Hi.

Is it possible to flatten a 1 1/4" 6061T6 aluminum tube at one end, lets say I need a flat end centered about 1" to 2" long. Should annealing take place or its possible to cold work it?

How about 6063T5? I have this one locally.

How about buying 6061T0 and cold working it and then hardening it, maybe in some other shop, since I don't have a kiln. Is 6061T0 being sold?

My question may sound naive, I don't know much about aluminum, I have this idea of a structure I would make out of aluminum tubing.

Thanks for your input.

Thread: Flattening aluminum tube?

Results 1 to 11 of 11

-

09-02-2010, 08:23 PM #1

Registered

Registered

- Join Date

- Feb 2004

- Posts

- 466

Flattening aluminum tube?

-

09-02-2010, 08:55 PM #2

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Back years ago in the Airforce, I was in a skin bay overhauling A4K Skyhawk flight controls. We started getting delaminated rudders in, and tried to make flat sided oval Alloy tube out of round.

We tried annealed tube, filled with sand, and then pressed, but never got a good flat. There are some low melting point alloys which might work through.

You won't be able to cold work T6 much without it cracking. Do you have a drawing of the peice? Making things with flattened ends of tubes is seldom structurally efficient.Regards,

Mark

-

09-02-2010, 09:30 PM #3

Registered

Registered

- Join Date

- Feb 2004

- Posts

- 466

Thanks for the input Mark.

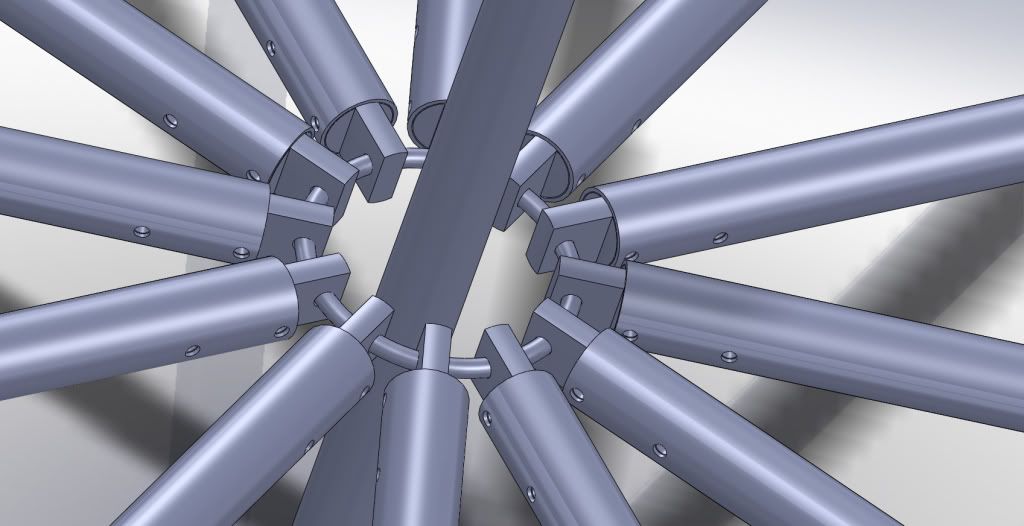

This is an assembly of what I am trying to do, basically it is an umbrella mechanism, it is in the early stages and I am thinking of modeling a sheet metal hub that will hold to the ring and allow the assembly to slide up and down the mast.

While I was modeling it I was thinking "wouldn't it be easier to simply flatten the tubes instead of machining this joiner piece you see inside the tubes.

I am trying to get a cost effective solution to this as I do not have a milling machine, working 6061 T0 would be ideal and then hardening it, at least that is my fantasy.

-

09-03-2010, 10:02 PM #4

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

How do you mount the flattened tubes onto the ring?

If the stresses a low, then flattening the end would probably work, but you would have to do it in 0 or W state, and then when you heat treat teh tubes back up to T6, they will likely warp all over the place (unless they are quite large diameter).

How many cycles will be required? The holes in the flattened alloy tubes may slog out pretty fast.

Try it.Regards,

Mark

-

09-03-2010, 10:48 PM #5

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 127

Would everything still fit if you epoxied plugs into the ends of the tubes and then drilled through the whole thing? As RotarySMP says, it seems like holes drilled through the walls of a tube might wear and warp really quickly.

You could make the end pieces with a bandsaw pretty quickly.

-

09-04-2010, 12:48 AM #6

Registered

Registered

- Join Date

- Feb 2004

- Posts

- 466

I believe Mark is referring to the holes in the flattened tube, they will wear out, I think he is right.

Pehaps I should explore easier ways to machine the plugs as you say Drassk. Would it be an option to secure the plugs inside the tubes using only structural adhesives?

Which adhesive could it be?

The ring I modeled as a whole, but in reality I think I would use a stock bar of metal and coil it, then cut out and solder once the plugs are inserted on. The sheet metal hub I mentioned would wrap around the exposed parts of the ring like fingers.

-

09-04-2010, 02:48 AM #7

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 0

Why use Allum ??? there has to be something lighter and more "moldable" to suit your application.

-

09-04-2010, 05:21 AM #8

Registered

Registered

- Join Date

- Feb 2004

- Posts

- 466

Hi Mike.

Like what for example?

The structure is intended is for a fold able recreational vehicle that will support 1 person. 6061T6 naturally comes to mind.

-

09-04-2010, 08:02 PM #9

I would make inserts and glue them in with loctite 638 retaining compound.

-

09-06-2010, 07:08 AM #10

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Virtually impossible to suggest something that approaches a "best practice" approach without knowing the volume needed.

More info please.

ThanksThe Manufacturing Reliquary

http://cmailco.wordpress.com/

-

09-07-2010, 07:36 PM #11

Registered

Registered

- Join Date

- Feb 2004

- Posts

- 466

I have continued this here http://www.cnczone.com/forums/showthread.php?t=111580

Similar Threads

-

Aluminum tube

By m-134b in forum Employment OpportunityReplies: 25Last Post: 12-28-2009, 04:01 PM -

Best Way to Bend Aluminum Tube ???

By twocik in forum Uncategorised MetalWorking MachinesReplies: 18Last Post: 07-22-2009, 07:39 PM -

pressing aluminum into an aluminum tube

By Fishin_Rod in forum Mechanical Calculations/Engineering DesignReplies: 24Last Post: 07-01-2009, 06:23 AM -

aluminum table tube

By dgalaxy in forum DIY CNC Router Table MachinesReplies: 2Last Post: 05-09-2005, 01:23 PM -

Where to find Aluminum Tube

By NeoMoses in forum MetalWork DiscussionReplies: 3Last Post: 01-22-2005, 10:54 PM

Reply With Quote

Reply With Quote