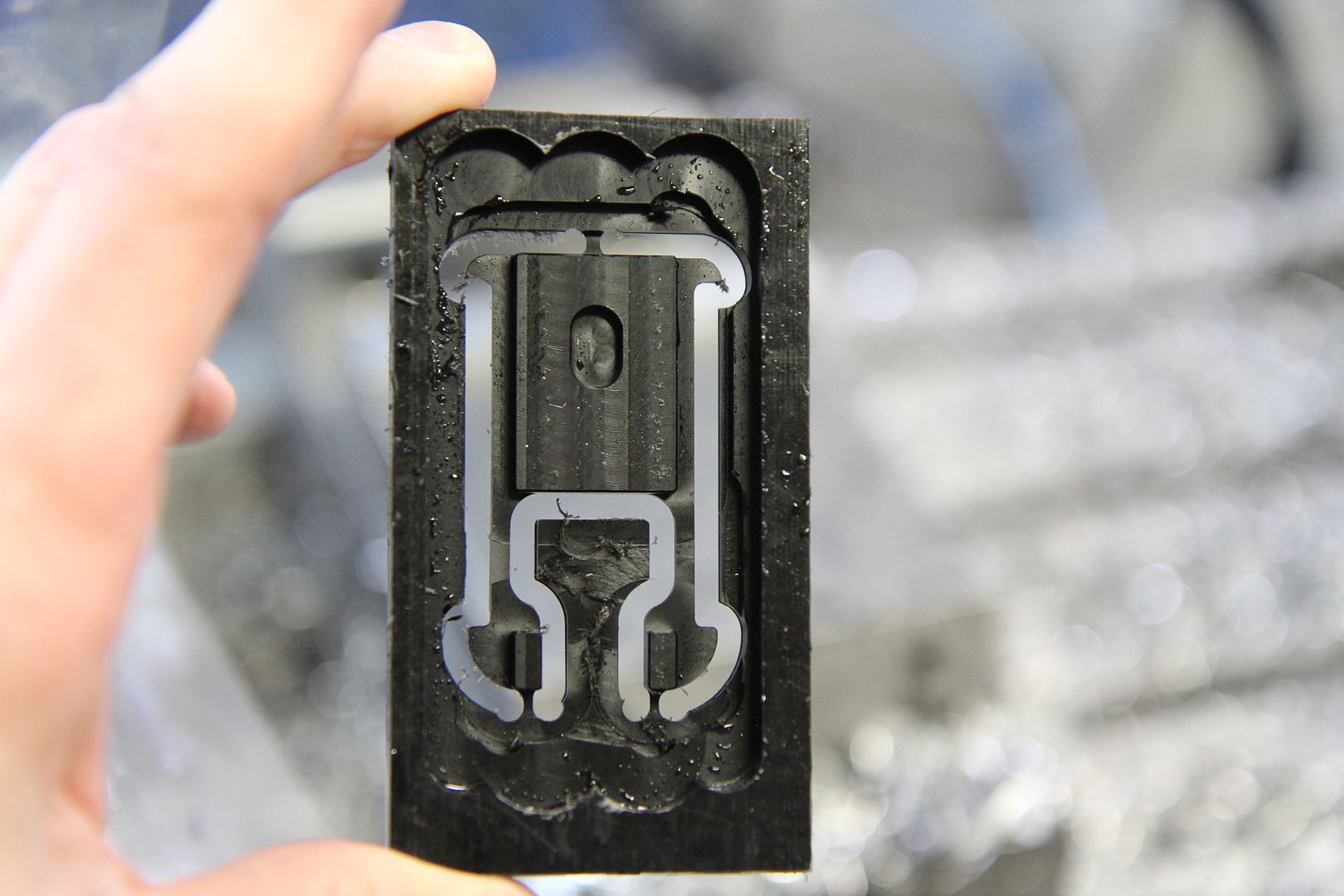

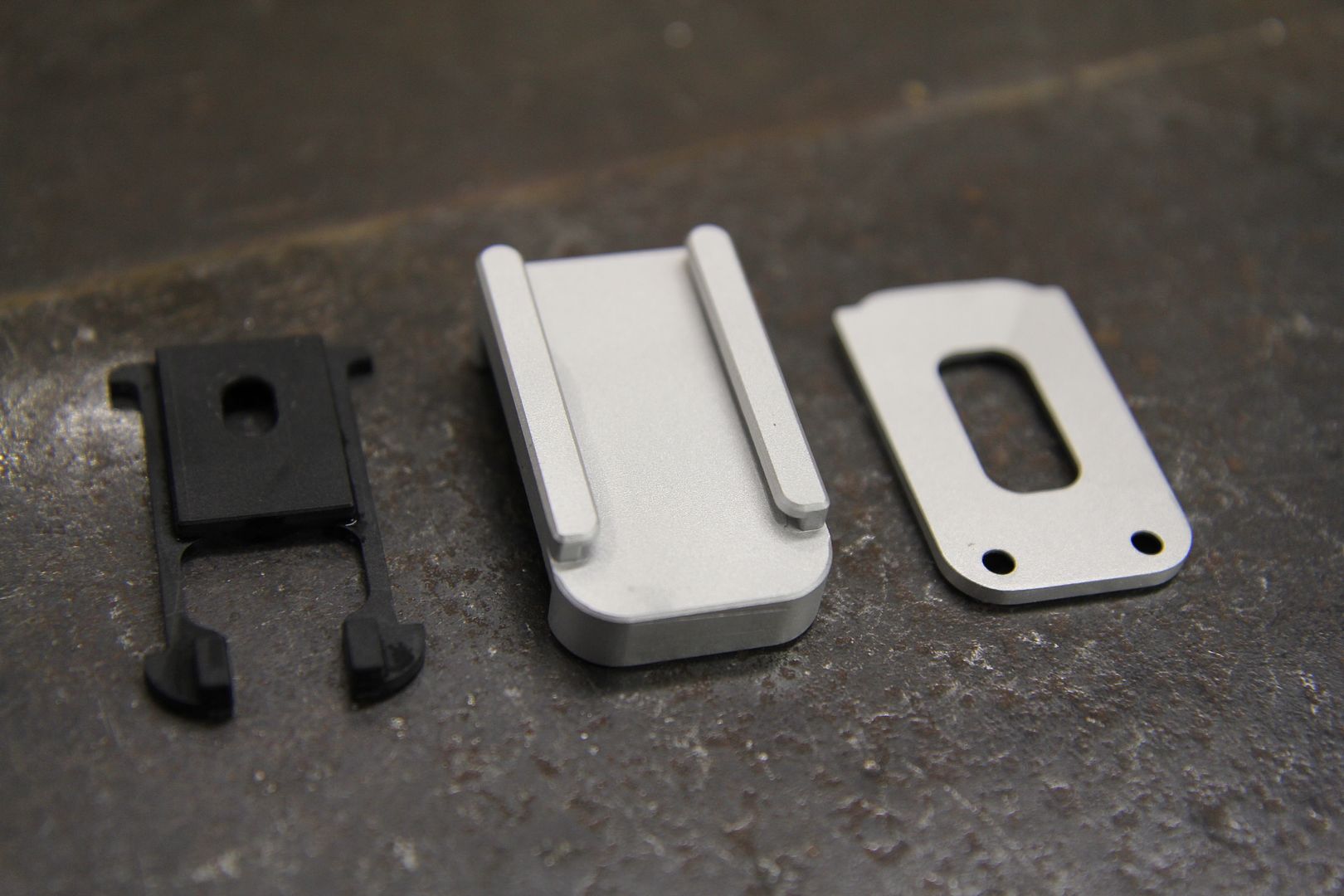

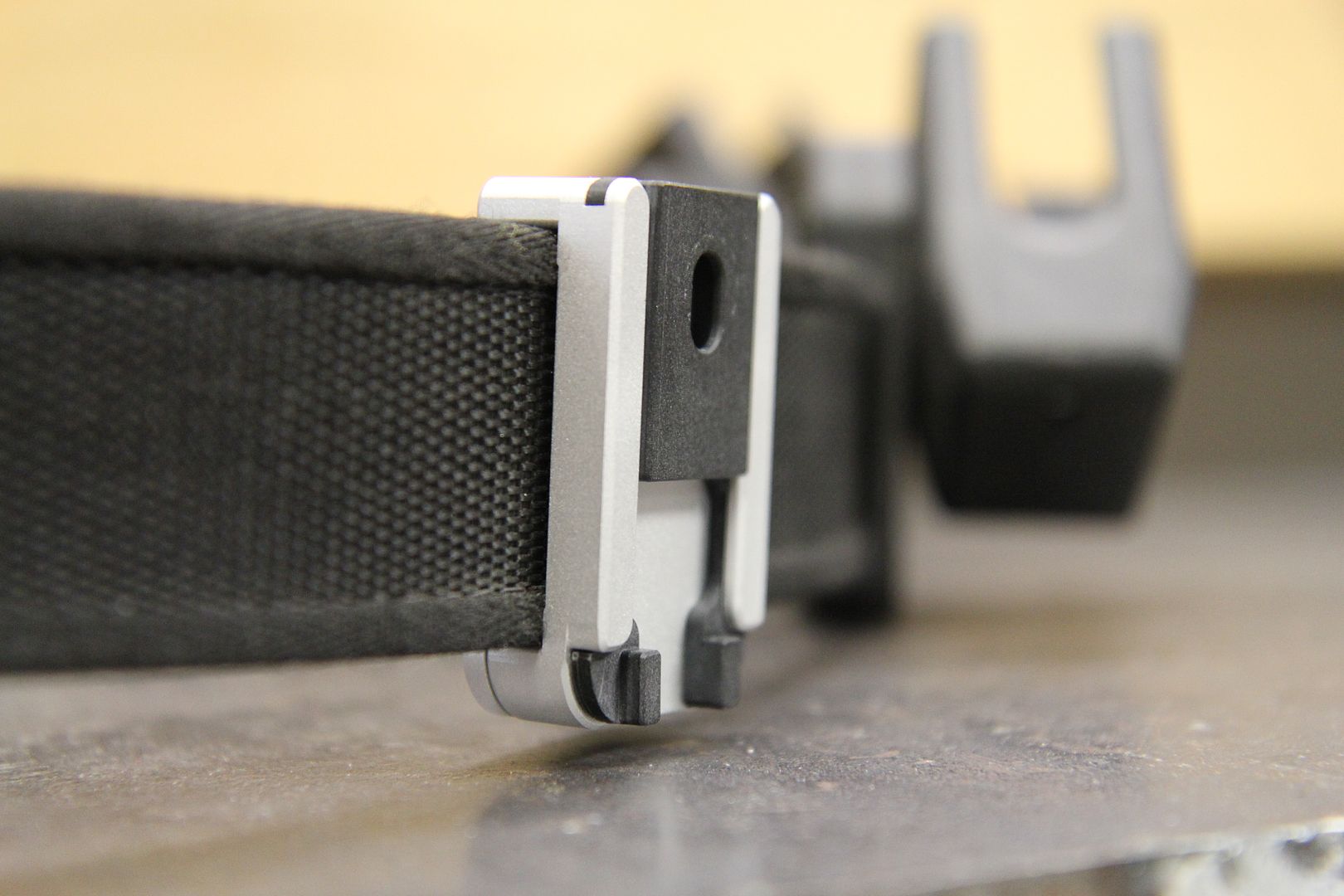

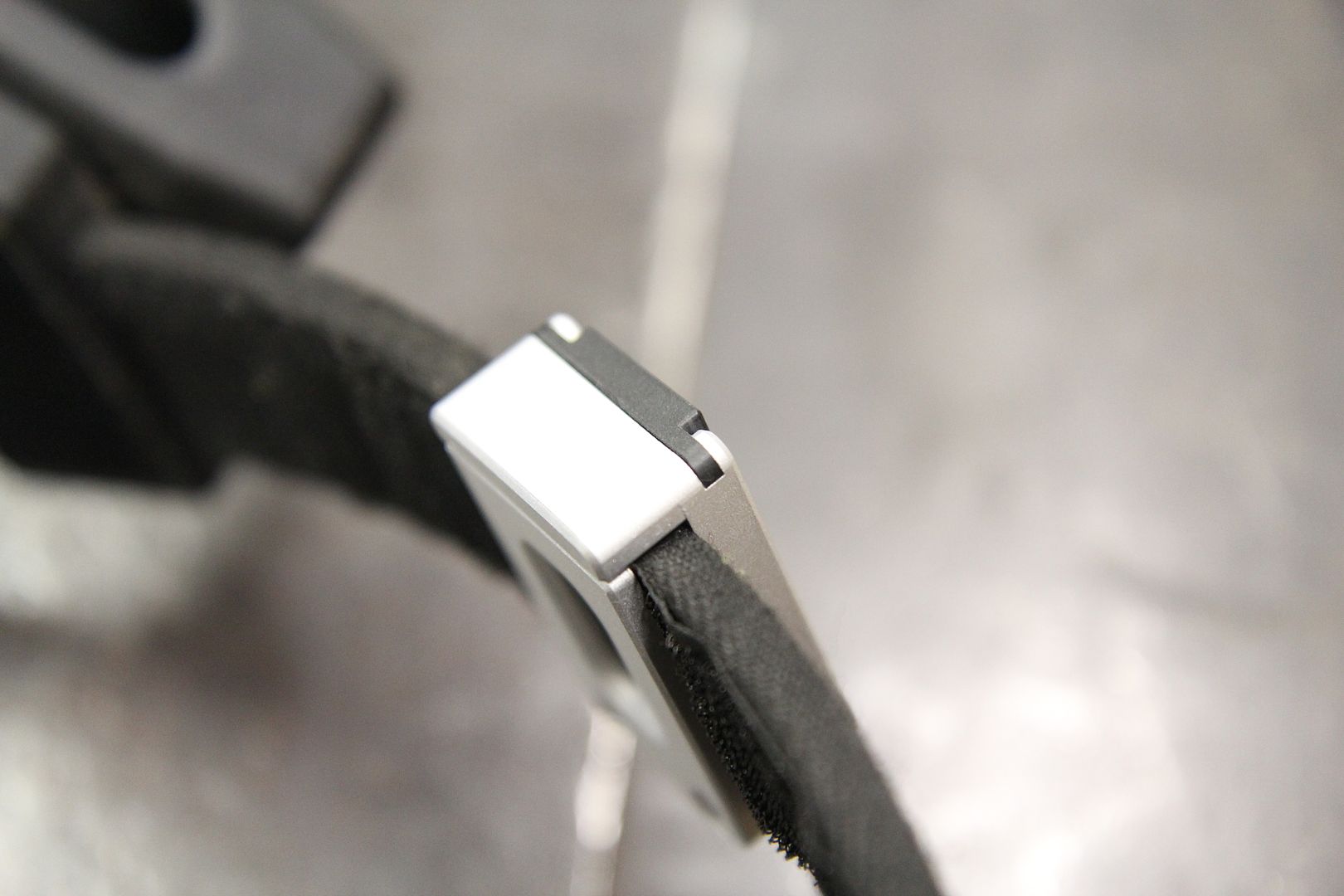

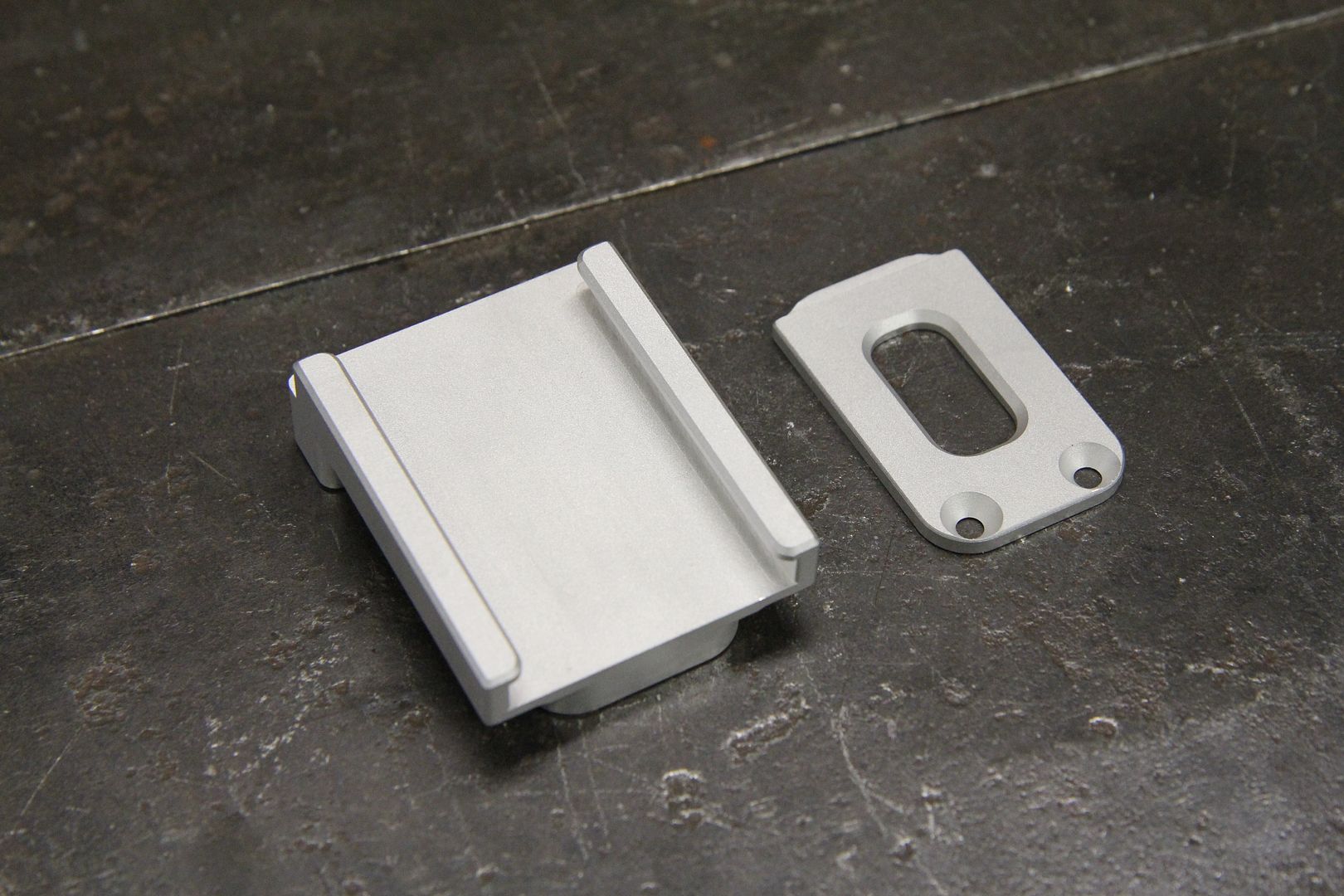

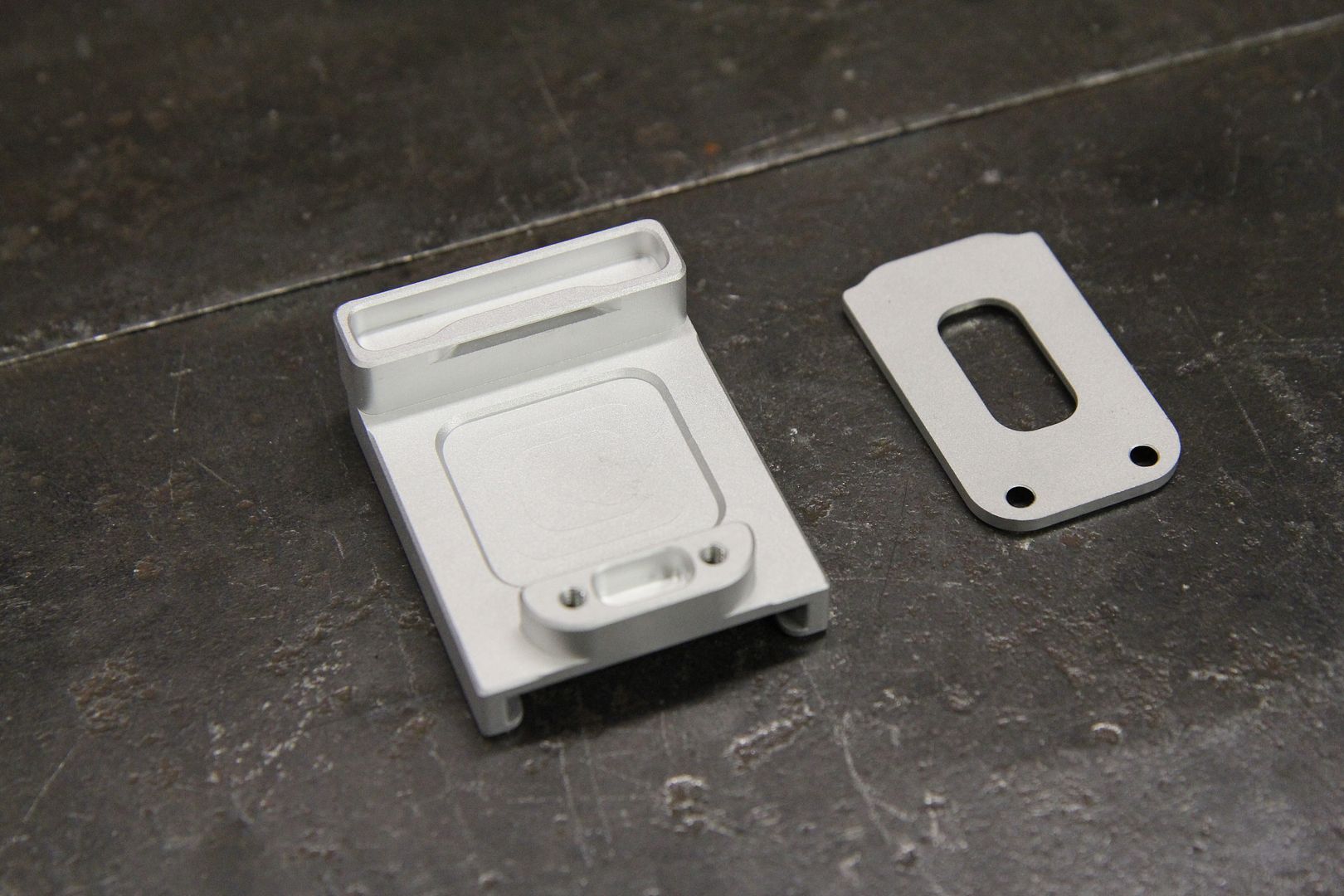

Back to doing some work on my machine. Did some delrin parts. I ended up scraping the first try when it broke trying to face off the carrier stock on the 2nd op. So I ended up doing it with tabs.

Had the machine cutting at 195IPM, which was fun. But Mach was giving me a random fault until I rebooted.

Some video.

https://www.youtube.com/watch?v=o7RoEkE8c9s

Thread: PM-45 CNC Conversion (RF45)

Results 801 to 820 of 874

-

03-02-2014, 10:52 PM #801

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

PM-45 CNC conversion built/run/sold.

-

03-03-2014, 04:41 AM #802

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

PM-45 CNC conversion built/run/sold.

-

03-03-2014, 05:01 AM #803

Registered

Registered

- Join Date

- Nov 2003

- Posts

- 287

Outstanding craftsmanship.

-

03-03-2014, 05:09 AM #804

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 962

Very nice assembly!

I've discovered I really like machining Delrin parts .. and also learned as you did, the right approach makes the difference!

Like the finish on aluminum too, is it bead blasted?

Gary

-

03-03-2014, 06:15 AM #805

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Yeah it's bead blasted.

PM-45 CNC conversion built/run/sold.

-

03-03-2014, 10:56 AM #806

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

Very cool!!!

-

03-04-2014, 04:18 AM #807

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 340

Jid, every time I watch your videos I'm curious about the vises I see. They look like they are about 3 inches. Where did you get them? I'm also curious what cutters and S&F you were using. They did a pretty good job on the aluminum and left a nice finish.

-Freeman

Sent from my Xoom using TapatalkCRP-4848 CNC Router, CNC G0463 (Sieg X3) Mill, 9"x20" HF CNC Lathe (current project)

-

03-04-2014, 05:27 AM #808

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Those are el cheapo Shars 4" CNC vises. They are crap, but cost nothing, and I wanted something cheap as I don't plan on spending too much more time with this machine. Aluminum is cut with a Maritool carbide tools, 3 flute for the 1/2" and 2 flute for the 1/4" and 1/8". Spindle is always at 6800-7200 RPM for roughing and 5000 RPM for finish. Roughing is .060" stepover up to about 1" deep, and around 90 IPM. The video is shallower depth and stepover up to about .080", feeds were knocked down to between 75-80 IPM just because I didn't have time to screw with a tool pulling out. I find I risk pull-out when I push around 4 MMR or higher.

PM-45 CNC conversion built/run/sold.

-

03-14-2014, 11:03 PM #809

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Jid, saw your beautiful build show up on craigslist. Time for a new machine?

Wish I could afford yours

-

03-15-2014, 12:05 AM #810

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 194

-

03-16-2014, 12:02 AM #811

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Yeah - time for the real deal.

Price is looking to reflect what a used Tormach typically sales for in the Seattle area. I'm thinking that at that price I will likely throw in all my tooling and my super quiet air compressor. We'll see.

If I can validate that my scope project is going to be a good seller than I'll buy a new Brother, otherwise I'll settle on a used Super Mini Mill.PM-45 CNC conversion built/run/sold.

-

03-16-2014, 01:33 AM #812

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 3

Thanks Jid2 for the very informative build, I just got finished reading trough all your build thread and can not thank you enough for the inside info to the capabilities of the RF45 CNC build as I was about to embark on the same path with the Enco RF45 I have.

Good luck with your new endeavor with a store bought ready to use CNC (I am envious of you )

)

Bill in SE Idaho

-

03-17-2014, 07:21 AM #813

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

For comparison, here is video of cutting a part similar in features, but larger in size to the ones I shared in post #795. Parameters are in the description of the video, but roughing is at 250 IPM and between .125" to .20" stepover, at 14K RPM.

Enjoy. This is what I need for the garage.

CNC Machining Brackets on Brother TC-S2Dn-O with HSMWorks - YouTubePM-45 CNC conversion built/run/sold.

-

03-17-2014, 12:17 PM #814

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

I'll take one! Haha

-

03-17-2014, 04:24 PM #815

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 3

-

04-28-2014, 10:51 AM #816

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 64

Re: PM-45 CNC Conversion (RF45)

I know this is super old but do you have the dimensions for the length, width and pitch or a drawing of what you ordered from linearmotionbearings2008?

I haven't received my machine in yet and I wanted to order all the stuff ahead of time so any information would be greatly appreciated

ps your machine looks amazing!

-

04-29-2014, 12:46 AM #817

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Re: PM-45 CNC Conversion (RF45)

I could share what I used, but honestly its only useful if you do my conversion. Youd be best served to design what you need and order accordingly.

PM-45 CNC conversion built/run/sold.

-

04-29-2014, 01:22 AM #818

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 64

Re: PM-45 CNC Conversion (RF45)

Judging by your design I would be a fool not to follow in your foot steps

The only slight possible issue I see is that I ordered the PM-932M however I believe there is only a difference in the Z

I wouldn't mind paying for the information as well

-

04-29-2014, 01:36 AM #819

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 194

Re: PM-45 CNC Conversion (RF45)

the primary issue is the overall dimensions will vary even though they look similar. perhaps starting your own thread and measuring out the dimensions of your machine the way it sits now, will help everyone including yourself design a suitable approach to converting your machine. that will also serve to help you problem solve other machining tasks in the future.

-

04-30-2014, 09:42 AM #820

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 64

Re: PM-45 CNC Conversion (RF45)

Hi Dracozny,

I understand where your coming from but as I stated I don't have the machine in yet as I still have another 6 weeks till it comes in and I wanted to purchase everything for the conversion ahead of time.

Matt from Quality Machine Tools stated that the 932 is exactly the same except the 932 has a little less travel because there are slight casting changes to accommodate the powerfeed connectors for the x and the z.

None the less any information jid2 could provide me would be really helpful and get me near the right ball park to order my ball screws ahead of time.

Similar Threads

-

Starting another DMM conversion, IH RF45 clone

By ayorba in forum Dmm TechnologyReplies: 0Last Post: 06-08-2014, 02:36 AM -

HM45 Conversion (Yes another RF45 clone)

By slipery in forum Benchtop MachinesReplies: 10Last Post: 12-19-2011, 12:07 AM -

Am I Looking for NOISE trouble (RF45 Conversion)

By Bird_E in forum CNC Machine Related ElectronicsReplies: 6Last Post: 03-30-2011, 07:37 PM -

AC Servo on RF45 Conversion help

By Maglin in forum Servo Motors / DrivesReplies: 5Last Post: 02-23-2011, 03:57 PM -

RF45 clone CNC conversion

By GMitchell in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 09-08-2009, 05:50 AM

Reply With Quote

Reply With Quote