Learning to weld all over again at work today... Using some nice Miller welders.... This thing is about the size of my motorcycle!... I can weld pretty good with the crappy 160amp I have now...I've gotten used to it..... but this thing is just badazz!... Taking my welding cert test next week... They have some wicked Laser cutters as well... and will be getting a 5000watt model next month... I'm told about 1.5million worth.... I bet they dont let me play with it?...

On a good note.. Picked up a piece of 1/4" alum plate today to bolt to the underside of my gantry... and see if that stiffens her up!

Results 261 to 280 of 341

-

05-13-2011, 01:32 AM #261

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-13-2011, 01:43 AM #262

Registered

Registered

- Join Date

- May 2007

- Posts

- 250

Winegar,

Do you have THC with your machine ?

Mongkol

-

05-13-2011, 02:03 AM #263

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-19-2011, 07:48 PM #264

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 6

-

05-19-2011, 08:51 PM #265

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-19-2011, 11:47 PM #266

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Nice... So, do you have a way of putting the torch back on in the EXACT same position as before if it were to be knocked off? I only as as it would completely through off your touch switch even if you were off .01".... Look good though!!!

-

05-20-2011, 03:28 AM #267

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-23-2011, 12:22 PM #268

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 5

I`ve been following your post from first page, and there is a summary of question in my mind ;

Do you use air dryer on your compressor, hypertherm seller tell me the compressor air dryer can give the best result ( minimize the dross ) to filter the water before they get into plasma unit, and it cost for approx. US$ 2400…. Very expensive Huh……

If I saw your plasma unit, you are not using Hypertherm, why ?

Do you think change the plasma hand torch into a plasma machine torch can result a better quality of cutting ?

Somesays that X axis can use a timing belt, which is better ? timing belt or rack & pinion gear as yours ?

newbie question :

Ini this 4 x 4 table cases, Do we need an adjustable plate on the bottom of table legs in order to keep the table flatness?, for the big size of table i`m preety sure we need to attach the foot adjuster, but for 4 x 4 table, I need more opinion…

For Z axis, is it the floating Z from the tulsaturbo`s store, or you build it your self?

Have a planning to use MP 1000-THC or THC 500 ?? if the answer`s no, why ?

I`m realy sorry if there is repost question….

Thank you for sharing….

-Harry-

-

05-23-2011, 08:09 PM #269

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Harry......

Well I do have an air dryer but i'm not using it yet... That probably would help things a bit!... Maybe I will get on that in a few days... Cant afford a Hypertherm!... If i could... I would by one... till then, I'm stuck with the one i have.... But overall i'm pleased with it... and yes, I truly believe if i switched my hand torch to a machine torch, I would/could get better results as well!... Honestly, I'm not the one to ask about timing belts... Only ones i have ever messed with go on gasoline engines!...lol... But really, I'm not sure about that.... I am replacing my wheels for adjustable legs when i get everything finished and a place designated to put her!... Plates with Nut is already welded into place, just need to take the wheels off and put the adjusters on... I'm expecting no change... but who knows?.... Yes it is one of the kits from TulsaTurbo.... Quick and easy!.... I would like THC.... maybe late this summer... but what i have going on right now with my cuts are pretty good and really dont have to have it!...

Hope you have a good one and all,

Kelly!

-

05-24-2011, 01:06 PM #270

Registered

Registered

- Join Date

- May 2011

- Posts

- 34

hey winegar read your build through .... love it mate looks like its turned out really well for you other than the teething problems.... but hey these things happen looks like the machine came up really nicely, its a very similar machine to the one i hope to build a 4 by 4 foot system... except unless i hear back from PCB as to weather the ship international or not i might have to find some other rails

keep up the good work mate

keep up the good work mate

-

05-25-2011, 10:22 AM #271

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Thanks countrykid!... Hope you can get all the parts you need okay!.... If not like these, then they are so many other options, may require a little more work... but you will get it done!...

-

05-26-2011, 04:18 AM #272

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 33

Where's my rails?

I am duplicating winegars build here to the tee. Unfortunately, I do not have any rails yet. I have a beautiful blue table frame, a brand new PM45, licensed Mach3 that, again thanks to winegar, is controlling the trigger, and every other motor and part to finish the build. I ordered my rails May 4 from PBC. They were to ship tomorrow. I got a call from the distributor that the ship date has been moved to June 10th. Not a happy customer right now.

This is ridiculous in my opinion. Soooooo, there has to be another resource for these aluminum extracted rails. If you know of one would you mind posting? I would not do business with this company again. I am confident they will come through eventually, but it is not the kind of service I want. There is probably another solution for rails also that I will start researching. Like winegar, I will strive to keep costs down. FOr a plasma cutter the tolerances don't have to be that tight. A good engineer should be able to come up with something other than constraining ones self to one supplier.

Hats off to winegar for the time and effort he gives to everyone to help make them successful. He has certainly opened up new opportunities for me.

CHEERZ!

Jerry

Boise

-

05-26-2011, 12:00 PM #273

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Good luck on geting your rails. I went through the same BS about 2 weeks ago. In fairness I think my supplier dropped the ball somewhat and did not place the order on time, when I called pbc they had the order ready to ship but the date it was placed was 3 weeks past when i orderd.

As to alternate choices there are many some better some not, but i could not find any product made like pbc ivt rail at thiere price. I must say it was worth the wait my gantry had some play that affected cuts this stuff fixed that. Good luck

-

05-28-2011, 05:20 PM #274

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

winegar did you put 1/4" alum plate on the bottom of the rail to eliminate flexing your gantry?

To all your trying to get PBC rail the problem is with $200 minimum rule that PBC have and your local supplier wont tell your that because they want to make some $$$ i get my rails in 10 days i pick up by my self to eliminate shipping time but to do that your need to have register company because PBC will make problems to sell to a regular walk in customer. You have to know how to fill in PBC order form which must include all the necessary information like what hole pattern do you want etc. i recommend get centered pattern.

-

05-29-2011, 02:11 PM #275

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I placed the 1/4" Alum plate on top... and that took care of most of it.... also, I welded my slates together, just a tack weld in the center of each one, where the two meet.... that took care of a lot of movement too... I plan this week to build adjustable feet for it as well, instead of the wheels!...

Will have a few photo's to put up here in just a little bit!...

-

05-29-2011, 02:57 PM #276

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

This is before i cleaned it up.... will post a finished photo later today!

CNC Plasma Table Build :: POW-MIA Video video by warchildzx7 - Photobucket

-

05-29-2011, 04:53 PM #277

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 227

Awesome!!!

Very Nice Winegar...

Looks like it turned out pretty good, How is your machine doing? Do you have it dialed in yet??

BTW would you be willing to share that dxf file of the POW MIA?? Thanks

-

05-29-2011, 09:50 PM #278

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

pow/mia

I'd like a copy of that file as well............jb

-

05-29-2011, 11:37 PM #279

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

thx winegar pictures will help a lot for that upgrade

-

05-30-2011, 10:29 PM #280

Registered

Registered

- Join Date

- Apr 2011

- Posts

- 33

Nice cut Winegar!!!

Where are the holding tabs for the text added? Deskengrave? Special font? Sheetcam?

Linktiger: The rails were well over $200. To buy direct I was told I needed to promise at least $2000 in orders for the year. There wasn't much price difference between the PBC quote and the distributor. PBC said the distributor gets a price break and that was why the prices were close. I just want my freaking rails.

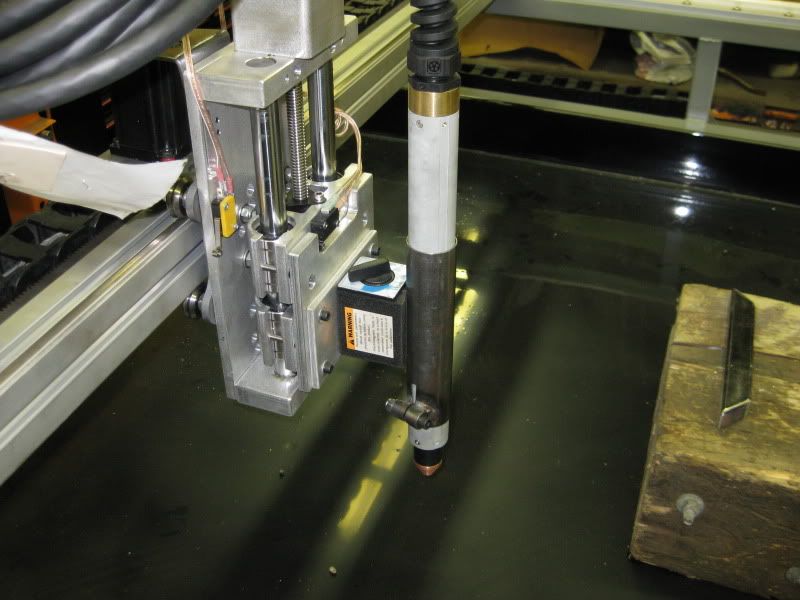

Here's my Z ready to go:

Similar Threads

-

New Free CNC Router Plans 12" X 11" x 4", Build for $220 or $105

By Modular CNC in forum Open Source CNC Machine DesignsReplies: 1Last Post: 11-25-2013, 12:57 PM -

very large 3-axis 72"-55" project starting

By haylspa in forum Benchtop MachinesReplies: 7Last Post: 06-05-2013, 09:52 PM -

Table top MDF build - "The Home de-bot"

By JohnnyVegas in forum CNC Wood Router Project LogReplies: 31Last Post: 06-25-2011, 01:55 AM -

Anyone bought a "plasmabot"???... Feedback???

By winegar in forum Want To Buy...Need help!Replies: 5Last Post: 02-02-2011, 04:41 AM -

First build 8020 60"x24"x5" Board Shaper

By dlyork in forum DIY CNC Router Table MachinesReplies: 18Last Post: 09-07-2010, 02:32 PM

Reply With Quote

Reply With Quote