There have been lots of threads, videos, and posts about the new high speed machining methods easily programmable using the currently available CAM packages. I don't remenber the correct term for the process but I think it starts with a T and amounts to the tool moving into the material with a sweeping arch. If one is cutting a slot the tool makes the arch returns to the start point and repeats the process.

To the ill informed it looks like the whole idea here is getting the tool into the material on the correct trajectory. I have a project coming up where I have to cut .125 off both sides of 22 1/2" thick 314 bars each 43 inches long. I'm of course interested in opinions on feeds, speeds, coolant, etc. I plan on doing it with the bottom of a 1" 3 flute insert mill. My question is would it be advantageous to ramp into the side of the bar using an arch as previously described to create a wedge of partially machined area. Then, set up the insert mill to run the length of the bar gradually chewing into the previously described ramp. In the first case we did the T trick with the tool path, in the second case we let the material do the T trick on the cutter. Does that make any sense? I've attached drawings because it probablu does not.

If you are wondering this is mostly an academic exercise to improve tool life where it would certainly be cheaper to simply buy a couple extra inserts. Geof, this is the kind of thing you usually like to play with

Results 1 to 4 of 4

-

04-26-2010, 07:35 PM #1

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 447

maybe too much information on SS 314

-

04-26-2010, 09:43 PM #2

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Hi Vern!

That "T" word you're looking for is "Trochoidal Milling" in all likelihood.

The high speed toolpath algorithms are not all Trochoidal, but they all involve looping the cutter to clear material instead of just diving straight in. They're doing this for two reasons.

First, cutter engagement in corners radically changes the stress on the cutters. So if instead of plowing straight into the corner, you take a series of smaller radius loops, you can clear a lot of that and reduce the amount of engagement:

If you consider cutting straight along a wall and the amount of material the cutter is embedded in versus when the cutter enters a corner, you will see there is a lot more. Consider the picture from above:

The corner exposes the cutter to about 2x as much stock as moving along the wall. Moreover, consider the fraction of the circle when the cutter isn't doing any cutting as cooling time for it to recover before going back into the material. If you're taking maximum advantage of that, you can run more SFM than the manufacturer would normally tell you to.

OK, second thing these toolpaths do is take advantage of radial chip thinning. When you use a width of cut that is less than 1/2 the diameter of the cutter, a funny thing happens--the chips are thinner than the normal speeds and feeds equations tell you they should be. You can see why from another diagram:

You can use the G-Wizard Machinist's Calculator to compute feedrates adjusted for chip thinning, but the idea is to increase the feedrate so the chip thickness is restored to the recommended chipload.

Lastly, one of my G-Wizard Beta Testers sent me a wonderful video that shows just how crazy fast you can go with this stuff:

[nomedia="http://www.youtube.com/watch?v=OzPpe8dI06o"]YouTube- Demo in a box, wide open![/nomedia]

Very cool stuff.

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

04-28-2010, 03:27 AM #3

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 447

Bob,

Thanks for the extensive explanation. To continue the academic part of things and using my example of cutting off a long strip of metal from the top of a bar, it looks like it would still be advantageous to employ the new technique even though a pocket is not being created. Run up the ipm, reduce the radial depth of cut, and rapid back to take another cut while entering and leaving the material in circular or arch motion.

This can be done with CAM software by effectively creating a pocket for the tool paths to generate in while placing the work in only a portion of the pocket. When I get a few minutes I'll do a drawing with the tool paths visible.

Vern

-

04-28-2010, 10:33 PM #4

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 447

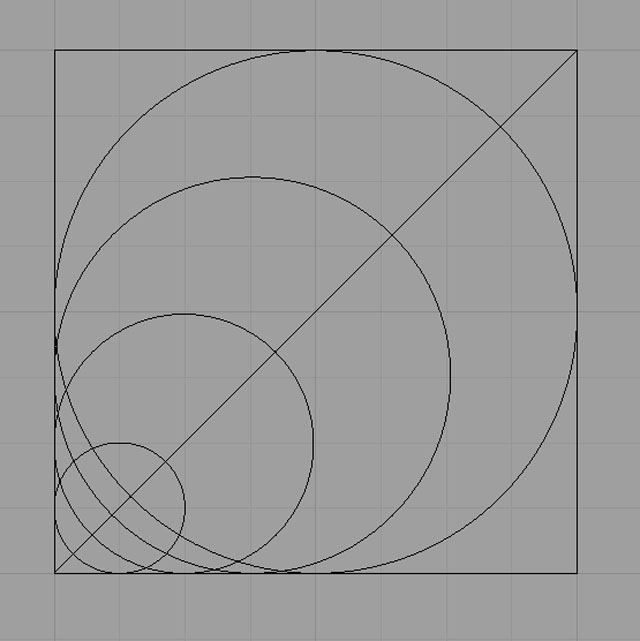

Had a couple of minutes to make a simple picture. As previously described, the idea is to trim down the height of a long bar. For argument sake lets say we are using a 1/2" end mill and the bar is 1" wide and 3" long. I have shown the tool paths the CAM software creates employing the "Trochoidal Milling" technique. So -- while this method is generally employed to cut pockets or slots I would think it's advantages would be just as applicable to this type operation. I have noticed that this type of machining is not very efficient unless you can take a significant depth of cut. The reason is all the time the tool spends out of the material.

The green lines are the tool path of the cut and the blue lines are the rapid back to the next cut. All lines represent the center line of the tool.

Similar Threads

-

Too Much Information!!!

By HLF Ordnance in forum Benchtop MachinesReplies: 6Last Post: 11-02-2009, 08:06 PM -

OKK INFORMATION

By GERARDO in forum OKKReplies: 1Last Post: 06-27-2009, 12:10 AM -

Hello All - looking for information on this:

By maglinvinn in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 01-11-2009, 06:53 PM -

CNC Information

By bshaker1 in forum Waterjet General TopicsReplies: 24Last Post: 12-31-2007, 10:06 AM -

Please a need an information

By giansa in forum Uncategorised CAM DiscussionReplies: 5Last Post: 11-26-2003, 11:24 AM

Reply With Quote

Reply With Quote