Thread: 1x1.5m machine

Results 61 to 70 of 70

-

11-07-2011, 10:28 AM #61

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 87

-

11-07-2011, 03:47 PM #62

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Hi Stef,

Coming along nicely, Good choice changing that Z axis it will perform much better.

Before you start making chips I would cover the gaps down the side.! Amazing how much crap gets onto the screws and nut, it will also fill that cable chain in minutes.

-

11-07-2011, 03:51 PM #63

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 87

oh yes, i'll make sure a do that.

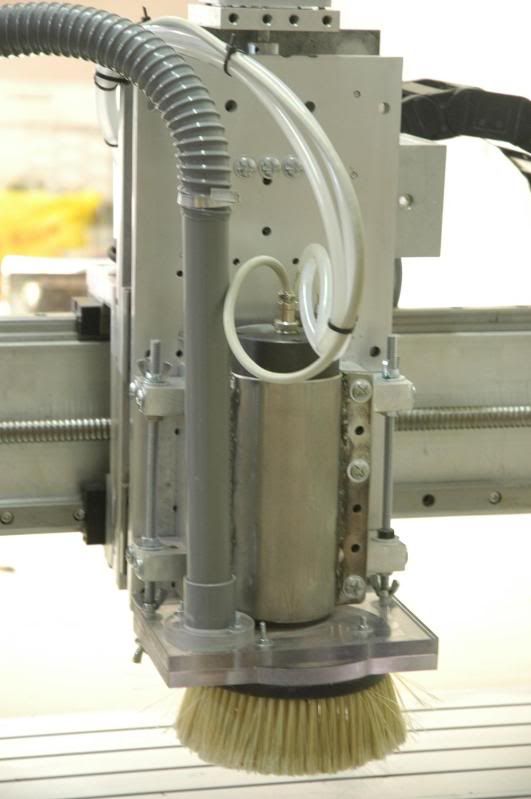

still a few things to do before cutting anything though. cooling needs a new pump (washing machine pumps are not powerfull enough), i need to attach a few cables, and sort out the cable chain.

-

11-07-2011, 04:09 PM #64

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Be carefull with the pump.!. . 2 main things to look for are Head height if pumping from a tank and duty cycle time. Duty time is often the thing that kills pumps and you need one that is rated close 100% as possible. . .These spindles don't need large flow just a nice continous one.

I used a fish tank pump with 2mtr head height, it's just died after nearly 3yrs so I'm happy with that. Now I have a 24V 7mtr head height pump bought from Ebay and it's working nicely.

-

11-08-2011, 02:54 AM #65

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 853

How long would the spindle run without cooling before trouble sets in? Would you go as far as putting a flow switch wired to the estop?

-

11-08-2011, 02:03 PM #66

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

No I wouldn't bother with a flow switch. They will run quite a long time before causing trouble.

Recently my pump failed and I cut several small 15-20min jobs without coolant flowing with out any trouble or sign of over heating. . . . Not something I would recommend but does show that they will handle pump failure for more than a few minutes without destroying them selfs.

-

02-07-2012, 03:22 PM #67

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 87

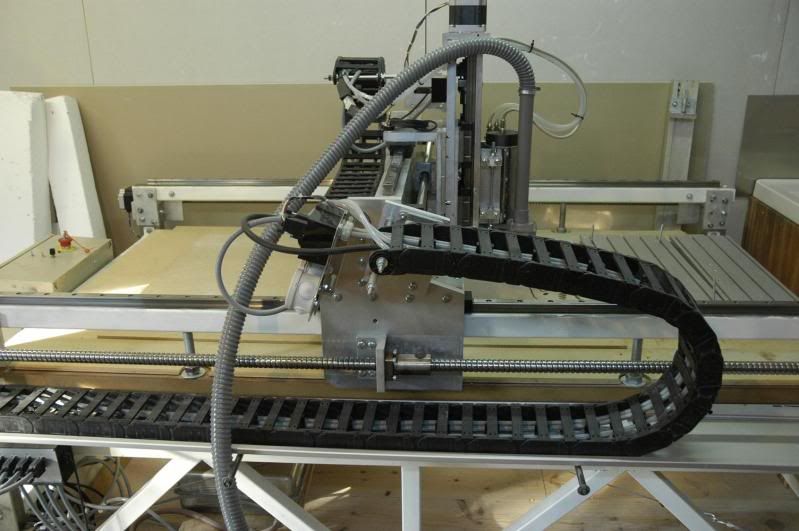

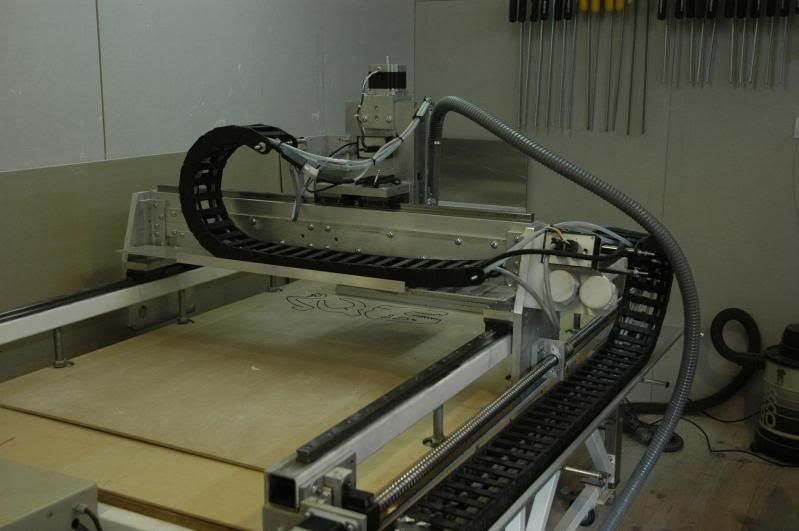

all done

I managed at least 5h of manchining with no problem whatsoever.

i am still on the washing machine pump, and no sign of heating on the spindle (the steppers though...they do get hot !)

almost finished my first mdf dynosaur, after going through one mill bit (well, it was turning the wrong way round !)

I am quite pleased with my dust collection attachement, it works a charm.

so far, cuts a very accurate and repeatable, exept in the z direction. i seem to struggle there, and i am undercutting most of the time (not going the full 6mm depth in the mdf)

something to think about...

-

02-07-2012, 04:23 PM #68

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Yipee nice to see it come alive Stef. . . . Bet the kids loved seeing it cut them dino's.

How hot are the Motor's.? They do get quite warm but shouldn't be burning hot.!

Try backing off the tuning slightly on the Z axis, I prefer to tune for acceleration and drop the velocity on the Z axis. . . . Just don't over do it.!

Pleased to see it working, do you have any special jobs planned of it.?

Edit: Just watched the video.!!. . . . Far far far too slow Stef crank it up. Knowing the strength of your machine then with a 6mm 2 flute cutter and 3mm Depth of cut 15000rpm you will easily cut MDF at 5mtr/min.

-

02-07-2012, 05:04 PM #69

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 87

cheers dean,

yes, as you can see, the z is already very slow..besides, if it starts missing steps, it would be on the journey upwards, so i would end up cutting too deep. but it's the other way round, i am cutting too shallow.

oh well, that should keep me busy !

no special job, just more jobs ! mostly kid stuff !

the motors are hot to the touch, a bit like a hot central heat radiator. you can leave your hand on it, but it feels pretty hot. But thats after a couple of hours work. i may tweak the current limit.

so far, i have been using a single flute 5mm bit. still working out the limits !

it seems to dull pretty rapidely though (4-5hours) or am i expecting too much ?

the first bit i used was a 4 blades helicoid cutter, but that was spining the wrong way round (dont ask !). so that ended up caked in MDF caramel after 2 mins.

the second one i tried was a double flute helicoid, which left a lot of fluff on the cuts.. i was runing out of mills, so i used the 5mm single flute router bit. that worked much better !

-

02-07-2012, 06:59 PM #70

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

That's quite normal after several hours use, great on days like today when it's -5 for warming the fingers. .Lol

Regards missing steps on Z axis then if it's doing it at this low speed then I would check for aliagnment and binding first before doing anything else.

Mdf is very hard on cutters but your low feeds n speeds will also be putting extra wear on the cutter.

I've just checked with G-wizzard and 5mm SF HSS cutter with 25mm protrusion from spindle calculated for MDF with best or least tool deflection comes out at.

DOC: 1mm

Feed: 6100mm/min

RPM: 20,000

Deflection: 0.0188mm

Same but with more DOC

@ DOC 2.5mm

Feed 5400mm/min

RPM: 17,700

Deflection 0.0489

So not exactly extreme stress when cutting deep.!

The same cutter but Carbide still at optimised deflection comes out at

DOC: 4.5mm

Feed: 4500mm/min

RPM 24,000

deflection: 0.0188

I prefer to use tool deflection for guide as it best ensures least stress on cutter and therefore reduces chances of snapping, Thou figures could easily be increased but at the cost of more tool deflection.

Obviously these figures are guides and don't take into account machine strength. Because your machine is so very close to mine in design then I know it will easly handle these DOC/feeds etc because mine does. Personaly in MDF I would cut deeper than these calc's show and take a bit more deflection.

Similar Threads

-

Another machine rigid tapping (stepper machine)

By samco in forum LinuxCNC (formerly EMC2)Replies: 11Last Post: 02-12-2019, 05:53 PM -

saleCNC laser engraving machine and CNC woodworking machine

By zhangrui1588 in forum Laser Engraving / Cutting Machine General TopicsReplies: 3Last Post: 05-08-2011, 09:54 PM -

Hardinge CBN Turning Machine with GE Fanuc Machine Model CS- 51, S.No. CL – 622 -BSP

By M.RISHIKESH in forum Hardinge LathesReplies: 1Last Post: 11-21-2009, 01:03 AM -

Deep Groove Taig machine would it be a good starter machine

By Fritzie15 in forum Taig Mills / LathesReplies: 0Last Post: 09-21-2007, 03:37 AM

Reply With Quote

Reply With Quote