Thanks Jay, no discouragement at all.

I have been 3D printing for about 10 years now, just not with these fantastic smaller machines. This stuff intrigues me because I do "get it" and I love the whole community that is building up around something that I, and obviously you, are passionate about. That's why I want to push the envelope further here and start combining processes - after all, most real world objects are a result of multiple materials and processes. Isn't the goal of the reprap to one day build itself? That will require more than extruding abs, no matter how accurate you can get it, I guarantee it. But that's just my personal opinion of course...

Thread: CNC router to 3D printer

Results 61 to 80 of 84

-

05-03-2012, 07:49 PM #61

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 19

DPRouter 4'x8'x8", Rockcliff Driver, 425oz. Nema23, 2HP, Belt drive xy, Acme z,

400ipm rapids, 120ipm safe cut

-

05-03-2012, 11:55 PM #62

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 1137

You know, that's seems like the one thing these things are used for...printing improvements for themselves. I know I was always looking for the next upgrade to tweak performance, or neat desk toy

I just love to watch automation. If CNC milling/routers were as quiet as FDM I'd be cutting more

I just love to watch automation. If CNC milling/routers were as quiet as FDM I'd be cutting more

-

05-14-2012, 04:02 AM #63

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 59

anyone got some pics of their cnc with a print head attached? Ive been messing with this idea for awhile now.

I just finished a wades extruder for mine...

I need to get another nema 17 stepper, i have like 10 but either the shafts are round or to short. I also need to build a hot end. Anyone got a preference? I dont have a lathe so its gotta be fairly easy to make without one. Not sure how ill control the temp of the hot end or a heated bed.

Anyone got some pics for some ideas?

Thanks

Mike

-

05-14-2012, 04:08 PM #64

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 19

-

05-24-2012, 03:09 AM #65

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

-

05-24-2012, 03:20 AM #66

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 313

You can find an extruder complete with a nozzle on Ebay, and for electronics try "Generation 6" or RAMP's, they are the newest.

As for the firmware and the CAM software try Sprinter found on the RepRap Wiki or complete here The First Sprinter Easy Install Program and it's $4 3d printer software for windows

-

05-24-2012, 03:24 AM #67

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 313

A regular NEMA will work, you don't need a special shaft, just hob the bolt using a drill or hacksaw.

You do this by cutting a grove into the side of the bolt.

I am not sure what software or hardware your using but if your looking for Firmware for Arduino boards try Sprinter The First Sprinter Easy Install Program and it's $4 3d printer software for windows

-

05-24-2012, 03:48 PM #68

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 19

-

05-24-2012, 04:31 PM #69

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 59

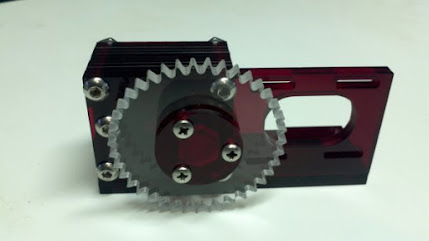

very nice setup, I'm still a ways off from printing anything, that extruder and hotend look solid! Was it based on something else or your own design?

I was thinking a solid metal extruder would be more durable than the peek or ptfe route ive been modeling after but then Id have the heat to remove before it melted the acrylic extruder body.

I figure ill build a couple before I finally get it right, its a fun side project for me at this point anyways.

-

05-24-2012, 04:34 PM #70

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 59

I just noticed in the last pic under your print bed. Is that one of those heated reptile mats?

-

05-26-2012, 06:10 PM #71

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

No, its a heated rubber mat like the ones listed in the link below:

McMaster-CarrMy Blog

http://www.needfulthings.net/tulsaturbo/myblog/index.php

-

05-26-2012, 06:14 PM #72

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

-

05-26-2012, 06:15 PM #73

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

-

06-10-2012, 01:48 AM #74

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 128

Very interesting, this will also be my altenative route to convert my current cnc machine to 3D Printer.

Im using Gecko G540 Stepper Driver with 48V 7A Power Supply. My 4 stepper motors are all 387 oz-in rated 50V 3.5A. I can use my A Axis for my extruder but the motor attached is 387 oz-in stepper motor. Can I attach 2 pcs. Nema 17 67 oz-in Stepper Motors 50V 1.68A by replacing 387 stepper motor connecting to my Gecko G540 Stepper Driver system?

-

08-14-2012, 02:36 AM #75

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 0

-

08-27-2012, 04:35 PM #76

Gold Member

Gold Member

- Join Date

- Jan 2007

- Posts

- 175

What I mean by independent is, the nozzle heat control is just a simple manual control, (independent from any type of computer control)

I guess " manual heat control" would be a better term to use

For heat control I am using an AC transformer and a standard light dimmer to adjust temperature, you can get some detailed info here

this is a picture of my complete setup, (other then motor driver, and fan power supply)

Rockcliff Machine Inc.

http://www.rockcliffmachine.com

-

08-28-2012, 01:31 AM #77

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 65

-

09-26-2012, 11:31 PM #78

Gold Member

Gold Member

- Join Date

- Jan 2007

- Posts

- 175

I am using an AC 8V @ 6A to drive the gage and length of nichrome on the hot end, but before you decide on a new trans. check NichromeCalc for the exact one you need with your wire gage and length, they are very easy to fry, when under-rated, but once you get the right one they last forever.

Rockcliff Machine Inc.

http://www.rockcliffmachine.com

-

11-03-2012, 08:26 AM #79

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

-

11-03-2012, 06:08 PM #80

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 313

I just wanted to note that the "easy-driver" with Arduino would work fine for adding another axis for printing.

The "G540" is a driver stand alone.

The "A4983" is a driver and will work but not with the Arduino stand alone and is usually used with 3D printer PCB's like "RAMS", this driver requires another IC to work properly.

Also just because the driver can provide 2A doesn't mean it will suddenly damage a motor, it just means that it can provide that amperage if needed.

The Voltage used that matters.

Hope this clears things up a little.

Rob

whatisacnc.com

Similar Threads

-

Building a cnc router with an old printer and an old scanner

By codemaster in forum Open Source CNC Machine DesignsReplies: 16Last Post: 09-16-2013, 03:10 AM -

router/3d printer 1x0.7x0.3meter modular design

By watanabe in forum DIY CNC Router Table MachinesReplies: 12Last Post: 06-05-2011, 03:58 AM -

Converting a laser printer into a 3d laser printer

By João Carimo in forum Uncategorised MetalWorking MachinesReplies: 22Last Post: 04-30-2011, 09:56 PM -

Converting a CNC router into a flatbed printer

By d_chappell in forum DIY CNC Router Table MachinesReplies: 10Last Post: 01-11-2010, 06:10 AM -

Printer for PCB ?

By WayneHill in forum CNC Machine Related ElectronicsReplies: 18Last Post: 10-05-2005, 06:42 AM

Reply With Quote

Reply With Quote