You can make it out of anything fairly solid, I 3d printed mine but hardwood, plastic, aluminum etc. will do fine even cardboard tubing wrapped in tape.

Hoss

Thread: Hoss's G0704

Results 6,401 to 6,420 of 6871

-

02-12-2016, 12:50 AM #6401

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

02-17-2016, 12:59 AM #6402

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 17

Hoss,if you dont mind I have a couple questions regarding setting up a C6 board for Mach 3 spindle control.

I noticed that your wiring diagram has the C6 board's analog outputs connecting to the g0704s p2 and F-, but cncpc's diagram shows it connecting to the p1 and p2 terminals. Will both methods work? If so, is there any reason to use one over the other?

Also, in order to switch the spindle off/on in mach3 will I need to wire anything into the C6 boards relays, or will turning the spindle off in Mach3 kill the voltage from the C6's analog output and effectively shut off the spindle?

-

02-17-2016, 01:34 AM #6403

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

Don't know what diagram you looked at but the one I used is this which uses P2 and F-.

http://cnc4pc.com/Tech_Docs/KBIC.pdf

I didn't use the relays either, the C6 will take the rpm to zero if the pot is adjusted correctly, you should still cut power to the spindle when you are done machining.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

02-17-2016, 04:51 AM #6404

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 17

-

02-17-2016, 03:52 PM #6405

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

Though they appear similar make sure the board you have matches the layout of the diagram, the one I used matched mine but they may have changed over the years.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

02-18-2016, 03:35 AM #6406

Registered

Registered

- Join Date

- Jan 2016

- Posts

- 6

Re: Hoss's G0704

OK got my belt drive spindle going today and did some bearing break -in...... the question is what type of bearing temperatures are good operating temp ? after the break in the head was rather warm and non contact was reading 127.4 F thats on the cast iron next to the big bearing on top not the actual spindle bearing . those seem to run cooler at 108 as close to the bearing as I can get a reading . Are those good ? Bad ? mediocre ? the treadmill motors outer casing was at 122 Farenheit . I let it run for about 10 minutes at 4000 rpm and thats as hot as it got . I did utilize the fan that came attached to the treadmill motor. I was going to fab a protective case around that. Any input is good input. Thank you for listening to my ramblings I know you guys get tired of answering the same **** over and over .

-

02-18-2016, 03:43 AM #6407

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

Temps under 160F are considered ok so you are fine.

They should get cooler as time goes by as they break in more.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

02-27-2016, 06:50 PM #6408

Registered

Registered

- Join Date

- Oct 2013

- Posts

- 17

Re: Hoss's G0704

Hi There,

I'm converting a G0704 right now using Dave from Arizona videos ball screw and cnc conversion. Is extending the Y-axis just a matter of doing some clearance machining to the base of the mill?

-

02-27-2016, 07:38 PM #6409

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

Why don't you email him about it, this thread is not about his conversion.

My extended travels for the Y require a longer Y ballscrew and a different Y mount.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

03-01-2016, 07:41 AM #6410

Registered

Registered

- Join Date

- Oct 2013

- Posts

- 17

Re: Hoss's G0704

My apologies hoss....wasnt trying to step on anyones toes. I was planning to purchase your dvd series i was just curious if your methods would work with my current stuff. I purchased that kit because i don't have the ability to make my own mounts.

Again sorry, I'll email the guy i got it from.

Jason

-

03-01-2016, 02:40 PM #6411

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

No worries, dave would be the best to answer questions about his kit.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

03-03-2016, 05:33 AM #6412

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 114

Re: Hoss's G0704

Hey Hoss,

When you built your chip tray and added the doors and walls, can you tell me what part # you used for the Aluminum extrusions?

Aluminum Extrusions of MISUMI?MISUMI USA

Thanks!

-

03-03-2016, 01:35 PM #6413

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

These are what I used. KHSF3

Aluminum Extrusion - 3 Series, Base 15, Configurable Length?MISUMI?MISUMI USA

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

03-06-2016, 08:10 AM #6414

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 114

Re: Hoss's G0704

Thanks Hoss!

-

03-08-2016, 06:05 PM #6415

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 17

Re: Hoss's G0704

I appreciate the responses here and all the information posted by Hoss and others, without it I doubt my G0704 conversion would have been possible.

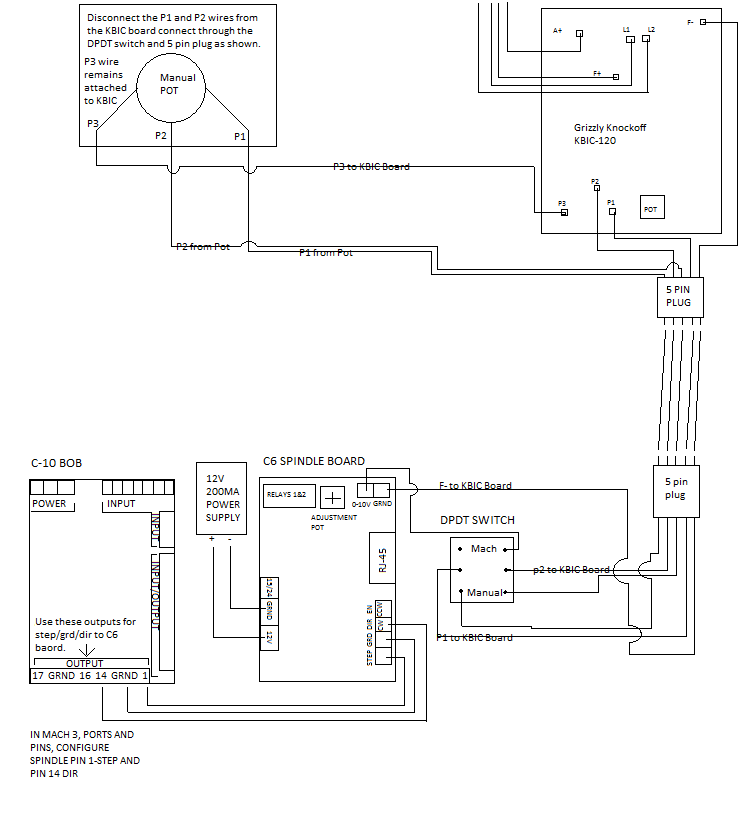

I got my C6 spindle wired up and it works great. I cant get the indicated RPM in Mach3 to match the actual spindle RPM, but I can get pretty close. I wired mine using a DPDT switch, to allow switching between manual and Mach3 control. So far I have about 10 hours on it, and so far so good. When Mach3 runs my G-code program, the spindle kicks on, goes to an approximation of the correct RPM, then the program runs. When it finishes the spindle turns off automatically.

Since the information here was so valuable in building my G0704 CNC, I made a wiring diagram showing how I wired my CNC4PC C6 board up to my C10 breakout board through a DPDT switch. Here's the diagram, feel free to copy it, use it or post it anywhere else you like.

-

03-08-2016, 06:19 PM #6416

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Hoss's G0704

Nice job, much more detailed than what I posted for my switch to change between Mach and manual control.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

03-12-2016, 08:20 PM #6417

Registered

Registered

- Join Date

- Aug 2003

- Posts

- 329

Re: Hoss's G0704

I have been looking at a replacement motor for the G0704. I emailed Weiss and haven't gotten any response in two weeks . I started looking around at 3 phase motors and belt drives and found this one and I wondered if anyone has any thoughts?

https://www.zoro.com/leeson-metric-m...1265/?q=LEESON

Metric Motor, 3-Phase, Totally Enclosed Fan-Cooled Motor Enclosure Design, 1-1/2 HP, 1.10 kW, Nameplate RPM 3475, Frame D80, Voltage 230/460, 60/50 Hz, 3 Phase, Full Load Amps 4.2/2.1, Rigid Base Motor Mounting Type, Motor Thermal Protection None, Insulation Class F, Service Factor 1.15, Ball Bearings, Frame Material Aluminum, Max. Ambient Temp. 40 Degrees C, CW/CCW Motor Shaft Rotation, Nominal Efficiency 84.0 Percent, Continuous Duty, 3001-3600, UL Recognized, CSA Certified, CE CertifiedJoescnc 4x4 R&P Router, Minimill, Minilathe, CNC Foamcutter, laser cutter, Vectric Aspire. http://makermasters.com, http://themakersguide.com

-

03-13-2016, 01:22 AM #6418

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 114

Re: Hoss's G0704

Bgriggs,

I sent Weiss an email with part #/Sn from Hoss and I was able to get a new motor via paypal from them in <5 business days. (3 actually). West coast.

-

03-13-2016, 03:16 AM #6419

Registered

Registered

- Join Date

- Aug 2003

- Posts

- 329

-

03-13-2016, 04:01 AM #6420

Registered

Registered

- Join Date

- Aug 2003

- Posts

- 329

Re: Hoss's G0704

I just cleared my inbox.

Signal9.Joescnc 4x4 R&P Router, Minimill, Minilathe, CNC Foamcutter, laser cutter, Vectric Aspire. http://makermasters.com, http://themakersguide.com

Similar Threads

-

Hoss's G0704

By hoss2006 in forum Benchtop MachinesReplies: 944Last Post: 03-25-2016, 12:48 AM -

Another G0704 conversion - Hoss's plans - LinuxCNC control

By otto_pjm in forum Benchtop MachinesReplies: 9Last Post: 11-14-2013, 06:26 PM -

G0704 Y axis Thrust Bearing Block and Stepper mount from Hoss Plans

By LLDesigns in forum RFQ (Request for Quote)Replies: 1Last Post: 12-12-2012, 02:49 AM -

RFQ A few parts from Hoss G0704 Plans

By LLDesigns in forum RFQ (Request for Quote)Replies: 3Last Post: 10-21-2011, 09:13 PM -

Hoss does it again!

By tooManyHobbies in forum Benchtop MachinesReplies: 3Last Post: 11-01-2008, 06:29 AM

Reply With Quote

Reply With Quote