So I am moving about 450 miles away from where I have lived my entire life. The move will include both my house and my business and involves setting up my shop on my property in a 1200 square foot shop. I have a 2007 Haas Minimill that is three phase but the new property only has single phase so I know a converter is going to need to be installed. I have been trying to explode my brain with info on converters, rotary and static, for about a month and think I am more confused about this then I was before reading and talking with my HFO along with multiple converter companies.

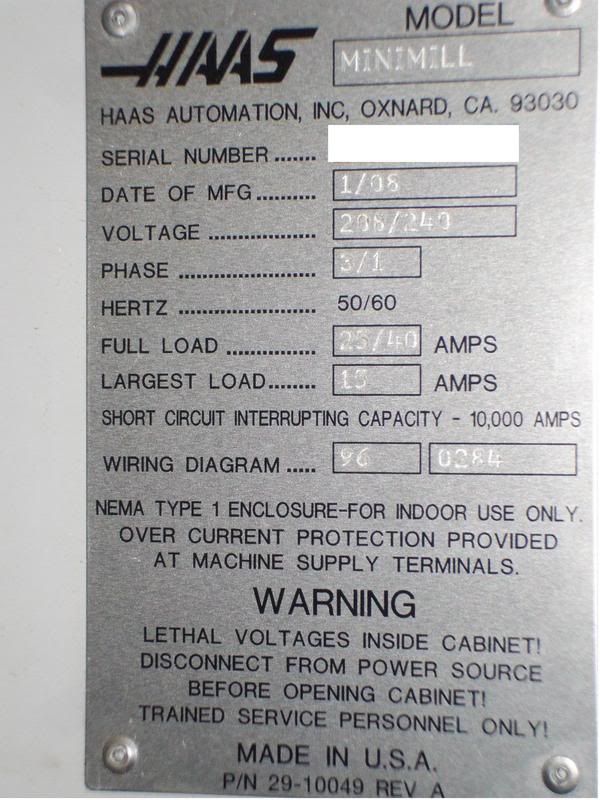

This is what the badge on the machine reads...

I know this model could be ordered with either a single phase or a three phase spindle and I ordered the 3 phase option. To me, the tag shows for both options, correct?

Now, next question. I need a phase converter and have talked to 5 companies and have gotten prices from $1,200.00 to $4,500.00 for a converter. To me that seems to be a pretty big window in pricing and once again, confusion has set in.

Third question. I keep reading about the balance between the three legs on three phase need to be with in 5% balance but my HFO install guy acted like I was speaking Greek when I brought it up. He said the transformer in the Haas will balance the power????

So, big question is, which converter do I need and what specs should I be going off of? This machine is my life blood so cocking it up or doing thousands of dollars of damage is not an option for me.

Thank you guys so much, I get so much great info off here

Thread: This sounds odd to me...

Results 1 to 20 of 36

-

01-18-2011, 07:42 PM #1

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

This sounds odd to me...

This sounds odd to me...

-

01-18-2011, 07:45 PM #2

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

One thing I forgot to add, I do a lot of rigid tapping with small taps (2-56, 2mm, etc) if that makes a difference.

-

01-18-2011, 07:57 PM #3

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 1702

I don't think you'll necessarily need the phase converter. First off, your plate says 3/1 phase. I think that means Three OR Single phase.

The telltale will be your spindle drive. Open the cabinet. Do you have a Vector Drive on the right side of the cabinet? If it doesn't say Vector Drive and your spindle is driven by an amplifier on the left side of the cabinet (mixed in with the axis amplifiers), it should run on single phase power.Greg

-

01-18-2011, 07:58 PM #4

Member

Member

- Join Date

- Mar 2010

- Posts

- 1852

Yup, you will need a phase converter if it is not single phase, rotary not static. A 20 hp will be fine, I run my VF-2 on one right now. The one listed below is from ebay and the shipping is free. The specs on it say +-2%, which will be fine too.

My first one I built myself and ran a whole shop with it for years, it was 30 hp. My current one I bought off of ebay.

They are easy to set up and run pretty quite.

If you have any further questions, just ask.

20 HP Rotary Phase Converter - CNC / Heavy Duty - eBay (item 310286988906 end time Jan-20-11 07:42:37 PST)

Cheers---MikeTwo Haas VF-2's, Haas HA5C, Haas HRT-9, Hardinge CHNC 1, Bother HS-300 Wire EDM, BobCAD V23, BobCAD V28

-

01-18-2011, 08:09 PM #5

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 1702

-

01-18-2011, 08:13 PM #6

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

-

01-18-2011, 08:15 PM #7

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

-

01-18-2011, 08:17 PM #8

Member

Member

- Join Date

- Mar 2010

- Posts

- 1852

Looks like single phase. And, I might add, very clean!!!!!!

MikeTwo Haas VF-2's, Haas HA5C, Haas HRT-9, Hardinge CHNC 1, Bother HS-300 Wire EDM, BobCAD V23, BobCAD V28

-

01-18-2011, 08:22 PM #9

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

How can it be both single and three phase? Also, is there any drawbacks to single phase operation? I thought I heard it would cog at lower RPM, run hotter, and have a little less power and torque with the single phase spindle so that is why I picked the three phase spindle???

LOL, I sound like a real idiot right now...

-

01-18-2011, 08:35 PM #10

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 6028

TM's and mini's can run single phase. They will use more current in single phase, but since all modern drives convert to DC, then back to ac, they work fine. According to your tag, 25 amps three phase, 40 amps single phase.

-

01-18-2011, 08:58 PM #11

Registered

Registered

- Join Date

- May 2004

- Posts

- 142

I would get the phase converter... it is cheaper to run. the rule of thumb i was told is always double the horsepower needed when you buy the converter i.e... mini mill hp (non super)= 7.5.. so buy a 15hp

DONT MIND MY SPELLING ... IM JUST A MASHINIST

-

01-18-2011, 09:00 PM #12

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 6028

Thats not always true. It will take power to run the phase converter. I'd bet it equals out.

-

01-18-2011, 10:01 PM #13

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 107

From an electrician: It will take a max of 25 amps for 3 phase or a max of 40 amps single phase. I read that label as convertable from 3 phase to single phase, but you should check with Haas.

-

01-18-2011, 10:13 PM #14

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 769

Call HAAS Automation

If it were me I would contact HAAS and make sure you get the correct information. It is a toll free call and can easily set your mind at ease.

I have a 2007 HAAS TM-1P with the 7.5 spindle motor 6000 rpm. I was told I could hook mine up either on 3 phase or single phase. I chose to hook mine up with single phase and it has worked perfect for me. I took a few pictures of my wiring in my cabinet a few weeks ago for a friend of mine. I will share them so you can get an idea how mine was wired for single phase operation. Of course you should get a licensed electrician to hook up your machine and follow the appropriate HAAS wiring schematic.

I too, do a some (over 1000 holes) rigid multi level tapping with a 3mm X 0.5 form tap in 6061 T6 aluminum and it works fine for me.

I have a home-built rotary phase converter that I use for other 3 phase equipment in my home shop. However, I decided not to purchase a phase converter as this was the only 3 phase piece of equipment I intended to purchase that would require a phase converter larger than the one I currently have.

The reason for my decision was that it would take a bunch of electric bills with substantial savings in each one of them to ever pay for the phase converter. Mine is a small garage workshop and I don't run my machine daily. Your mileage may differ as to your decision on whether or not to purchase a phase converter. i.e. how many machines you have that may need 3 phase current.

Good luck on your move and new home. Wish you the best of luck.

John2007 HAAS TM-1P OneCNC XR5 Mill Pro. Shopbot PRT running Mach3 2010 Screen Set, Super PID and PMDX Electronics.Check out my Gallery on: http://[email protected]

-

01-18-2011, 10:34 PM #15

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 1184

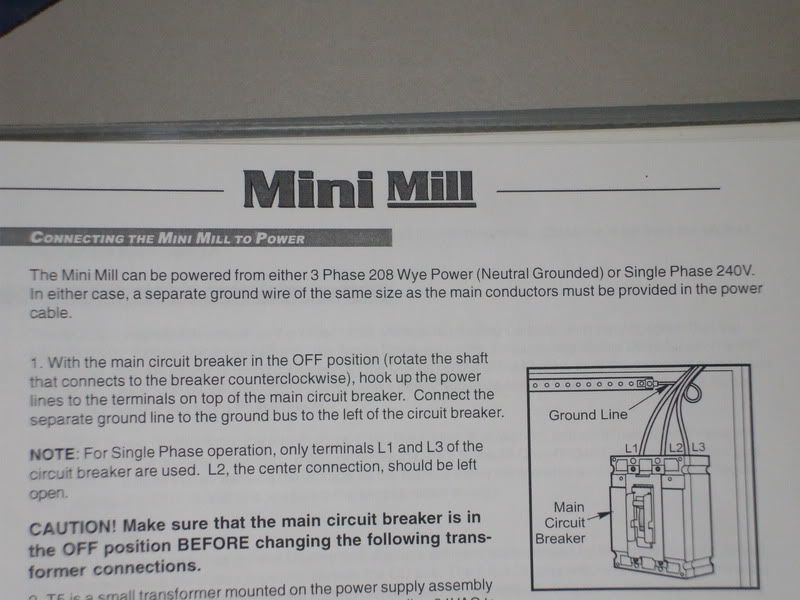

Follow the link for the mini mill manual addendum on the Haas website.

Haas Automation Inc. - CNC - Customer Service - Operator Manual Update

There is a section for installation that describes how to hook up to either 3 phase or single. Your machine will run fine on either one.

Good luck on the move.

-

01-18-2011, 11:28 PM #16

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 1702

Almost everything you heard about 3-phase vs single-phase was wrong for one reason: Haas machines run on DC power. The power comes into your machine, through that circuit breaker, through a transformer and then into that silver box on the right side (320V power supply). After that silver box, the machine is running on 320V DC power.

3-phase power will generate smoother DC. It will cost less to run IF you're already in a building with 3-phase service. If not, no big deal. The capacitors in that silver power supply do their best to fill in the gaps. The machine doesn't really know the difference and runs the same, regardless of which you use.

-

01-18-2011, 11:50 PM #17

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

Well, I had to take my son to the doctor this afternoon so I grabbed the operators manual for my Haas and started reading and this is what I found...

...which puts my mind at complete ease. The $3,500.00 I had budgeted for the converter and install can go into tooling and other goodies to help out around the shop. Maybe a DRO for the lathe and a new band saw. Might even find a nice flat screen for those lone cycle times

-

01-19-2011, 01:28 AM #18

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

When all else fails read the Manual:stickpoke

An open mind is a virtue...so long as all the common sense has not leaked out.

An open mind is a virtue...so long as all the common sense has not leaked out.

-

01-19-2011, 01:32 AM #19

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Eritex Inc.

It will run just fine 220/240 single Phase, the Mini Mills run both single or 3 phase

You need to run a 60amp 220/240 single phase supply

So you don't need a phase converter

If you were going to get a phase converter, Get a Phase-Perfect, they are the best & most efficient to run, but cost more to buy

There are no draw backs to running it on single phaseMactec54

-

01-19-2011, 02:38 AM #20

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 27

Similar Threads

-

Sounds of machines

By bunalmis in forum Stepper Motors / DrivesReplies: 35Last Post: 03-31-2021, 05:05 PM -

Wolfgang motor sounds bad

By frejohg in forum PCB millingReplies: 38Last Post: 06-13-2010, 10:22 AM -

Steppers very loud, sounds like siren on circles

By augustus c in forum DIY CNC Router Table MachinesReplies: 11Last Post: 01-12-2010, 02:30 AM -

Cutting circles sounds like a siren?

By mrcodewiz in forum Benchtop MachinesReplies: 2Last Post: 04-10-2008, 11:59 PM -

Stepper motor sounds and clicking

By Sanghera in forum Stepper Motors / DrivesReplies: 16Last Post: 11-07-2004, 06:42 AM

Reply With Quote

Reply With Quote