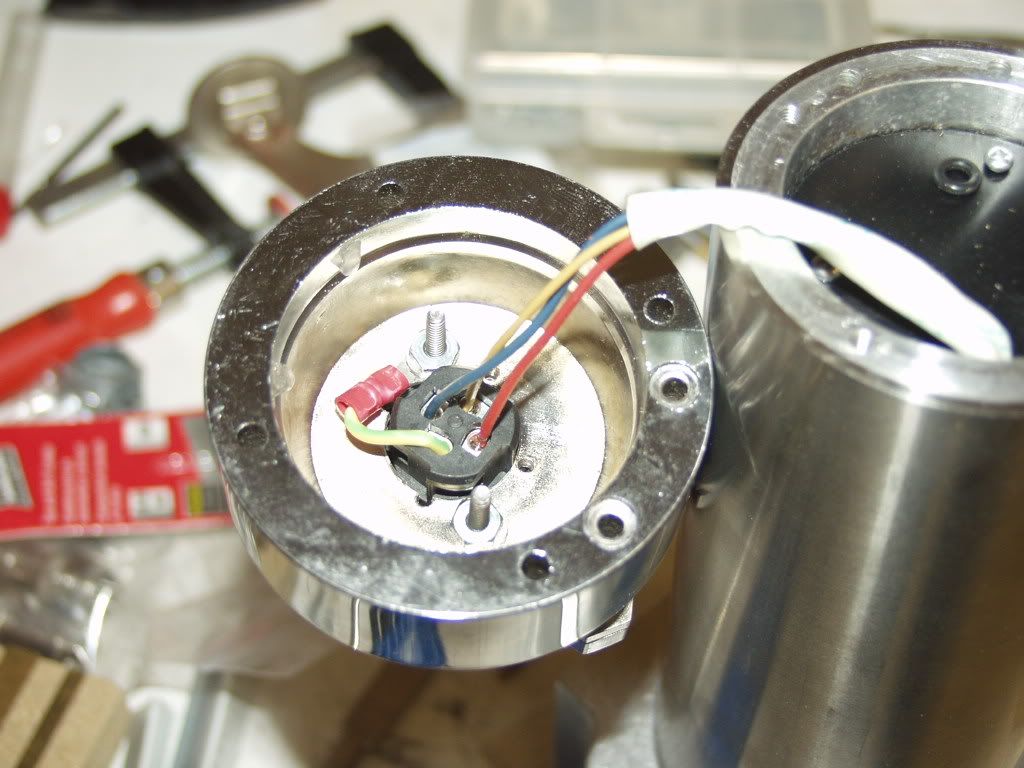

Also just so everyone knows, I changed out my receptical in my spindle too. I drilled out the spindle cap and installed the amphenol ecomate receptical in the spindle and attached a ground wire inside as well.

Here are more part numbers as of 11/12/2012.

361-1345-NDCONN MALE PLUG 3+PE SILVER BLACK3 (black plug)

361-1344-NDCONN MALE PLUG 3+PE SILVER BLUE3 (blue plug)

361-1081-NDCONN FMLE RCPT 3+PE SCREW SILVR6 (black receptical)

Here is change over of receptical.

Take off cap and remove old receptical.

Drill out cap for receptical and mount holes.

Put wires through cap and install receptical

Connect new ground to mounting screws - I provided my own screws.

Pic of installed receptical and plug attached.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-12-2012, 10:18 PM #12

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

i purchased nothing from them yet..

however i got help..

i had a single phase220 input inverter with a 1.5 kw spindle..

their pdf helped me figure i can wire the 2x110 properly, because inverter recognize automatically the input voltage..

thank you..

sure these products need some domestic distributor and its help..

spindles itself working very well..

-

11-23-2012, 12:27 AM #13

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

For others who want a USA sold Chinese made spindle, Andy at Ugracnc.com is the man. He tests the spindles before he ships them. He is an awesome spindle guy. He also sells the Hitachi VFD as well.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

02-07-2014, 10:58 PM #14

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 25

I'm reviving this dead and old thread to give a 2014 update on UgraCNC. I ordered a 0.8KW square style air cooled spindle about a week ago. It had been out of stock and I had to wait a couple weeks, but Andy was very good about answering my questions pre-sale.

I had some very specific technical questions regarding bearings and cooling. He was able to answer my questions and help me choose the spindle that would work for my application. I was initially concerned with the runout specification, since it is higher than the other Chinese spindles advertise. In my application it was extremely critical to have as little runout as possible. I will be cutting with 0.005" end mills, and any runout would cause tool breakage. I was pleasantly surprised when I checked the spindle I received and it has an unmeasurable amount of runout. I checked with a 0.00005" test indicator and the needle didn't even wiggle when checking the ER16 taper.

I am very happy with the build quality and it far surpassed my expectations for a Chinese spindle. It is obvious much thought went into the design, and that they took care to balance the assemblies at different stages. (there are drill marks from balancing on many parts) It was 2.5x the price of the Ebay spindles, but I believe the quality is better and the value is excellent.

Shipping was fast and with a tracking number. If you want a good spindle, I highly recommend one of the UgraCNC spindles.

-

05-19-2014, 08:19 PM #15

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 567

Re: Any Experience With This Company?

I have had a great experience with Andy from Ugra CNC.

He is knowledgeable about the products he sells, he is blunt in a rather good way, and overall the actual product is superb.

My 0.8KW spindle and .75 KW Delta M VFD was very easy to setup.

I have yet to even ground the shielding on my VFD cable, and so far I've had no electrical noise issues.

I've killed 2 Bosch Colts and 2 Dewalt 611s from routing wood, the spindle I have now makes them look like toys.

RPMs are nearly constant, the unit never chokes up, and overall it's a rather silent operation for being aircooled.

My cuts are cleaner, I can run lower RPMs, run my bits duller since routers are gutless wonders, and overall it was well worth the money.

The spindle is only taking 1 amp at 230 volts (I think) so I'm thinking the next spindle I'll buy will be .4KW, I've got to ask Andy on that one :-)

Overall if you have killed a router or three just buy a spindle from Ugra CNC.

Similar Threads

-

Anyone have experience with the company Industrial CNC?

By Dbl_Tap in forum Chinese MachinesReplies: 18Last Post: 02-16-2013, 10:04 PM -

Company wants to buy first cnc

By DWAS in forum Want To Buy...Need help!Replies: 6Last Post: 10-06-2010, 03:07 PM -

UK COMPANY/CNC

By haasmanuk in forum News AnnouncementsReplies: 0Last Post: 02-23-2010, 02:47 PM -

New Company in NZ

By nztomcat in forum Australia, New Zealand Club HouseReplies: 0Last Post: 10-20-2009, 01:22 AM -

Old Company name on pendant

By Conquest1224 in forum DNC Problems and SolutionsReplies: 1Last Post: 06-02-2007, 01:31 AM

Reply With Quote

Reply With Quote