Thread: XZero CNC

Results 2,821 to 2,840 of 4515

-

10-21-2012, 02:34 PM #2821

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

XZero cnc

-

10-21-2012, 02:40 PM #2822

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

-

10-21-2012, 02:47 PM #2823

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

Just a straight edge of any kind would work. The mount will fit almost to where it needs to be. if you put on plate, just let it sit freely on the bolts and just check to see if both side have the same amount of space on each side, tighten it i bet it is where you want it to be without any gauge

XZero cnc

-

10-21-2012, 02:53 PM #2824

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

If you turn plate upside down from how you have it. it will come over and cover for ballnut on top. On the way you have it mounted, the spindle will sits an inch lower on the mount. other way an inch higher. The design is to give lots of ways to get the spindle to where you want it.Alignment would be from Z axis to table top, not top of bearing house

XZero cnc

-

10-21-2012, 02:55 PM #2825

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 178

I would really like a reply about prox wiring.

-

10-21-2012, 02:56 PM #2826

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

-

10-21-2012, 03:10 PM #2827

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

-

10-21-2012, 03:13 PM #2828

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 86

I just wanted to add a note for those reading this forum.

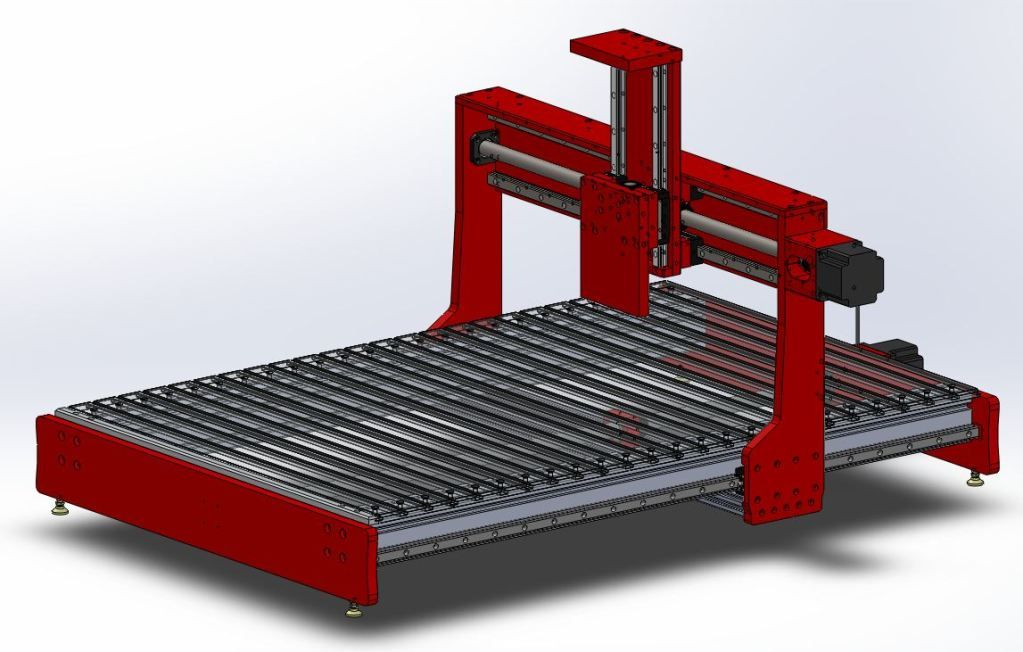

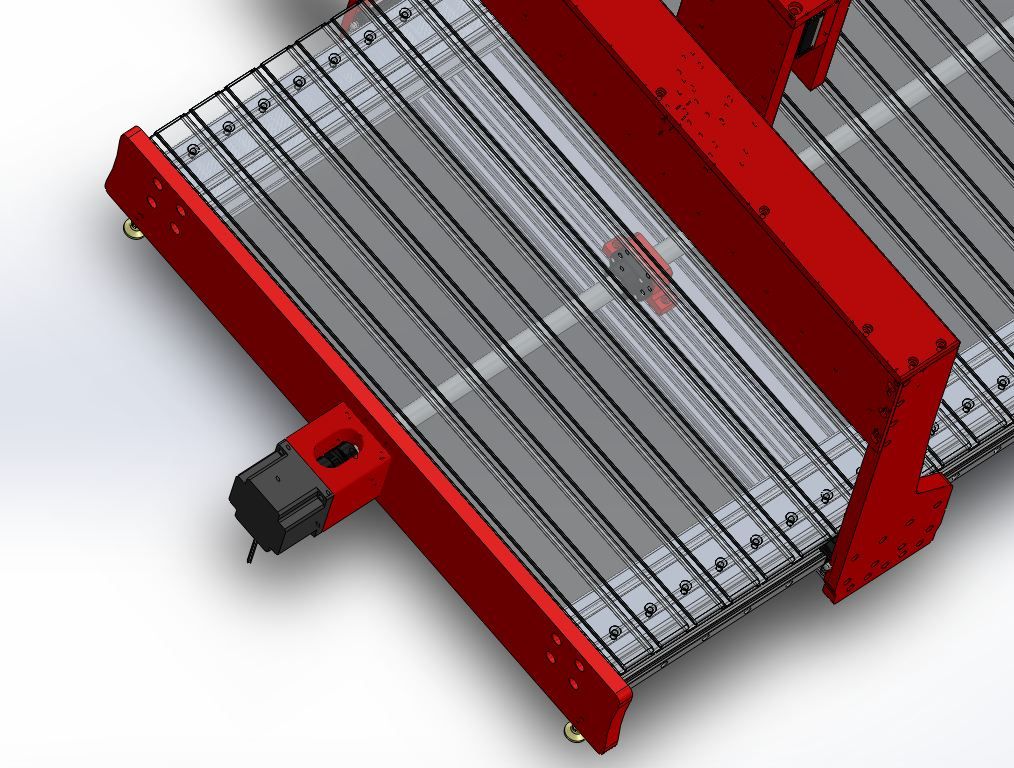

I have researched and seen many different CNC machines on the market, XZero cnc seems to be extremely well constructed and value for your money. There were a bunch of changes I wanted so I decided to design a machine for myself completely based on the RAPTOR design. It would use more precision linear motion, ect.

I can tell you that for the amount of time and money invested, EVERYONE should just buy it from George. It has been very fun but I have a ton of more work to do and it would just be a lot easier to buy from George! TRUST ME!

Rob

-

10-21-2012, 03:16 PM #2829

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 178

-

10-21-2012, 03:34 PM #2830

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

Hi Robert , yes Thanks, As i told you , if you have a machinist that will make one off on all the aluminum parts for cheaper than i sell complete machine for i would be surprised.I know what one off stuff cost to get made.

I would not say better linear . i also have SBC rails which all come with preload. Same as IPEC got pricing for you and they will have Thomson rails also soon . Would you get anything from using THK ballscrew compared to TBI on this style router , very slim if anything other that wallet a lot skinnier.

I would change your motor mount design.

BUT you made one BIG mistake on your drawing, you forgot the XZ on the uprght lolXZero cnc

-

10-21-2012, 03:59 PM #2831

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 86

George,

Your 100% right which is why I changed it to this

You know i made some mistakes buying some ballscrew end supports from Ebay which were too big and really terrible when it came to quality. Other than that i have only purchased motors and controls nothing else mechanical. Designing this have been fun but nothing says I can't still just go buy one from you.

I read the last few pages back where you mentioned the phantom and predator. When will those be released and be available? Like I said, i should probably just buy a machine from you if you can accommodate a few items.

Cheers

Rob

-

10-21-2012, 04:14 PM #2832

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 178

That remind me of my mistake...!

Not taking it red anodized

Envoyé depuis mon GT-P7510 avec Tapatalk

-

10-21-2012, 04:20 PM #2833

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 86

-

10-21-2012, 04:27 PM #2834

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 178

-

10-21-2012, 06:02 PM #2835

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

The Aluminum for anodizing you will have to take orbital sander to it. You have to remove all extruded lines on it or it will show up more. If you prep yourself it saves a lot of money, The more you sand the shinier it will be . IF you bring to anodizing shop and they do that color you want all the time, they will give better deal than if it is custom color . In Quebec there must be tons of them.

Here it is $200 for 3 pieces or 50 pieces. Minimum chargesXZero cnc

-

10-21-2012, 06:19 PM #2836

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

Ballscrews from Ebay, by the time you add all up with shipping and everything it would be more then buying good ones here . Only problem is getting them turned , which is a lot of money here to get them right .

I will have kits for people own machines that will be machined here and true once shipment get here by sea.

i have not got one good ballscrew from china. 5 out of 10 can be used on a machine.

Same as TBI blocks, no matter how many time you complain about the way they are shipped, it never changes. Blocks come without all bearing, busted retainers from shipping all lose in box. last shipment 8 blocks busted out of 24.

Now i will only use SBC or Thomson. By time you add up losses it cheaper to pay more here.

I get ballscrews turned in Taiwan and now they also not turned turn. Or to short or to long all from the same drawing.

The Demon wont be done till backing plate extrusion is done, it will also be turnkey only

The Predator start around $4500 for 40x48XZero cnc

-

10-21-2012, 06:22 PM #2837

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

But if you wanted to make the rest of the machine, i still have 1 inch uprights and 1 inch backing plate at 40 inch wide. For 20mm rails

XZero cnc

-

10-21-2012, 06:38 PM #2838

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 174

-

10-21-2012, 06:43 PM #2839

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 174

Without resistor......coming soon the video

.

-

10-21-2012, 06:52 PM #2840

Company Representative

Company Representative

- Join Date

- May 2008

- Posts

- 4068

The problem with painting, if any of the mounting areas get paint , nothing would fit.

The Raptor machines that would cause all kinds of problemsXZero cnc

Similar Threads

-

XZero CNC

By gio666 in forum News AnnouncementsReplies: 3Last Post: 04-30-2013, 05:53 AM