help me making program by mastercam v9

line part:http://www.mediafire.com/?sharekey=3...095ac91101628c

Results 1 to 9 of 9

-

04-29-2010, 07:09 AM #1

rotary 4 axis making mill cnc program by mastercam

-

05-05-2010, 02:06 AM #2

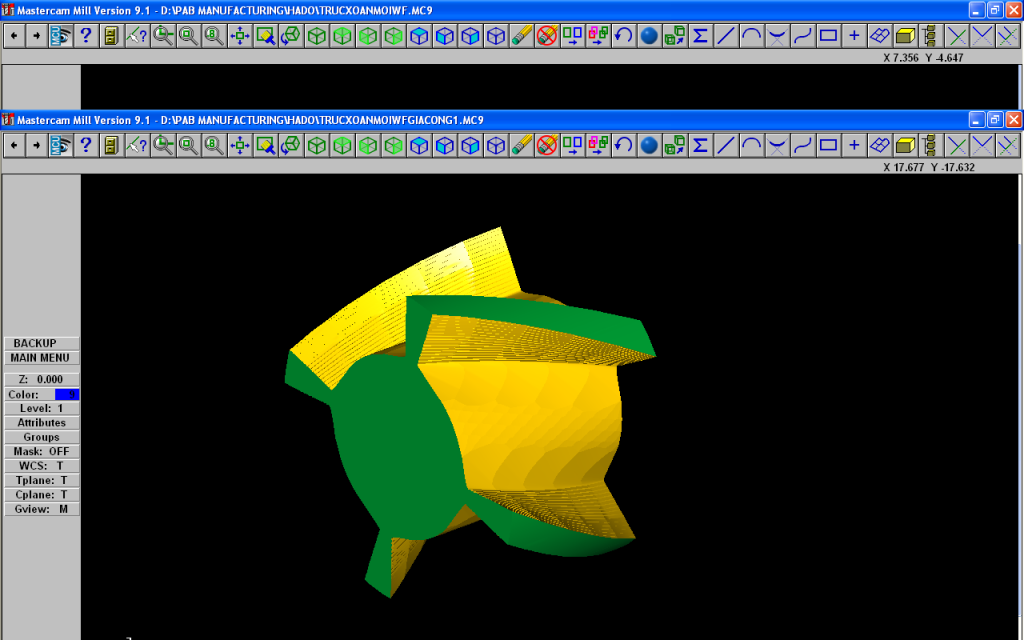

i have made program but rotary cut not match,see my post picture folow line:http://www.mediafire.com/imageview.p...r1y0l0&thumb=5

-

05-05-2010, 03:27 AM #3

Flies Fast

Flies Fast

- Join Date

- Dec 2008

- Posts

- 3109

Swarf 5ax would be best done using chains

1 operation each for front wall, and back wall

select bottom chain 1st to set tool offsets, top rail to set tool tilt or rotation

keep the chains simple and short when learning, long contours can have sync problems

Parameters

comps ON - "Computer"

entry/exit - both on and set the same, length=10, thickness = 2 , height =0, pivot = 0

depth cuts and multipasses work similar to contouring operations

Chord height affects the surface finish, big # = big facets, suggest 0.001mm or less for finishing

geometry

4 axis = ON

chains ( bottom contour 1st, then top)

surfaces = controls the tool depth on the cutter edge instead of through the centre line

-

05-06-2010, 08:27 AM #4

I also have made progaram swarf5axis but it is only for finish cut,i like to making program rotary simulator cut 4 axis,but not succefull,see line below:

http://www.mediafire.com/i/?mz4zzr1y0l0

-

05-06-2010, 01:22 PM #5

Flies Fast

Flies Fast

- Join Date

- Dec 2008

- Posts

- 3109

Are you saying that the picture does not look good ?

1- the verify looks very rough , big facets etc ?

or

2- the verify picture does not match the mastercam model ?

if #1, your verify settings are incorrect, try using "true solid" and high quality not speed, tools should be "as defined".

if #2, your comp settings are wrong, only use "Computer" for any 4 or 5 axis operation, using "Off", "Wear", "Reverse wear" and "Control" will not give correct code. Unless your machine is capable of adjusting comps in 4-5 axis, most will only do the 2 that make up the tool plane (is XY,XZ,YZ). The other just controls the depth.

The settings I suggested, I used on your session, and the verify shape ended up the same as the model.

Note--

swarfing--is best done with wireframe, not surfaces.

Depth control- let mastercam control that with a surface for the floor- your tool won't gouge the part. "Use bottom rail distance" is good for having the tool project past the lower contour, it will not control the leading or trailing quadrant points on the bottom of the cutter

-

05-07-2010, 05:26 AM #6

Thanks for your help me,swarf wireframe i have made is only for finish cutting,can you help me how to cut the cylinder shape.i have post immage after manifacturing for you check:http://www.mediafire.com/?cwnf3kgmiow

thanks!

-

05-12-2010, 08:02 AM #7

TODAY I HAVE POST THIS FILE OF MC9 AND ROUND MILL,BUT THE SHAPE IS NOT MATCH,CAN YOU CHECK AND HELP MANUFACTURING ON MASTERCAM,CAN YOU SEND FILE TO MY YAHOO: [email protected]

http://www.mediafire.com/?jmm2f3vzwzi

THANKS YOU SO MUCH!

-

05-28-2012, 06:18 AM #8

Member

Member

- Join Date

- Dec 2009

- Posts

- 166

Is this what you want

-

05-28-2012, 06:28 AM #9

Member

Member

- Join Date

- Dec 2009

- Posts

- 166

Is this what you want

Similar Threads

-

NEED THREAD MILL PROGRAM FOR C-AXIS

By BAD DOG in forum Daewoo/DoosanReplies: 10Last Post: 03-05-2015, 04:59 AM -

DIY Rotary Axis on Sherline Mill.

By mgjones in forum Benchtop MachinesReplies: 33Last Post: 02-23-2010, 06:27 PM -

(Mastercam) Program 4th axis contour around rectangular part

By imageman127 in forum MastercamReplies: 4Last Post: 01-13-2010, 05:41 PM -

RFQ - Program Emco 7 Axis Mill/Turn

By C5Frenzy in forum Employment OpportunityReplies: 1Last Post: 09-19-2009, 04:48 PM -

Help in making a 5 axis mill

By alexis159 in forum DIY CNC Router Table MachinesReplies: 10Last Post: 09-24-2008, 02:36 PM

Reply With Quote

Reply With Quote