Hello all!

I've recently bought a Rabbit 40 /HX40A laser cutter/engraver and I've been getting to know how it works and how to fix those little quirky problems. Unfortunately after going along absolutely fine earlier this evening, and almost managing to cut my first 'real' acrylic piece, it all seems to have gone a bit wonky.

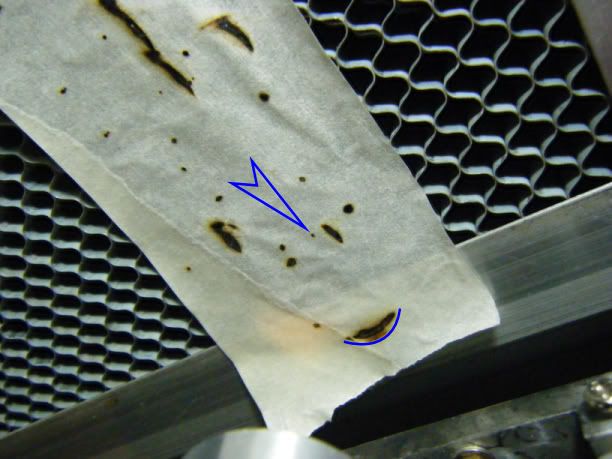

It seemed to stop cutting as strongly so I got my trusty bit of masking tape out (as suggested in the setup video - end of [ame="http://www.youtube.com/watch?v=UPfQjAwz54M"]YouTube- HX40A/40B 2[/ame] and very start of [ame="http://www.youtube.com/watch?v=vaj1HcILwPk"]YouTube- HX40A/40B3[/ame]) to test the laser and it's producing a pattern like this:

Normally of course it'd produce a tiny dot so the great big curve at the bottom and the practically non-existent dot are not right at all. I've taken the lens out and cleaned it, taken the mirror out and cleaned it, checked the alignment on the other mirrors (not great but then what am I expecting!).

Any suggestions?

Any help very much appreciated! I was so close to getting going :S

Becki

Thread: What have I done wrong?

Results 1 to 15 of 15

-

03-14-2010, 09:50 PM #1

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 4

What have I done wrong?

-

03-15-2010, 08:56 AM #2

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 146

Hello (there seems to be more and more of us british folk using lasers these days)

I dont think its a major problem to fix, Someone may correct me but, it looks like an alignment issue where the beam is reflecting somewhere inside the lens holder and diffusing the beam into that arc shape.

Can you double check the alignment of the mirrors (to the mm) and check the alignment over the four corners of the cutting area. If the beam is better in one area than in another then again it is a problem with the alignment of the beam as it enters the lens holder.

I had similar problems and it took a while to get the exact adjustment.rabbit / ls3040

-

03-15-2010, 02:48 PM #3

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 1258

I agree geekinesis, it is most likely an alignment issue.

I would guess it's at the lens / holder end but check the first mirror near the tube is centered and then the next with the axis at both ends and so on... at the final 'head' end the beam should be centered on the hole so that it hits the mirror and is reflected into the center of the lens. If the lens isn't sitting in the holder correctly it could cause the problem too.

Zax. (a 10yr Texan, but 100% Brit!)

-

03-15-2010, 11:56 PM #4

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 4

Hi guys,

Thanks for your help with this, and for being gentle with a newbie! Nice to meet some fellow Brits

This is so annoying cos it was all pretty much aligned and working and everything. Still, at least I'll hopefully know what to do if it happens again.

First mirror (the one nearest the laser tube itself) is fine, pretty much centred.

However the second mirror is where it gets interesting. I've spent ages this evening getting the beam to hit almost central with much twiddling and adjusting of the weird screw system. The beam hits central when the 2nd mirror is near the 1st one but the it moves up when I move the 2nd mirror assembly away. What can I do about this? Is it to do with the top-bottom alignment of the first mirror? Also I managed to get some tiny dots of glue on the mirror from a masking tape mini fireball when I was testing. As they won't come off I guess I'm going to need a new mirror. Know of any good stockists?

Having got it near enough on the 2nd mirror I turned my attention to the lens and mirror, starting off with shooting a beam at masking tape on the mirror assembly - and the beam was so far over the top it didn't even touch the tape! When I brought the 3rd mirror closer to the 2nd one it was low enough so as to actually show on the masking tape but nowhere near the hole in the side of the mirror assembly. I seem to have gone from having weird cutting to no cutting at all in my attempts to fix it!

I wish I could just wave a magic wand and have it work again

Thanks again

Becki

-

03-15-2010, 11:59 PM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 123

Focus problems.

Focus problems.

Hi Becki

as the others have said it is most likely an alignment problem.

a problem i experienced with the masking tape/ cardboard alignment method is that when i was testing the final mirror alignment there is nothing to stop flakes of burnt tape/cardboard entering the head assembly and settling on the lens.

in addition to the beam alignment it might be worth making sure there is no ash lying on top of the focus lens?

regards

KPB

(unrelated - quite amusing in the video 40B 3 where the guy gets the machine all powered up and then seems to immediately dive in and grab the HV connection with bare hands, then proceed to cut the tape off the tube connection with what appears to be an improvised Glasgow prison weapon. )

)

-

03-16-2010, 12:06 AM #6

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 123

removing glue on mirror

Becki - in your post you also mention glue spots on the mirror -

isopropy alcohol should remove it - you can get it from Maplin, or i think Jessops camera shop also sells it. jessops will also sell decent lens cloths.

regards

-

03-17-2010, 12:50 AM #7

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 1258

Becki, adjusting the alignment isn't difficult once you've figured out the method and got the hang of those terrible adjustment screws.

The key is getting the beam parallel to the ways (axis), which is more important than hitting the mirror in the center - although ideally you achieve both.

Since the beam moves up as you get further from the previous mirror, the beam is angled upwards so you need to adjust it down to parallel. Doing so may mean the beam is now not perfectly centered but it will still work just fine. Just ensure it isn't too close to the edge or you'll lose power.

Zax.

-

03-17-2010, 07:19 AM #8

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 146

Setting up the beam alignment is frustrating and seems neverending when you are doing it.

Also I hope you are wearing some safety glasses with the cover of the machine open.rabbit / ls3040

-

03-17-2010, 09:43 AM #9

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 96

Hello. I dont per say know the smaller cutter/engravers but i am factory trained by Trumph which makes large 3000 watt to 5000 watt laser cutters. I can tell you that beam alignment as stated by the others is critical and probably the culprit, however, never and i repeat never use isoprophyl alcohol on a lens or beam bending optic. Alcohol leaves a residue that you cant see but it is there. Will this work, yes, but the residue will cause your beam quality to go away much quicker and you will have to do lens and optic cleaning more frequently to maintain the same cut quality. You need to use a good grade Acetone. Acetones , if it is worth anything, will come with a residue ppm rating. The lower the rating the better the Acetone. You can get an organic lab grade for about 75.00 for a gallon. This may seem expensive but it takes very little to clean an optic so this gallon will last a long time. We ordered this size because we had so many lasers so you shouldn't have to get as much. Trust me, your optics will love you for it. If you have any copper optics in the telescope or the cutting head use Semichrome polish to clean the optic and then use the acetone to remove any residues. I can also tell you this, there is a right way and a wrong way to clean optics and in most cases poor cleaning technique is almost as detramental as not cleaning them at all. As i said, i realize this is not a large scale laser cutter but the optics are the same. I am certine that people will tell you they have been using alcohol for years and works fine but consult any leading optic manufacturer such as II-VI and the will absolutley verify this. Good luck lasers are an awesome machine.

-

03-17-2010, 03:21 PM #10

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 1258

-

03-17-2010, 03:32 PM #11

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 1258

Agreed.

The recommend process is a 2-stage clean, using >90% IPA followed by Acetone.

IPA alone will work for the optics on low power lasers but yes it does leave a residue (an invisible film). It does however remove certain contaminants better than Acetone.

For the record, I only use IPA but you may want to 'do as I say' rather than 'do as I do'.

but you may want to 'do as I say' rather than 'do as I do'.

Zax.

-

03-19-2010, 12:34 AM #12

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 4

Blimey, there have been a few replies since I last popped in! Thank you all for your comments and suggestions

I'm happy to report that I managed to get the beam aligned correctly. I worked my way round all of the mirrors adjusting for what seemed like ages but I managed to sort it in the end - I think the culprit was probably the slightly loose screws on the first mirror from when I was adjusting it before. The beam is actually finer and stronger than it was before which was very pleasing! And the practise etc at getting the beam realigned will stand me in good stead for if/when I need to do it again in the future.

The glue on the second mirror doesn't seem to be affecting it too badly at the moment but it's something to bear in mind and keep an eye on.

I close the lid when I'm actually testing the beam alignment (unlike the instruction video) and there are several different ways that I can be sure I'm not going to get lasered in the eye when the lid's open! What's the difference between safety glasses and normal glasses? Originally Posted by geekinesis

Originally Posted by geekinesis

Interesting to know - I had used isopropyl to clean smoke marks off one mirror but I will definitely look into getting some acetone instead. Originally Posted by CNCZILLA

Originally Posted by CNCZILLA

Thanks again for all your help guys! Thought you might want to see what I managed to make after all my efforts (although, assuming -perhaps wrongly - that you're all male, you might find it a little girly!):

Becki

-

03-19-2010, 03:43 PM #13

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 1258

Becki,

That's great news, and an excellent butterfly design too. Well done!

LASER safety glasses block out the wavelength of the laser they are rated for, or at least attenuate it to a safe power level. They are not required if you use the machine correctly, which it sounds like you do.

These small CO2 lasers are among the safest as the unfocused beam (if a mirror detached and directed the beam towards the operator) would not penetrate the Acrylic viewing window, and providing it has interlocks (which it should) the laser will be disabled when the cover is open.

Enjoy your newly aligned laser.

Zax.

-

03-20-2010, 08:05 AM #14

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 146

glad its all working out with the laser at last.

rabbit / ls3040

-

03-22-2010, 10:35 AM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 123

Success...

Also happy to hear that all is well.

and i must apologise for the bum steer regarding IPA.

i'm off to get myself some acetone! thanks CNCZILLA for the sound advice.

regards

KPB

Similar Threads

-

I sure I'm doing something wrong but what??

By dberrouard in forum Mach Software (ArtSoft software)Replies: 9Last Post: 01-16-2009, 12:35 PM -

What am I doing wrong?

By Rhinorider in forum Mach Software (ArtSoft software)Replies: 1Last Post: 01-12-2009, 05:29 AM -

Not sure what I'm doing wrong

By chuy in forum MastercamReplies: 4Last Post: 08-01-2007, 09:28 AM -

When everything goes wrong.

By ImanCarrot in forum MetalWork DiscussionReplies: 4Last Post: 04-24-2006, 03:42 AM -

anyone know what i am doing wrong

By pauluk in forum Digitizing and Laser DigitizingReplies: 14Last Post: 02-16-2006, 05:48 PM

Reply With Quote

Reply With Quote