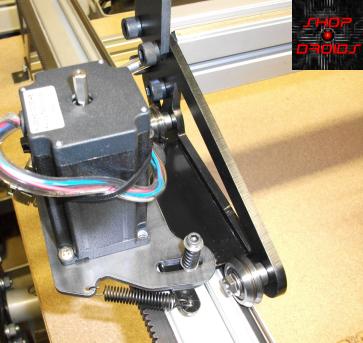

I've been on this board a while so decided to share some pictures of my small cnc plasma cutting machine. I don't have much room in my shop so this little machine has been a blessing as it has fulfilled my current needs. It was originally a portable unit but I have recently upgraded to adding legs and enclosing the table frame. The plasma cutting slat supports were added to the inside portion of the table frame assembly. This will allow to "bow" the support rails when placing them inside to keep them rigid. I should be able to now switch easily between a router for wood work and plasma for steel cutting just by adding/removing a tabletop. This machine has a cutting area of 29" x 29". Rack & pinion on all 3 axis utilizing dual motors on the gantry. Six inches of Z axis travel with built in "float" for "touch and go" cutting. Electronics is the G540 controlled by Mach3, Hypertherm PowerMax 45 Plasma Cutter.

Recently purchased the LCTHC from CandCNC. Hoping to get it installed soon when I get some free time... In the process of making the water tray for this machine as well. I'll have more pics soon...

Thread: My PlasmaBot

Results 1 to 20 of 48

-

11-14-2010, 07:57 PM #1

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

My PlasmaBot

-

11-15-2010, 02:54 AM #2

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

Tulsa Turbo, where are you located? Are you a muffler shop? I saw the bender. I live south of Bixby. Im gathering parts for my table now I have the 4 axis blade runner package from CandCNC, and some of my gantry parts............john brown [email protected]

-

11-15-2010, 03:18 AM #3

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

Hi John. Nah, I don't own a muffler shop just my own garage/hobby shop. I enjoy passing the time, when I have time that is, working on old toyotas and mazda rotaries.

I'm located in Broken Arrow. If you want to meetup sometime and discuss cnc stuff, just shoot me a pm.

-

12-06-2010, 06:02 AM #4

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

Finally got around to installing a water tray. This will definitely cut down on the dust and mess this winter...

-

12-07-2010, 06:56 AM #5

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

Table is looking good, I'd like to come look at it some evening.........jb

-

12-27-2010, 02:44 PM #6

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

I'm on vacation this week if you want to drop by. Just give me a ring or drop a private message here as I get terrible cell phone reception when I'm in the shop. I would like to check out your new build as well...

I did get to put in the treated water mix into the tray. It took 17 gallons. Afterwards I had to cut out a couple of parts from 1/4" steel which worked out perfect to test out the tray. All I can say is "Why did I wait so long to make the water tray"...

No more having to roll the machine outside to cut! I'm currently putting together the "Low Cost Torch Height Control System". Hopefully I can it all wired up while I'm on vacation. The last couple of days was chalked up as a loss "not able to play in the shop" recovering from a major computer crash but all is good now.

My Blog

My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

12-28-2010, 05:20 AM #7

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

I decided I wanted another controller which will be used strictly for the plasma machine so I gave myself a christmas present (a new G540 and power supply)

I had been sharing my original G540 controller between three cnc machines. It only made sense for me to go that route with the addition of a torch height control system that I'm currently wiring up.

I had been sharing my original G540 controller between three cnc machines. It only made sense for me to go that route with the addition of a torch height control system that I'm currently wiring up.

So with that said, I decided that a new control box was in order. I wanted something cheap, simple and portable. This is what I came up with so far ($20 harbor freight metal tool box). I took the tool tray and cut off the handle portion and set it upside down in the box. Worked out better than I expected.

I should have the basic wiring finished up by tomorrow so I can test it. I'm still waiting on the emergency stop switch to arrive in the mail...My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

12-28-2010, 06:03 AM #8

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

I'm going to be out of town tuesday, but I will PM you as soon as I can. I had the idea to build a smaller lighter weight machine first, then go with a larger one if I needed to. The overgroovin' instinct kicked in and I'm still buying parts instead of cutting metal. I am very intrested in your machine.........jb

-

01-06-2011, 10:38 PM #9

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

I've been wanting a plate marker so I decided to finally fab one up. To do it the way I wanted required changing the Z axis plate a little by adding mounts for the plate marker attachment. The plate marker will consist of mainly a sliding support plate (for adjustments) onto which a small linear rail and air actuator will mount on. I still have to fabricate the plate for the marker that will mount onto the linear rail block. I will post more picture as I progress further on this little project.

Here is what I have so far:My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

01-07-2011, 06:09 PM #10

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

Hi John. let me know when you get that going. I'd like to see it in action. as soon as the rest of the parts get here I'm ready to start on my table...........jb

-

01-17-2011, 02:37 AM #11

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

shot you a pm!.... Would you be so kind as to show how your X-axis bearing rides, and how your motors mount?.... Those brackets, are they steel or aluminum?... Thanks a bunch!

-

01-17-2011, 01:23 PM #12

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

The plasmabot is a early prototype. I have since upgraded the drive rack from 1/4" to 1/2" as shown in the image. You can see the upgraded version which I use with a router here:

http://www.cnczone.com/forums/862803-post1.html

The v-grooved wheels ride on a precision machined aluminum anodized rail with hardened embedded steel races as shown in the image.

All brackets and support rails are steel.Those brackets, are they steel or aluminum?... Thanks a bunch!My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

01-18-2011, 12:12 AM #13

Registered

Registered

- Join Date

- May 2010

- Posts

- 63

Where do I get that profile , is that 80/20 ? I want some of that material with the vee rails built in . How much does it run ?Thanks !

-

01-18-2011, 01:03 AM #14

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

He sells the whole kit...... NoSleep Studio

-

01-18-2011, 07:25 PM #15

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

I am looking to start adding the pneumatic lines to my plate marker. Does anyone have leads or links of where to go to purchase the lines and fittings similiar the ones shown in the photo attachment? TIA!

My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

01-18-2011, 10:12 PM #16

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Here you go!.... Thanks for all the help!

push in fitting items - Get great deals on Business Industrial, eBay Motors items on eBay.com!

Or if you want a legit source!.... Or just search "push in fitting" on yahoo, you will get the phonebook!....

Push In Fitting, Air Fittings - STC Fittings

I love these things!... they are so easy to use, we get them in kits sometimes at work... but the links above is much cheaper!!! $1.00 - $2.50 each!

-

01-18-2011, 10:22 PM #17

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

When you start looking for tubing... You are looking for PU tubing... or polyurethane tubing.... Here is a fast and dirty link to some.... PU 95A Polyurethane Tubing 1/4" OD CLEAR 30m (98ft) - eBay (item 260441346843 end time Jan-26-11 05:14:02 PST) No i dont know them.... Just check your thread size you need... with the PU size you need... then order the tube for that connector... there are Metric and SAE sizes, just to confuse the matter more!.... lol... check the link, he has much more in stock and sizes too.... Have a good one, KW

-

01-20-2011, 01:03 AM #18

Registered

Registered

- Join Date

- May 2010

- Posts

- 63

That aluminum profile is pbclinear.com the style is # ivtaag .In case anyone wants to know where to get it .

-

01-23-2011, 08:34 PM #19

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

Just in case someone may be interested, I have been working on another style plasma machine utilizing a different carriage for supporting the gantry on another style rail. I have an extra set of plates that I will be listing on ebay tonight for those preparing to do a new build and would like to utilize this style of motion for their machine.

Here is the item number to the auction when it comes up tonight around 8pm central time: 160536401731

My Blog

My Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

01-25-2011, 06:50 AM #20

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

Hi John. Is this a different style than the machine I saw at your shop? You do nice work.......jb

Reply With Quote

Reply With Quote