Well, I've finally managed to get a lathe at home!

To compliment my little Sherline mill, I've paired it with a Sherline lathe, which I'll be converting to a CNC machine.

For now, it's a basic "CNC Ready" lathe (thrust bearings on the leadscrews, and motor mounts already fitted from the factory), a pair of stepper motors, and a pile of goodies.

One of the first troubles was this crunched power supply. The box arrived via our fine postal service, in a rather sad state. Accordion'ed for most of it's length, no single panel of the box was undamaged, and a rather large hole had been covered by some randomly-applied packing tape. Most of the contents were ok, except for the 48v power supply.

Luckily, there was a lot of crush-space between the chassis and circuit board... I never thought I'd repair a power supply with a hammer...

The supplier, KelingCNC, was ok with my disassembling it and 'repairs', and say they'll replace it if it doesn't work.

I've already smoke-tested it... it works just fine.

Results 1 to 20 of 23

-

03-08-2010, 05:12 AM #1

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Yet another Sherline lathe thread

http://www.youtube.com/user/vlmarshall

Yet another Sherline lathe thread

http://www.youtube.com/user/vlmarshall

-

03-08-2010, 05:13 AM #2

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

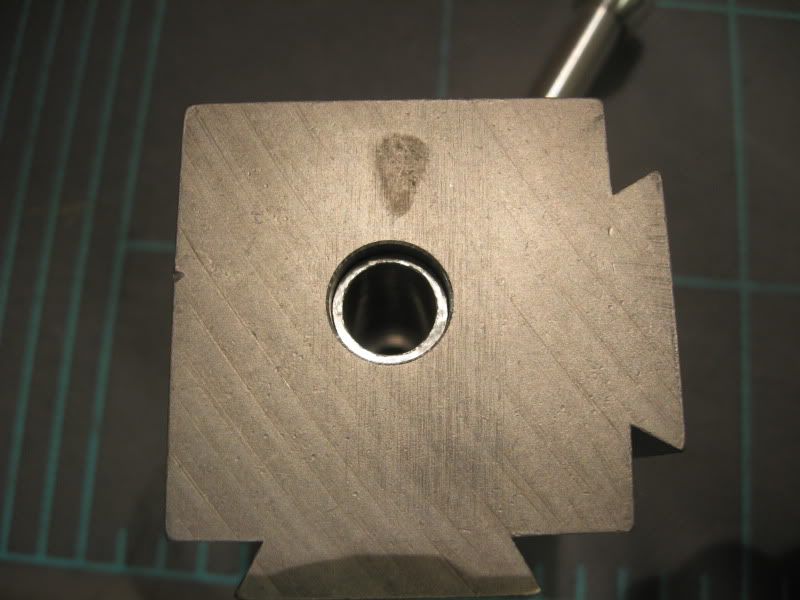

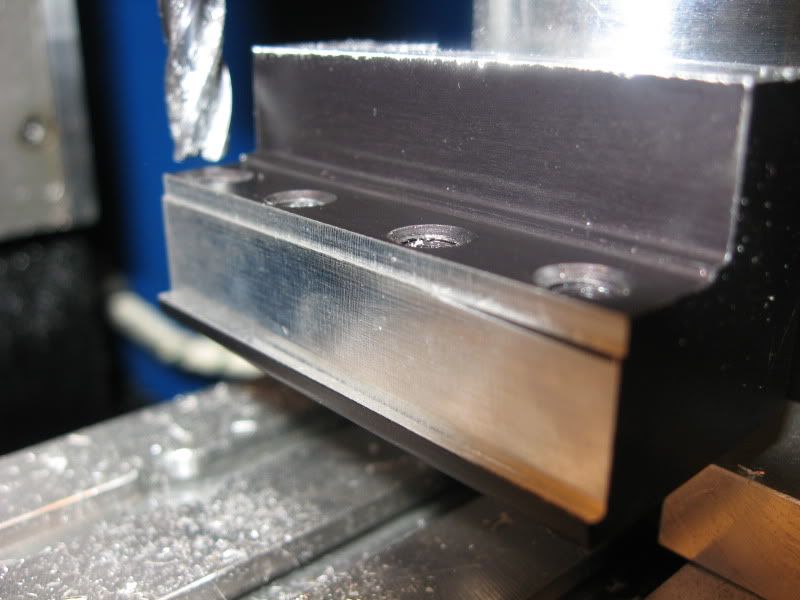

Next up, the little toolpost from A2ZCNC. All aluminum and Sherline sized, this QCTP falls somewhere between building my own, and buying that Aloris I've always wanted.

Not happy with the chattery finish on the locking cam and center post, I couldn't resist cleaning up the finish on both.

Before:

After:

The locking lever is next. I should have cleaned up that off-center center hole while I was at it. *

The BOTTOM of this toolpost was not machined, but left as-sawn! It also wasn't square to the dovetails, cleaning it up took almost .020"

While I was facing the 'post body, I skimmed the two non-dovetail sides, as they were both unmachined raw stock finish, and I'll be re-anodizing the body anyway, since almost every edge on the toolpost was not deburred after machining.

Skimming .020" off the bottom of the toolpost caused the tool holders to run out of adjustment when using 1/4" tools, so I skimmed a bit off of the holders, as well.

The slot for the parting tool is not cut straight, and because it's been machined in YET ANOTHER raw-stock surface, the slightly undersize material causes the slot to fade away to almost nothing at one end. Either that or the burr they left on the dovetail side caused the part to sit incorrectly for machining.

Yet another part for the anodizing bath...http://www.youtube.com/user/vlmarshall

-

03-08-2010, 05:19 AM #3

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

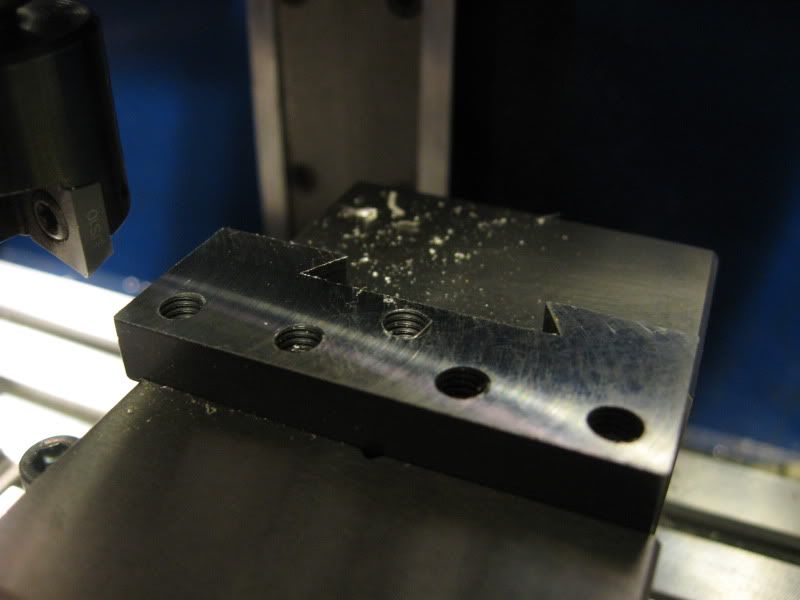

To rework that parting tool holder, I couldn't just throw it in a vise, and hack at the tool's seating surface, because none of the outer surfaces of the holder are squared up.

So, I set up the toolpost in my mill, and locked the holder into it's working position.

The first pass should give you an idea of how far out this thing was.

After a few passes, I'd gone in far enough to make the 'shelf' at the bottom the full width of the parting blade, so I cut the step at the top and called it "done".

Not a bad finish for cheap online endmills. http://www.youtube.com/user/vlmarshall

http://www.youtube.com/user/vlmarshall

-

03-08-2010, 05:22 AM #4

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

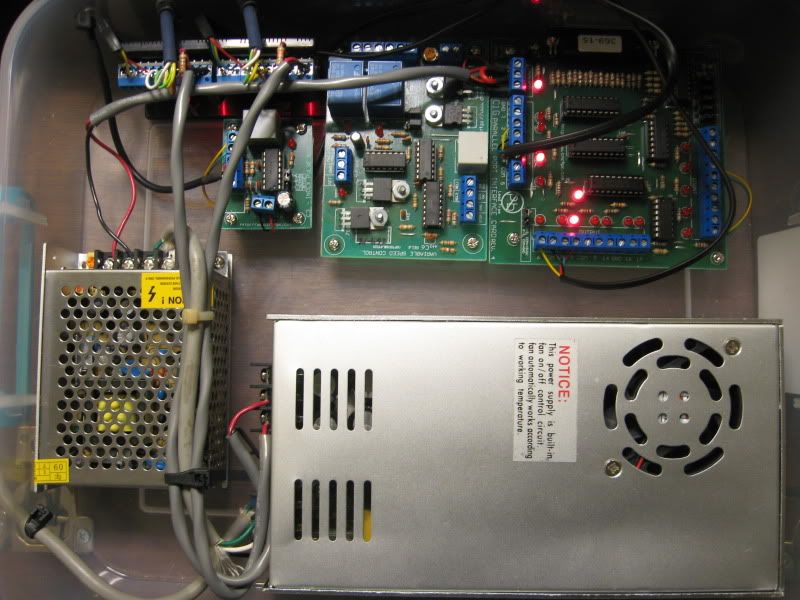

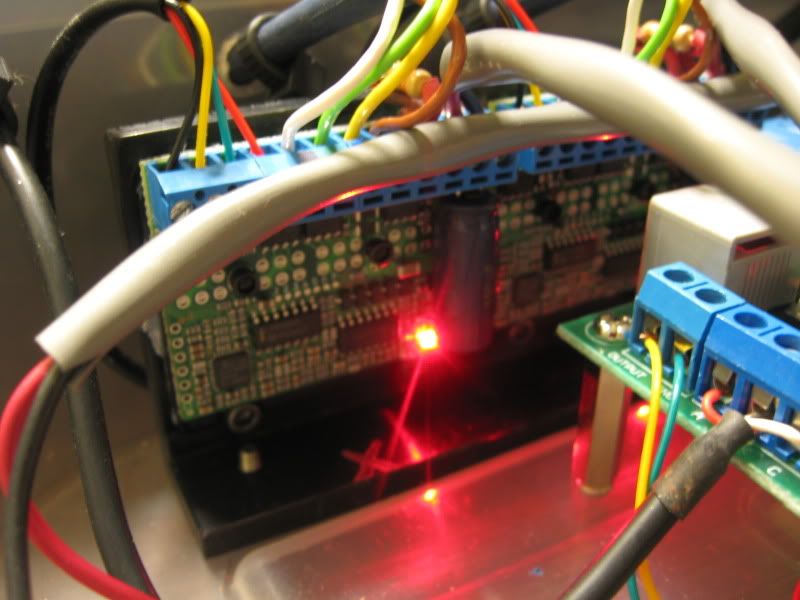

All of the electronics are tucked away in a plastic tub, at least for now.

There's my slightly wrinkly power supply, after some hammerwork on the case.

I just want to mention again how helpful KelingCNC was; I was getting almost instant email replies from them, probably 4 or 5 each way between us, and they were ok with me opening the power supply to check for board damage and to straighten the case. Everything was fine, the board had a bit of curl to it, but no damage. I got my parts, Keling didn't have to replace them, and the USPS got to take out their frustrations on the package in transit.

Gecko G251's... SO much better than the old Xylotex in my mill.

http://www.youtube.com/user/vlmarshall

http://www.youtube.com/user/vlmarshall

-

03-08-2010, 05:25 AM #5

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Today I got the software-controlled spindle working. This task caused me much trouble a year ago when I tried it on the mill, only to burn out my mill's motor controller. Tomorrow evening, I'll add a "Manual/Off/Computer" toggle switch to the Sherline's control box, neaten up the rest of the wiring, and calibrate the speed controller, if I can borrow a tachometer from work.

The last obstacle is the spindle index pulse...http://www.youtube.com/user/vlmarshall

-

03-09-2010, 11:44 AM #6

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Well, with the tach from work, I was able to tune the speed control to within 10 RPM of commanded (no-load) speed, through the 0-3000RPM range.

Now, I'm hoping to find someone who can help me set up EMC like Mach's High/Low range belt selection... and get EMC to see the spindle index pulse signal from the CNC4PC card I've got wired up.

This is fun stuff.http://www.youtube.com/user/vlmarshall

-

03-09-2010, 04:55 PM #7

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

sweet! thats a really clean electrical box mate!

I have not been happy with my a2z products... but thats pretty weak how you got that kit.

can't wait for more updates

sub'd

-

03-09-2010, 06:20 PM #8

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

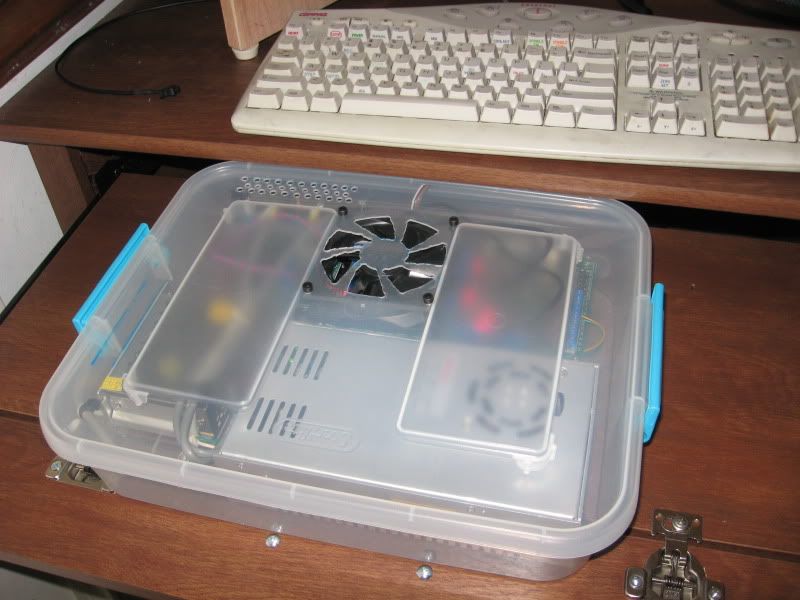

Thanks! The "clean" electrical box is just a plastic tub with holes poked in it. I'll post a better photo of it tonight, you probably won't be as impressed.

The first things I got from A2Z were a pair of endmill holders for my Sherline mill, one of them was nearly perfect, the other ran out a few thousandths. I figured it was just a mistake, and A2Z's owner pointed out in an email how to get it running true by sanding the mating face. It worked great, so with this toolpost for the lathe I ordered 6 more endmill holders.

Well, after examining this new batch, I realize that the first one that had problems wasn't the oddball of the bunch. I've spent 4 or 5 hours truing these up, but some of them can't be fixed; the bores aren't out of line, they're just not concentric to the threads. These things should be bored in the same setup as the threadcutting and mounting face, but it looks like they're made in batches of blank holders, and bored to endmill size in a later step.

I emailed A2Z about my complaints when I got this stuff, but didn't get a reply... probably because I wasn't asking for anything, just venting some dissatisfaction.

Ah well.http://www.youtube.com/user/vlmarshall

-

03-09-2010, 11:06 PM #9

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

See, nothing special here... just a plastic tub full of goodies. There's still a ribbon cable I need to run properly, from the speed controller to the motor driver. It's currently just trapped under the lid.

At first I was running this stuff with no lid while testing, but I've added the lid and fan, and now everything runs a lot cooler, tucked away in the keyboard drawer of that desk. I'm really happy with it.http://www.youtube.com/user/vlmarshall

-

03-10-2010, 12:07 AM #10

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

i have my vfd mounted the same way

i think its a really neat solution for how well it works and for how little it costs!

i think its a really neat solution for how well it works and for how little it costs!

-

03-10-2010, 12:33 AM #11

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Yeah, I'm really envious of you and that VFD, too.

While shopping for enclosures, everything I found was a few hundred bucks, for "real" enclosures... ok, a circuit breaker panel...no, $75 for that. Maybe a toolbox... $40-$50, ugh. Fine, I'll go with the $4 plastic Wal-Mart tub.

I'm not liking the board I have the lathe mounted on. Noisy.http://www.youtube.com/user/vlmarshall

-

03-12-2010, 01:49 AM #12

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Ugh. I can't figure out how to get EMC to do anything with the spindle index pulse.

Using the HALmeter in EMC, I can see the index pin (pin 13) flipping between True and False, as well as the input called "Spindle-Index"... but a G33 command just sits there waiting.http://www.youtube.com/user/vlmarshall

-

03-14-2010, 12:55 PM #13

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Progress! "Andypugh" on the IRC help channel for EMC has been a LOT of help... it's actually moving with the index pulse now, although I can see where a second encoder with more pulses would greatly improve accuracy.

Still, after weeks of frustration and no answers, I'm finally getting somewhere.

The Sample threading program that comes with EMC was pretty rough, but by matching the spindle speed and feedrate I was able to get good performance out of it.

Here's a (long, boring) video of my first singlepoint threadcutting with this lathe.

[ame="http://www.youtube.com/watch?v=C8zwXztmpEc"]YouTube- CNC Sherline Lathe Threading test cut[/ame]

The trick, thanks again, Andy, was to "connect" both the spindle index and encoder phase a (non-existant, really) to each other in the HAL file. At first, with the example program (using G33), movement was uneven, running along the part in surges, with each sweep of the index pulse. I was feeling certain I'd need a second encoder, but sped up the spindle RPM anyway, just as an experiment. It was MUCH smoother, so I decided to run this test cut in brass, properly matching the programmed feedrate... and it worked.

Not only did it work, but with the Gecko drives and 381in/oz motors, rapids are sure and quick enough to get out of the part at the end of the thread without the need for a relief groove.

Man, I'm happy. http://www.youtube.com/user/vlmarshall

http://www.youtube.com/user/vlmarshall

-

03-15-2010, 01:18 AM #14

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

neat!

it always amazed me a lathe can find the threads again... i imagine only the slightest error would throw it off.

-

03-18-2010, 12:28 AM #15

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

-

http://www.youtube.com/user/vlmarshall

-

03-18-2010, 12:34 AM #16

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Speaking of "Slightest Error".... When the EMC developers wrote this demo program, I guess they had a 30degree turning tool in mind, the one I used certainly didn't fit.

Oops.

[ame="http://www.youtube.com/watch?v=LDOWhg4R8a0"]YouTube- CNC Sherline lathe and the wrong turning tool.[/ame]http://www.youtube.com/user/vlmarshall

-

03-19-2010, 03:12 AM #17

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey mate that video is 'private'

-

03-19-2010, 09:05 AM #18

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

Oops. Thanks, Teyber!

http://www.youtube.com/user/vlmarshall

-

10-08-2010, 04:43 PM #19

Member

Member

- Join Date

- Feb 2004

- Posts

- 1311

Hi, I've been reading your Sherline Lathe build thread. I converted a Seig mini mill to CNC last year so I have some experience (I think!). I just acquired a Sherline lathe that was CNC'd about 6 years ago. It works fine but I want to add spindle speed control and especially an index pulse so I can start doing some threading. If you don't mind sharing some details, I'd like to hear what you did:

1) what's required to software control the spindle

2) how did you wire the manual/off/computer switch in the Sherline

3) what's required (hardware side, I use Mach3 and know how to handle the pulse in software) for the index pulse

Thanks in advance,

MichaelReelsmith, Angling Historian, and Author of "The Reelsmith's Primer"

www.EclecticAngler.com | www.ReelLinesPress.com

-

08-13-2011, 06:43 PM #20

While I know this post is DATED. I was hoping some one could guide me thru setting up the pulse card on a Sherline spindle setup. I am using the sherline spindle for a lather Im working on and want to add threading to it. So if anyone knows of a walk thru let me know.

Similar Threads

-

Anybody thread milling on a Sherline mill with Mach3?

By mpolcyn in forum Mach Software (ArtSoft software)Replies: 5Last Post: 06-13-2014, 02:41 PM -

Sherline Lathe & Bob Cad-Cam v23

By tip in forum Mach LatheReplies: 1Last Post: 08-09-2009, 01:47 AM -

New Sherline lathe! I'm ecstatic!

By MechanoMan in forum Mini LatheReplies: 19Last Post: 06-19-2009, 04:29 AM -

7x CNC Lathe or sherline?

By Jason23 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 09-10-2008, 06:08 AM -

What Sherline Lathe Accessories To Buy And When?

By Too_Many_Tools in forum Mini LatheReplies: 6Last Post: 10-11-2007, 05:46 AM

Reply With Quote

Reply With Quote