We had a salesman talk our guy out of Vactra 2 and into this stuff called STAY-VIS...now the F#cking Z shows chatter marks onthe boxed ways and it looks like it isnt oiling....anyone has similar issues?

Thread: Z not oiling!!!!

Results 1 to 12 of 12

-

04-24-2005, 06:25 PM #1

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Z not oiling!!!!

-

04-24-2005, 06:41 PM #2

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

we even have have a rubber sheild for the coolant ..WTF

-

04-24-2005, 06:42 PM #3

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 564

what is the "weight" of the 2 oils in comparison?

If the newer one is "lighter" you may need to apply it more often.

Also what type of "lube" system is it? ie manual,pneumatic ect......

You could block all other lines except the ones to "Z" and manually keep pushing the lube through until it comes out to make sure it is getting through.menomana

-

04-24-2005, 06:53 PM #4

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Its a standard pnuematic oiling system for fadal's.....it reads 120psi at the oiler. Vactra 2 substitues

Febis K 68, Tonna ,Oil T68, Way Lube 80, Way Lube 68...this Sta-vis is a ISO 68 (ASTM315) and it should work...

-

04-24-2005, 07:16 PM #5

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

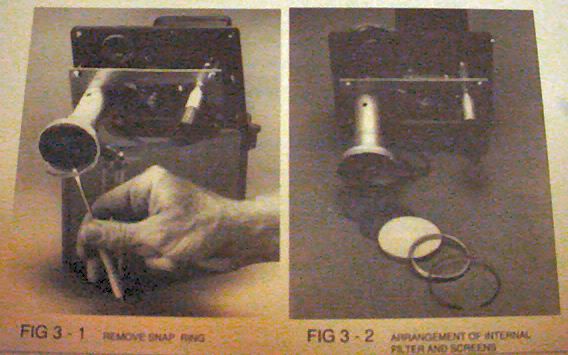

Looking at it at first I thought it was the MAC air valve...these are **** valves if you dont run synthetic air oil they freeze up pretty fast...but are rebuildable. Then I saw the manual and the cleaning the filter.....oh nooooo we havent cleaned the filter in years!!!! In YEARS!!!!!

here are the pics of the oiler and the filter change in the manual

-

04-24-2005, 08:40 PM #6

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 564

If your getting oil to other parts of machine, I would assume the pump is working fine.

You could have a broken lube line that is scavaging all the oil, and therefore never makes it to the z axis.

How often is the unit cycling oil to the axis? maybe the frequency needs to be increased?menomana

-

04-24-2005, 08:53 PM #7

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Is their anyone who knows about this oiling?

trubleshtr..I can tell you arent familiar with this type of system. If any leaks are there the system will drain itself and not hold pressure. Z axis movement is constant in a cnc.

-

04-24-2005, 09:29 PM #8

That looks like a standard Bijur system, what you should have is metering points at the end of each lube point, they look at first like a ordinary 1/8" fitting, but each point has them and I would recommend changing them at least every 5 to 6 yrs for a machine that is run constantly, the hex fitting has a FSA or CSA etc followed by an appature number 0,00,1,2, etc.

They have fine filters in them and usually it is not worth trying to blow them out or clean them. these systems BTW can attain pressures in excess of 20lbs.

Usually these lube systems are the most neglegted.

If you open one up and put it back, this point will get all the oil to the detrement of all the other points.

AlCNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

04-25-2005, 12:59 AM #9

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 564

Right! Originally Posted by carbidecraters

Originally Posted by carbidecraters

So

1.if your system drains go look for a big puddle of oil where there should'nt be one.

2.If your system uses end of line pressure switches, and are set-up correctly you would be getting lube alarms for pressure.Oil will flow to the path of least resistance.......

Seeming as neither of these seems to be your problem,

look at anything between pump and linear rail.ie.

Metering valves not working or hyd. locked,

kinked lines.

dirt plugging the lines, from when you switched over to the new oil.

Perhaps this new oil does not have the friction capabilites your old oil did?

If it were me, I would un-do the fittings and fire the pump, does oil come out???yes...then mabey it's not enough, No well then start back tracking towards pump.

Just trying to help you out.

Further more, I do know these systems quit well. In fact If you need to buy one I'll be more than happy to sell you a re-furbished unit.menomana

-

04-25-2005, 05:32 PM #10

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Dont take it personal please...probly hard not too since your in the field but I have to pick apart your post

ISO 68 (astm 315) you may have missed that part.Perhaps this new oil does not have the friction capabilites your old oil did?

You cant know these systems that well if you posted that.1.if your system drains go look for a big puddle of oil where there should'nt be one.

Your posts are helpfull but this isnt a issue where general tech help would have benefitted the situation....well except for our stupidity on the not changing the filter...

I will shut up now

-

05-13-2005, 06:19 PM #11

Registered

Registered

- Join Date

- May 2005

- Posts

- 7

unfortunately your ways look fairly normal for a Fadal with any kind of age & usage on it but Fadals are common to have problems with oiling.

The brand of oil seems to be an issue on these machines with some having more solids (parafin) in the oil this will precipitate out and plug the screen, the cartridge filter on the out side of the tank and also plug or render the injectors at each manifold useless.

Depending on the age of your machine the pressure gauge at the oiler should read from 200 to 350 lbs when cycling either on a 10 minute cycle or 4 minute cycle- again age and model affect this timing.

The most common oiling problems seem to be with X axis and usually don't get caught until the turcite is gone and the ways are corroded.

-

07-07-2005, 02:26 PM #12

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 167

I tried switching oil once. Just like your case it should of worked. Switched back and problem went away. The only other thought is that the gibbs are out of adjustment and that is cousing the head to "rock" as it moves. this will couse the ways to look like your picture. But I think it's the oil.

Reply With Quote

Reply With Quote