Hello all!

I am currently in the process of designing my CNC machine to be desktop compatible(if that makes sense).

I'll try to update this with a few pictures/screenshots every day so i can get some good feedback for free!

So the build is going to be a fixed gantry with a moving bed. I decied to go this way because of 2 reasons:

1) when building a DIY machine and for the first time - less moving parts

2) since i want to cut aluminium and rack-pinion is too expensive currently its simpler to make a moving bed(just X axis).

Personally i have 2 questions to the wider audience:

1) can belt systems be used successfully to cut aluminium(and not some commie aluminium. proper 6082 T6 aluminium)?

2) is 10mm aluminium plates as the main construction material overkill or just about right?

Thanks!

Results 1 to 12 of 12

-

01-06-2011, 10:34 AM #1

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Fixed gantry build-newbie tuesday

-

01-06-2011, 12:51 PM #2

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 77

-

01-06-2011, 12:58 PM #3

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Boom - The idea is to ask if belts would work or not. i just find the belt systems to be slightly better. When it comes to moving bed vs gantry, i've seen moving gantrys with pinion and ballscrews - pinion is much more precise and reliable(i've seen big machines though, 3m+). ACME or ballscrews are the next logical choice after belts.

Drawings(or rather screenshots, no drawings yet) coming in 3-4 hours.

-

01-06-2011, 01:29 PM #4

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 77

I will not use belts for cutting alli. If you are talking about hobby grade components, I will definitely use ballscrew, or rack if it's a very long span.

"or ballscrews are the next logical choice after belts."

I would say it's the other way around. After adding gearboxes and what not on the belt system you will not save much if anything.

What size metal do you need to cut?

-

01-12-2011, 01:28 PM #5

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Hey everybody.

I got infected with a nasty virus, had some green stuff coming out etc.

Anyways - I had some time to think about things and this is what i came up with:

Acme threads

Linear rails and open pillow blocks

Aluminium plates from alu 8082 T6

The next thing i need to deduce is what kind of motor to use. I've leaned towards a nema23 with 1.8 NM of hold torque.

Spindle will be custom built and not a problem.

I promise some pictures by the end of the day . And thanks boomslang - good points.

. And thanks boomslang - good points.

T

-

01-16-2011, 04:47 PM #6

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Hello all.

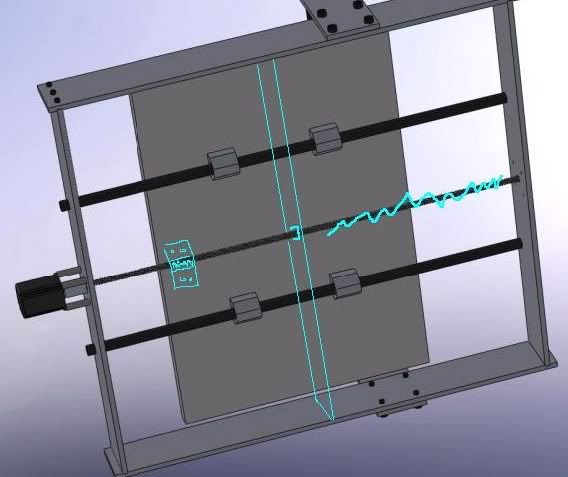

I now had some time to add elements and looking for some feedbacks.

Namely: how should i take care of the z-axis?

Feed back would be appreciated on all things

-

01-16-2011, 05:12 PM #7

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 77

What are the dimensions of the machine and rails?

I would put the bearing blocks on the bed as far apart on each rail as possible, it will help with binding and racking. Without dimensions (as I've asked ) it's hard to help.

) it's hard to help.

On Z, I will put the bearing blocks on Y and the rails on the moving part of the Z axis (hope that makes sense). That way the bearing support stays close to the work surface.

-

01-16-2011, 05:58 PM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

The unsupported shaft will flex too much to cut aluminum. Most find that they flex too much to cut wood.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

01-16-2011, 07:47 PM #9

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Hey guys.

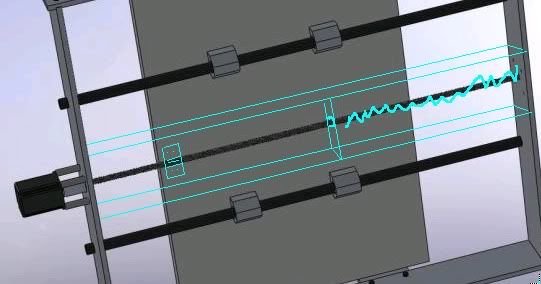

Dimensions are added as a picture.

The rails i selected were 20mm. If i switch it up to supported rails, would that deliver a more satisfactory result?

-

01-16-2011, 09:08 PM #10

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 47

Hi Ahtopahtel,

You don’t need a screw that long, try something like in the picture, you still get the travel needed but to half the price.

Or maybe like this.

-

01-16-2011, 09:58 PM #11

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 77

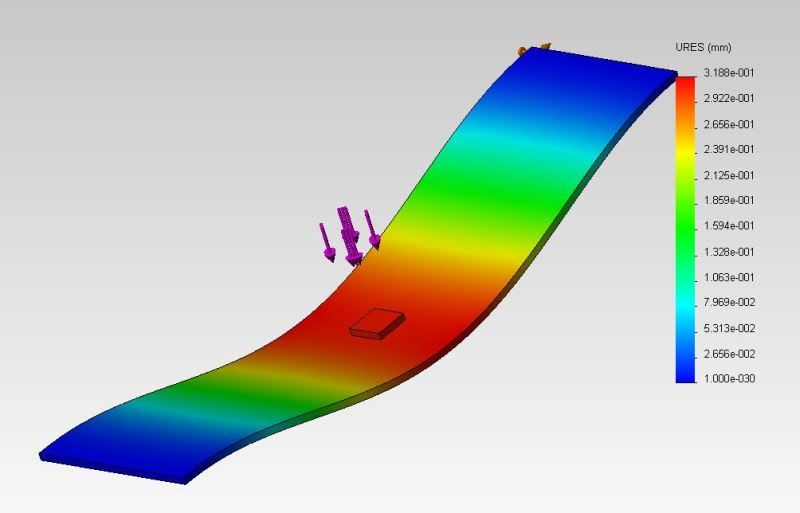

I think you some bracing is needed as well. Attached file show 6063 t6 1000mmx250mm 10mm thick. 10kg load on the centre block will deflect it 0.31mm... just to give some idea of what you are dealing with.

-

01-17-2011, 12:38 PM #12

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 15

Hey guys, thanks for the feedback!

There will be bracing, since the deflection would be to great indeed.

A very interesting idea on how to shorten the ballscrew, i'll give it a good think and see if i can somehow change the moving bed.

boomslang-can you do a simple drawing about your suggestion, i'm embarrassed to say i dont quite grasp the concept?

also a very important note, i decided to downsize the machine quite alot: the aim is to get 250mm for X-axis, 200mm Y-axis and 150mm for Z-axis. 2 reasons= the materials i get my hands on is that size and also i can create a more stable/rigid machine.

tonight updated system(smaller and supports included).

Similar Threads

-

New DYI Fixed Gantry Router Build

By DonFrambach in forum DIY CNC Router Table MachinesReplies: 291Last Post: 07-06-2015, 12:45 PM -

Fixed gantry machine, my own take.

By prcdslnc13 in forum DIY CNC Router Table MachinesReplies: 25Last Post: 02-14-2012, 07:30 PM -

Moving table fixed gantry build

By judleroy in forum DIY CNC Router Table MachinesReplies: 48Last Post: 12-15-2010, 05:11 AM -

fixed gantry

By eloid in forum DIY CNC Router Table MachinesReplies: 2Last Post: 01-29-2009, 11:20 PM -

Fixed Gantry

By Auzze in forum DIY CNC Router Table MachinesReplies: 1Last Post: 07-25-2004, 08:34 AM

Reply With Quote

Reply With Quote