Hello

I am hoping to get VERY VERY specific instruction on how to hook up my CandCnc DTHC into my PowerMax 45 that is using a Machine torch. Attached is a pic of a DTHC, numbered indicating connections. I can't get this to attach the pic, here is the link http://i820.photobucket.com/albums/z...THCdiagram.jpg

On the DTHC I need to hook up:

(1)TIP VOLTS POS goes to ________

(2)TIP VOLTS NEG goes to _________

(3)Arc goes to_______

(4)OK Switch goes to__________

(5)Torch Switch goes to _______

(6)Torch Switch goes to________

I have read many threads hooking the DTHC up to the PM45, but I haven't seen the install instructions precisely step by step written. Also, is there going to be any conflict using a Machine Torch with the DTHC? I ask because I think I have primarily read threads with modified Hand Torches being used.

Thanks,

Eric

Results 1 to 20 of 20

-

03-06-2010, 03:37 AM #1

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 55

CandCnc + Powermax 45 + Machine Torch =

-

03-06-2010, 02:01 PM #2

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

There will be no conflict using a machine torch.

I have at some point read CandCNC's instructions on the hook up but can't tell you what you need to know from memory.

If you didn't get a hard copy of instructions in the box with your product from CandCNC, If you will go to their Yahoo groups help site & look under the "files" section you should be able to find them, download & print the instructions.If it works.....Don't fix it!

-

03-06-2010, 04:18 PM #3

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 55

Thanks for the reply, but CandCnc does not have specific instructions for the PowerMax 45.

-

03-06-2010, 04:52 PM #4

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

Tom will most likely be on the board sometime over the weekend. I'd say he'll answer your questions when he sees the post.

Jim Colt can probably also help you. He also will most likely be on sometime.

If the HT45 hooks the same as HT 1000, HT 1250 etc. there should be several others that can help you through the hook up.

I'll be watching I am going to have to do the same thing with a HT 1250 G3.

Sorry I couldn't be more help at this time.If it works.....Don't fix it!

-

03-06-2010, 04:59 PM #5

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 55

Yeah, Jim is great. He has helped me with a lot of questions already.

-

03-07-2010, 06:25 AM #6

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

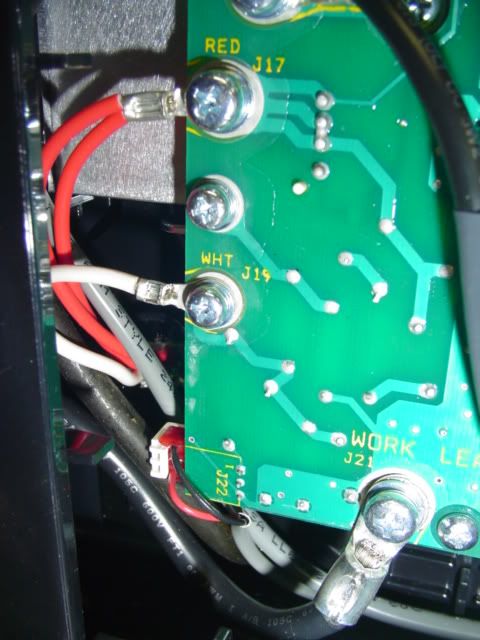

1- goes to j21 on the main board inside the unit.

2- goes to j17 on the main board inside the unit.

3- goes to pin 12 or 13 on the rear connector on the machine.

4- goes to pin 12 or 13 on the rear connector on the machine.

Connect one to 12 and the other to 13

5- goes to 3 or 4 on the rear connector on the machine.

6- goes to 3 or 4 on the rear connector on the machine.

Connect one 3 and the other to 4.

You have to buy a special cord from hypertherm to use the connector for the back or you can buy a 796271-1 amp connector and some pins form Newark for about $30 and make your one if you have terminal crimps. Thats what I did.

-

03-07-2010, 07:20 PM #7

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

Bigtoy302. Thanks for the response. I could not go past generic hookups for the 45. I have a 1000 G3 and our DTHC manual has the actual connection points and numbers for that specifc model. The names are the same but the connection points are different. There are hundreds of plasma brands and models our DTHC will work with and having specific step by step for each one is impossible.

If you can contact me direct I have a proposal for some trading for you if you are interested (I need a light duty press brake). I would also like to post your photos and response on the CandCNCSupport Yahoo Forum for future reference.

One side note: The START line inputs at the rear connector don't work to fire the torch with a hand torch because of the safety lockout.

I tried to download the 45 service manual from the Hypertherm website so I could at least give wire colors for the hand torch switch BUT I could not get the PDF to download (at least using Firefox) and it would not let me do the "Save Link As" direct download trick. If anybody has the manual with the schematics for the 45 in PDF format let me know and I will trade you a Custom Embroidered CandCNC Logo Denim Machinest's Apron if you e-mail me the document. Contact me BEFORE you e-mail so I can give you an address with a larger inbox.

Thanks again

TOM caudle

www.CandCNC.com

-

03-08-2010, 02:55 PM #8

Heck Tom, I'll get you that doc for free.....it downloads just fine for me.....however it is a pretty big file.

Also.....you can call Hypertherm tech service and they will tell you the exact loactions to find plasma start (if using a hand torch) and Raw DC voltage .

Jim

-

03-09-2010, 08:22 PM #9

Just wanted to correct the info posted below in regards to proper connections for a Hypertherm Powermax45 for cnc and thc.

The raw DC voltage connections on the main board inside the unit are:

Positive is J21, Negative goes to J19 on most Powermax45's, however the 400 Volt CE units use J18 for the Negative raw voltage connection. Be carful attaching wirs to these points so that your ring terminals do not short to other traces on the PC board.

The Arc Transfer output connections (also know as "arc good", "machine motion", etc) are pins 12 and 14 (not 12 and 13 listed below) on the rear panel connector of the Powermax45.

The plasma start input connections are pins 3 and 4 on the rear panel connector. Note that pins 3 and 4 will not work as the plasma start input when the hand torch is attached to the Powermax45. There function works only with the machine torch for safety reasons.....the hand torch has a trigger switch on the handle.

All of these connections can be found in the Powermax45 service manual available for download from www.hypertherm.com

Jim Colt

[QUOTE=Bigtoy302;744682]1- goes to j21 on the main board inside the unit.

2- goes to j17 on the main board inside the unit.

3- goes to pin 12 or 13 on the rear connector on the machine.

4- goes to pin 12 or 13 on the rear connector on the machine.

Connect one to 12 and the other to 13

5- goes to 3 or 4 on the rear connector on the machine.

6- goes to 3 or 4 on the rear connector on the machine.

Connect one 3 and the other to 4.

QUOTE]

-

03-10-2010, 02:45 AM #10

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

[quote=jimcolt;746217]Just wanted to correct the info posted below in regards to proper connections for a Hypertherm Powermax45 for cnc and thc.

The raw DC voltage connections on the main board inside the unit are:

Positive is J21, Negative goes to J19 on most Powermax45's, however the 400 Volt CE units use J18 for the Negative raw voltage connection. Be carful attaching wirs to these points so that your ring terminals do not short to other traces on the PC board.

The Arc Transfer output connections (also know as "arc good", "machine motion", etc) are pins 12 and 14 (not 12 and 13 listed below) on the rear panel connector of the Powermax45.

The plasma start input connections are pins 3 and 4 on the rear panel connector. Note that pins 3 and 4 will not work as the plasma start input when the hand torch is attached to the Powermax45. There function works only with the machine torch for safety reasons.....the hand torch has a trigger switch on the handle.

All of these connections can be found in the Powermax45 service manual available for download from www.hypertherm.com

Jim Colt

Ya, that's what I meant. I must of had a dyslexic moment. I would edit the post but for some reason it will not let me.

-

03-15-2010, 02:32 AM #11

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 0

Any one know where to get a connector for the Powermax 45 interface. Is there a Digikey part # ? Ive jus got wires pushed in for now.

-

03-15-2010, 02:52 AM #12

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

06-02-2010, 09:41 PM #13

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 1

PLASMA BUILD NEED INFO

PLASMA BUILD NEED INFO

I AM BUILDING PLASMA TABLE 4X4 OR 5X5...I WAS PLANNING TO BUY 600 OZ STEPPER KIT WITH THC FROM CANCNC SOME 1600 BUCKS OR SO...BUT I GOT TO THINKING SINCE I GOOD WITH ELECTONICS AND FULLY EQUIPPED BUY WHAT I NEED MAYBE...

MY QUESTION::::: IS IT REALLY WORTH IT IN TIME ???...OR SIMPLY BUY WHAT THEY HAVE READY TO GO AND IS IT WORTH IN COST AND FUNCTION ???

THAT IS MY QUESTION ...THANKS...

-

06-02-2010, 11:15 PM #14

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

You probably should start your own thread on the subject.

In my opinion CandCNC.com products are very good, plus you have warranty & support.

If you take a long hard look at what all you get in the CandCNC kit then do the best you can to buy comparable components such as.

Power Supply with = voltage & amps

Gecko quality & reputation drivers

600 oz in hybrid steppers

Digital THC

All the wire you need to connect steppers + plugs

Quality project box to install everything into

Micro switches & wire

BOB & other interface boards + computer cables

Mach3 license

I'm sure I have forgot some of what is in the kit. You still have to wire everything together, test, diagnose etc.

There are lots of very fine examples here on the zone of electronics purchased individually & installed in a variety of different cabinets. take a look at some of those to get some idea of just how much primary wire it's going to take & how many connections you will have to make.

In my case I was a total newby when I started & didn't know a driver from a break out board. So it was a no brainer for me to choose something already put together. Now that I have been through a build & have read/studied countless hours on the subject, I could probably build from components. But I doubt I'd find the savings in money versus time spent worth it because I can get several $s per hr. running the table for hire.

If it's going to be a pure hobby & you don't expect to do jobs for hire, Then the do-it-yourself method becomes more attractive. If you are going to work the table & have any work waiting on your table it will be easy pay for the pre assembled electronics kit.

Just take your time, research it completely & decide for yourself which is better for you. Either way you can count on help from here on the zone.

NeilIf it works.....Don't fix it!

-

06-03-2010, 06:00 AM #15

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 68

If you look at my thread in the Precision Plasma sub-forum, you'll see I went with what you're talking about. I didn't want to tinker around with something like controls (I have built several CNC machines using the parts only method), and the inside build quality is very nice. The only issue I had with CandCNC is when I asked for a status of my order and I couldn't get a time frame of when it would ship. It did ship within the original estimate or near to it, and the quality is great. The kits are built to order, which can be a disadvantage to some. If you do decide to go with the CandCNC kit, order it as soon as possible if you plan to have other items to wait on. My project worked out well because I ordered the Gantry Kit, then the CandCNC. The Gantry arrived to me in under two weeks, and the CandCNC kit in 3-4 weeks, right as I was finishing up collecting most of the parts. I began table fabrication, and had all of the bits and pieces available to me as needed. I've been really pleased, but had I had everything ready to go and just needed control, waiting 3 weeks or so would be tough. Plan accordingly, but thus far CandCNC seems like a great bang for the buck. You can tell Tom thought things through, and it's not a mess of wires inside. It looks professionally made and I don't think you could ask for better considering the price.

-

06-03-2010, 03:51 PM #16

On top of that...Tom seems to be very willing to offer advice and support with the use of his products. If you have a lot of time to build from scratch....then that is good.....however the candcnc products are excellent quality and will save time....ultimately saving money in my book.

Jim Colt

-

06-03-2010, 05:09 PM #17

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

Thanks Jim. I spend a larger portion of my support time helping customers learn how to use the equipment than I do actual troubleshooting electronics problems. It's important to know that only part of the whole CNC cutting thing is hardware. A lot of builders are frustrated to find that the software, setup and use of plasma presents (sometimes) a larger challenge than doing the actual mechanical build. From the outside, plasma cutting looks simple. In reality it's harder than 2.5D router cutting. There is also a misconception that all of the CNC stuff is "standardized" (kinda like the plug-n-play PC cards are now) and you can just buy stuff and mix and match. It's not easy even if you know what you are doing.

TOM caudle

www.CandCNC.com

-

06-03-2010, 05:13 PM #18

If the plasma torch worked more like an endmill....then life would be easier! A lot of extra parameters to deal with!

Jim

-

06-03-2010, 05:59 PM #19

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

-

06-09-2010, 10:27 PM #20

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

I use Ox/fuel & there are more variables there than anyone other than a user could imagine also.

From the outside it looks simple. However very slight adjustments of cut height, regulator adjustments, feed etc. can make huge differences in cut finish & dross/slag remaining or not to the underside.

There is literally 1000's of combinations. The only way to learn it is hands on too.

With ox/fuel & I'm sure at least to a certain extent with plasma, you can tell a lot about what is going on by the sound. Sometimes more than sight.If it works.....Don't fix it!

Similar Threads

-

Hand torch to machine torch

By matttargett4 in forum Hypertherm PlasmaReplies: 10Last Post: 06-01-2010, 09:37 PM -

Hypertherm powermax 1000 and machine torch

By Mongkol in forum Waterjet General TopicsReplies: 3Last Post: 06-22-2008, 06:57 AM -

Different between hand torch& machine torch

By ltran2000 in forum Waterjet General TopicsReplies: 7Last Post: 03-02-2008, 04:19 PM -

Anyone interested in buying a powermax 1000 with machine torch, in vgc?

By Apples in forum Waterjet General TopicsReplies: 1Last Post: 12-27-2006, 09:54 PM -

Torch Height Control for PowerMax 1000

By barnon in forum Mach Plasma / LaserReplies: 2Last Post: 08-12-2006, 05:30 AM

Reply With Quote

Reply With Quote