I recently got a HF 8x12 lathe and wanted to get the lathemaster qctp. Unfortunately, they are sold out and not getting any new ones in till May or June. Their version seems to be the most popular for these lathes because it has modified tool holders for proper alignment. Instead, I found a new way of allowing the standard 100 series to fit so I ordered the standard AXA 100 series from LMS.

First, I machined the boss flat with the compound so it was all the same height. Next I drilled and tapped the existing hole where the boss was to fit the big bolt on the axa qctp. You need a 9/16- 18 tap. I picked one up at the local OSH. The tap specified a 33/64 drill. They didn't have that so I used an existing 1/2" drill.

After putting the qctp on the lathe for fitment, I found that the tool holder wouldn't go down enough for proper tool alignment. This is why some have used cut down tool holders or the LMS machined compound that is thinner where the qctp goes.

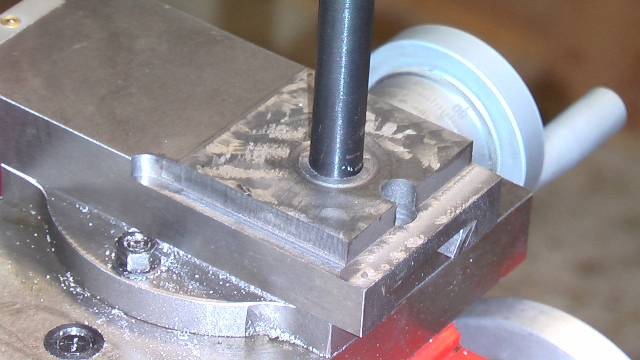

Instead, I machined 2 edges of the compound to allow the tool holder to be lowered to the proper height. It now allows a wide range of adjustment and alignment using standard lower cost tool holders while base of the compound retains its stock thickness and rigidity.

Here was the original machine work:

I found however that I couldn't rotate the qctp to align at the right angle for cutting threads so I made one more diagonal cut. Now I can align the tool properly for cutting threads etc.

Here are some pics:

Here it is with the compound at 30 degrees and aligned 90 degrees to the chuck with more room for adjustment available. As you can see you can move the tool holder over a much wider range vertically than stock and align it properly on the compound while still maintaining the stock compound thickness:

Next mods are dro and VFD!

Results 1 to 8 of 8

-

03-22-2010, 07:20 PM #1

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

HF 8x12 mod for standard AXA qctp

-

03-23-2010, 01:53 AM #2

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 27

Nice job, looks like that will be my next mod. Thanks.

-

03-23-2010, 05:27 PM #3

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 256

-

04-09-2010, 12:09 AM #4

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

HF 8x12 mod for standard AXA qctp

--------------------------------------------------------------------------------

I recently got a HF 8x12 lathe and wanted to get the lathemaster qctp. Unfortunately, they are sold out and not getting any new ones in till May or June. Their version seems to be the most popular for these lathes because it has modified tool holders for proper alignment. Instead, I found a new way of allowing the standard 100 series to fit so I ordered the standard AXA 100 series from LMS.

First, I machined the boss flat with the compound so it was all the same height. Next I drilled and tapped the existing hole where the boss was to fit the big bolt on the axa qctp. You need a 9/16- 18 tap. I picked one up at the local OSH. The tap specified a 33/64 drill. They didn't have that so I used an existing 1/2" drill.

After putting the qctp on the lathe for fitment, I found that the tool holder wouldn't go down enough for proper tool alignment. This is why some have used cut down tool holders or the LMS machined compound that is thinner where the qctp goes.

Instead, I machined 2 edges of the compound to allow the tool holder to be lowered to the proper height. It now allows a wide range of adjustment and alignment using standard lower cost tool holders while base of the compound retains its stock thickness and rigidity.

Here was the original machine work:

I found however that I couldn't rotate the qctp to align at the right angle for cutting threads so I made one more diagonal cut. Now I can align the tool properly for cutting threads etc.

Here are some pics:

Here it is with the compound at 30 degrees and aligned 90 degrees to the chuck with more room for adjustment available. As you can see you can move the tool holder over a much wider range vertically than stock and align it properly on the compound while still maintaining the stock compound thickness:

Next mods are dro and VFD!

MOD: please delete below duplicate post.

-

04-09-2010, 02:23 AM #5

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 27

An alternate approach

Little Machine Shop sells a ready-to-go, AXA-compatible compound rest top for the 8X14 lathe, $35.95, plus shipping:

http://www.littlemachineshop.com/pro...ory=1963256898

-

04-09-2010, 06:36 PM #6

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

I am a fan of lms and looked at their machined compound. You lose rigidity by machining the whole section down. If you look at my pic where the 9/16" shaft is coming out, It is already a bit thin. Machining it down more didn't make sense to me and it only took a couple of minutes to machine it anyway. You still have to do some work with the LMS version to tap the handle mounts and the 9/16" bolt so the lms version isn't true turn key anyway.

-

04-09-2010, 07:01 PM #7

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 27

>> If you look at my pic where the 9/16" shaft is coming out, It is already a bit thin.

Yes - I was thinking the same thing. Out of the three approaches, I think I like yours about the best - and the lathemaster approach (milling the bottom of every toolholder) the least.

I am partial to this lathe - and expect one to fall in my lap one day. Meanwhile I'll live vicariously - but keep the photos coming.

VFD you say? Excellent ....

-

04-09-2010, 07:36 PM #8

Member

Member

- Join Date

- Feb 2010

- Posts

- 0

I did the same on my 7 x, except I only machined the front edge that was not under the dove tail of the post. That needed to get the parting tool to work, but it is nice to have more range for the other tools as well.

Similar Threads

-

8x12 QCTP... Does this add up?

By forrest39 in forum Mini LatheReplies: 9Last Post: 01-31-2010, 06:35 AM -

HF 8x12 MOD (Bolt on QCTP)

By Dan S in forum Mini LatheReplies: 4Last Post: 05-25-2008, 10:51 PM -

anyone using a QCTP?

By dahui in forum Shopmaster/ShoptaskReplies: 0Last Post: 05-04-2006, 02:08 PM -

Another 8x12 mod - QCTP

By pjeran in forum Mini LatheReplies: 0Last Post: 04-22-2006, 05:43 AM -

Has anyone tried HF QCTP

By James04 in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 04-23-2003, 08:03 AM

Reply With Quote

Reply With Quote