Hey everyone, long time lurker, first time poster.

I am looking for a CNC milling machine. I have been scouring kijiji and craigslist for cheap ones that I can convert, but haven't had much luck. There are lots of bridgeports for sale, but they are definitely too large for my purposes.

I currently have a Unimat lathe/mill and a sherline lathe. I lucked out and bought both on the cheap. I am going to get rid of the unimat as the milling capacity isn't sufficient. My location is Toronto, Canada.

I want to use the CNC to make molds and complex parts for engineering side projects. I would also like to route and drill PCB boards. I am looking for a dual purpose machine, with the emphasis on CNC machining before routing capabilities. I will use the toner transfer - etch pcb method and then drill through holes with the CNC if routing is not feasible.

I have been strongly looking at purchasing a CNC ready package from Sherline, but would like to know what else is out there. I talked with one of the salepeople and she mentioned about 3300 dollars for a computer ready CNC machine. That comes to about 4000 after taxes and shipping.

I have also been looking at this Atlas: King Industrial PDM-30/KCL52 Mill/Drill Machine with 1-1/4" Drilling Capacity and then sourcing upgrade kits. It seems the gecko servo kit goes for 900$, but I am unsure about the price for ballscrews, motor mounts, and antibacklash.

This would cost probably 3400 for everything, but isn't as simple to put together because of newbie risk (buying wrong stuff syndrome).

Because I am in Canada, it makes more sense for me to make a single purchase, rather than spread out my purchases (due to the ~50-150 dollar customs agent fee). For every additional supplier I buy from the costs go up by about 100 dollars for the additional customs agent.

I also want a 4th axis to work with at some point in the future. Depending on how expensive everything looks, I would just purchase the 4th axis with my initial purchase.

Can anyone give comments or help with regards to selection? I would put my upper price limit at CAD$6000 for a near turnkey solution.

Thread: Buying CNC milling machine

Results 1 to 7 of 7

-

11-19-2010, 02:27 AM #1

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

Buying CNC milling machine

-

11-23-2010, 06:59 PM #2

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 278

You should convert a bridgeport. I ha ve and would never do anything smaller again.

Bridgeport conversion parts are numerous and readily available.

It seems like its too big for a garage, but its not.

Go Bridgeport and you never regret having done it.

I converted with ballscrews, gecko 203V's, 870oz in steppers (pac sci) and a smooth stepper, and I have been REALLY happy with the results. 80IPM rapids, no step losses, power to spare and good positioning accuracy.

PM me if you want a parts list, with sources!

Best,

Nate.Nate.

Ann Arbor Meechigan

-

11-23-2010, 07:44 PM #3

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

Yes, please send or post here, there are numerous bridgeports for sale on kijiji, this may be feasible.

-

11-29-2010, 07:23 PM #4

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

What is the "jump on it" price for a bridgeport mill that functions? I see a few within driving distance and am wondering if I should jump on one. I would do the CNC conversion myself. Bridgeport seems to have the most readily available conversion parts.

-

11-29-2010, 07:37 PM #5

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

You need Servo Motor or Stepping Drive

You need Servo Motor or Stepping Drive

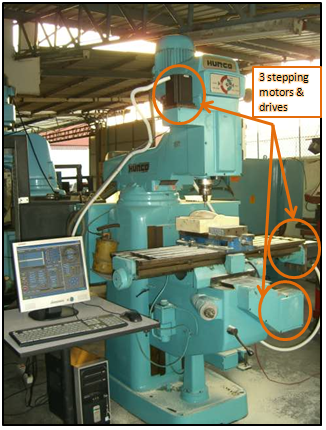

CHeck this out converted Hurco. It should be similar to convert Bridgeport:

SALE CNC Router Milling, CNC Laser, CNC plasma machine, China, Servo Motor Drive, UK, USA, Italy, Spain, Thailand

You can aslo see video:

[nomedia="http://www.youtube.com/watch?v=4fKc20rDyHQ"]YouTube - HURCO CNC Milling machine retrofit SaleCNC.com[/nomedia]

Must see the video it's cool good luck guys. I am happy with my CNC router, don't have to do anywork. I just make parts and make money hhehe

good luck guys. I am happy with my CNC router, don't have to do anywork. I just make parts and make money hhehe

-

12-02-2010, 07:01 AM #6

Dear Engeng,

I am happy to meet with you on CNCZONE .I am Mandy from China , our company is Jinan JCUT cnc equipment Co.,Ltd .

Dear ,from your description on cnczone , now you are looking for a miller machine that can do PCB and other material , right ? if yes , dear , our PCB machine can meet your demand easily , it is can process PCB material also some other material such as metal ,wood , plastic etc.

Dear , below is the information of our JCUT-3030PCB machine for your reference.

Standard Feature:

Model: JCUT-3030

Machined surface: single/double

Worktable board (mm): 300X300

Working speed: 8000mm/min or 4200mm/min

Means of communication: PCI or RS232

Working accuracy: 4-8mil

Least line diameter and least line spacing: 4-8mil

Operation system : WIN2000/XP/VISTA

Repeat Accuracy : 0.025mm

The least error of Data control drill : less than 1mil(0.015mm)

Function Request: Protel PCB document can be directly put in.(gerber)

Spindle speed: 24000rpm

Spindle power: 800W

Power supply: AC210-240V

Volume: 700X750X800mm

Net weight: 75kg

Gross weight: 90KG

Applications:

This machine is professional PCB machine , and also can be used for advertisement engraving, advertisement cutting, stone processing, Cu and AL molding, mold manufacturing, wood processing, craft manufacturing, light box cutting, building mold cutting, indoor decoration cutting, light equipment mold processing, sign and mark manufacturing, acrylic board processing, as well as stamp cutting etc

Dear, And if this one smaller for you , you can choose JCUT-4040PCB machine ,JCUT-4060PCB cnc machine or JCUT-5060PCB cnc machine . JCUT-6090PCB cnc machine etc hehe .

Dear, the JCUT-3030PCB machine now we just sell at 2799USD , you also can check the link of this machine in our ebay too , the link is 3030 pcb router pcb drill mini routing drilling machine - eBay (item 130449195096 end time Dec-27-10 22:46:46 PST)

Ok dear, if you need more information of this machine , please tell me your private email address ,then i will send more information including pictures sample pictures etc to your email address .

Looking forward to your early reply.

My msn: [email protected] and [email protected]

skype: wdzhangying

Regards

Mandy

-

01-04-2011, 08:51 PM #7

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 278

The jump on it price for a series 1 BP with 2hp motor variable speed head in fully functional condition is 1000.00 I bought mine on ebay for 250.00 It was only listed for a few minutes before I bought it.

ebay has some crazy priced BP's. some junkers for low money also.

I think that used machine tool dealers are always 33-500% overpriced on their used machines. I have yet to see a single machine at a used macheniey dealer that was not at least 33% over what it should have been. I suspect that they buy them very cheap from people who inherate them/ factory closedowns, clean them and then mark them at ridiculously high prices and wait for a sucker.

If you can get a 1980+ series 1 in good shape (ways and bearings) for under 1500.00 you are doing quite well. Thats without tooling. With tooling, its a whole different matter.

I personally will not buy from asia anymore. Quality is still quite poor and older american iron is plentyfull and affordable.

That said, half the parts on my 1982 series 1 are from asia, but built to bridgeports standards/fit and finish.Nate.

Ann Arbor Meechigan

Similar Threads

-

buying a spindle for a homemade cnc milling machine

By science_geek in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 05-05-2009, 11:48 PM -

thinking of buying pinnacle VQ 147 milling

By shay z in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 07-10-2008, 10:42 AM -

What to look for when buying a milling machine.

By Apples in forum Uncategorised MetalWorking MachinesReplies: 7Last Post: 03-03-2008, 04:19 AM -

What to look for when buying an old milling machine, with the view to CNC it?

By Apples in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 02-18-2008, 10:36 PM -

Use Machine Shop vs. Buying Machine

By imp22b in forum MetalWork DiscussionReplies: 15Last Post: 06-06-2007, 12:33 PM

Reply With Quote

Reply With Quote