Hello

First off i apologize if this isn't in the right forum/thread area,I'm new to this sight and still trying to find my way way around.

I like many of you have decided to build my own CNC system,jeeze i thought it was going to be simple,some stepper motors,a control board,a pc and bam! but nooooooooooo! its a lot more complicated as i have found out.

Ive ran into some major issues that i was wondering and hoping very much you guys could help me with.

I have settled on the following for my needs

Nema 34 step motors @ 1269 ozin of holding torque

Parker Compumotor E-AC series drivers.....

Parker Compumotor OEM300 AC power module.

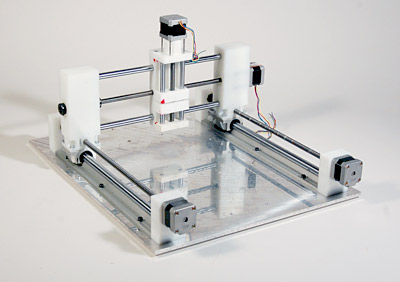

Zent toolworks CNC carver or

Lumen Lab micRO-Kit......but modified for a custom size/ application.

That's as far as i have gotten,The only Parker compumotor E series is some I found on ebay @159.99 each+ shipping with 34 size motor with 8:1 ratio gear head and electro brake)and E SERIES AC powered driver....i want the DC version but just cant find them anywhere.(mainly cause AC confuses/scares the crap outta me)

I have been having a very nasty time trying to find a compatible controller board to go with this system as well

Thats why i have come to this wonderful sight to ask.beg and plead for someone who knows alittle more about what i have selected and what else i may need

,i know that i will need break out box for the drivers.

i will also need a controller board,still looking

right now i have the Parker Compumotor OEM300 power module chosen to power the drivers,but that in and of itself is confusing me. here are the specs on the engine

* Size 34 frame

* Static Torque: 1269.67oz-in. (8.97Nm)

* Rotor Inertia: 14.8oz-in2 (2.7gc-cm2)

* Drive Current peak/RMS: Series 3.13/2.21A; parallel 3.8/2.47A

* Detent Torque: 50oz-in. (0.35Nm)

* Gearbox Torque Rating: 50Nm

* Output shaft: 20mm w/ key

Whats confusing me is this

i haven't seen anything telling me if the 34 size motor is AC powered,is it possible that the E-AC micro stepping driver is AC in and of itself but converts AC into DC to power the Step motors?

Also if i use the OEM300 Power module does it have to be hardwired into my house's AC line by directly connecting it to the wires? some breakers will ineffably blow right?

As for the actual CNC machine i was going to use? well i was going to use something akin to the Zen Toolworks CNC engraver or LumenLab mIcRo Kit,but custom made by myself and on a fairly larger scale.(that is if i can get this Driver/motor,Controller,Breakoutbox problem straightened out.

i really like the motors ive selected because they have the highest torque Ive seen of any motor (baring the $230 each nema 34's) on ebay. i was going to use Vexta 5 phase steps but the drivers themselves are just outta my budget so i went with combo deals.

If anyone out there in CNC land is familiar with Parker Compumotor products ,especially their AC products,can you gimme a post i sure could use the help.

or if you have any better ideas how i can still make a high torque CNC table top machine or know of of better more affordable parts,please dont hesitate to drop me a line.

thank you in advance for any help,it is sincerely and greatly appreciated.

Keith.

Thread: My CNC DREAM/NIGHTMARE!

Results 1 to 20 of 165

-

03-10-2011, 12:24 PM #1

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

My CNC DREAM/NIGHTMARE!

-

03-10-2011, 03:01 PM #2

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

I'm no expert, but it looks like you'll tear your machine apart (or I should say it will tear itself apart!) with those specs!

-

03-10-2011, 03:14 PM #3

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Yes its alittle strong,but i plan on making it alittle bigger than a normal table top CNC carver, 48x48,or 24x48 i still haven't worked out the desgin in my head as to how big i want it,i know how i want it to operate and look,just haven't decided on a size.

ive got some VEXTA PK26602-A's with drives on stand by order that if i cant find the Parker compumotor parts i want at the price i want then i will make a drastically toned down system,the Vexta Pk26602a only have around 10.3 lb-inch of holding torque and i can get 3 for 100 bucks drives ad controllers are cheap too,for older models newer ones still run 500 and up.

-

03-10-2011, 07:05 PM #4

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Hi,

If your going to that expense then I wouldn't bother with steppers and go straight for servo motors have a look here Motion Control Products - DMM Technology

Everything you need in 1 package very powerfull and accurate.

Why so big on the steppers.? Don't fall into the bigger is better trap because often with steppers it's counter productive. Larger steppers run much lower RPM's this can often be to the detriment of the machine depending on what you want to do with the machine. . . What do you intend to do with the machine.?

If your going to use these large steppers then you need to make sure they are matched to the right drive system IE Ballscrew, R&P etc that will enable you to get your desired needs. Often these needs revolve around what you intend to do with the machine.

My advice would be sit back a little before purchasing anything, think long and hard about the work it's going to do. This will then lead you to the right components for the machine, just buying big is very often a mistake and can limit your machine not improve, It's also a waste of money.!!

Give us some idea of the size you require and the type of work you intend to do and i'm sure between us we will point you in the right direction to get the best performing machine without getting silly on the wallet.!!

Regards

Dean.

-

03-10-2011, 07:58 PM #5

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Thank you for your response it is very much appreciated.

Well mainly im going to be doing alot of aluminum and some thick polycarbonate milling in it, perhaps some wood and when i get the chance and knowledge id like to convert to a laser of some sort for Laser cutting.

im glad you told me that bigger wasn't better cause to be honest i didnt know much about Holding torque and just saw that 1269ozin holding torque and was like "ok that should be enough" and thought it would be fast as well

Ive been reading all i can about stepper motors and drivers and controllers and break out boxes and the more i read the more i get confused.there is so much data,I've practically had to teach myself physics in the last 3 months.

The size of the table id like roughly to be about coffe table sized ..48 inches long, roughly 24 inches wide with a x axis travel of 8-12 inches. Ive been studying the Zen toolworks CNC wood carver,The Fireball V90,and the Lumenlab miCro Kit,with my thoughts leaning more to the micRO-kit because of its simplicity certainly not its cost at 700 bucks and was going to reverse engineer it from there. see enclosed image

i figured Neam 17's would be too underpowered for what i want,i plan on milling some fairly large pieces of aluminum and polycarb ,so i started studying Nema 23's...got quite a few vextas in my ebay favorites. Then i stumbled across Nema 34's.I was already set on a 24-48v DC Vexta system using 23's,but when i started reading the specs on that Parker Compumotor (50,800 microteps!) i figured that would give the pretty good resolution,that is if im thinking correctly that the tinier the step the higher and finer the detail.

My budget is tight ,i only get paid once every two weeks so it would all be basically piece by piece (though i have found all the linear motion rod,linear bearings,and rod supports as well as Acme thread rod on ebay for very good prices.Plus 25lbs of aluminum for 50lbs to make end pieces, I have a Unimat SL1000 Ive converted into a bit bigger of a milling machine that what it was stock its manual but i think it can help me with that.)

Right now im just looking for something that is fast,accurate,reliable,not too terribly complicated ,im a pc repair/Teleco tech so im not exactly illiterate on Computer stuff .

The thing is i just don't know what to choose for my motor,controller,driver.I see these kits on ebay out of Hong Kong and sometime the USA for 3 and 4 axis cnc router kits offering 3 and 4 engines,driver/controller and power supply sometimes with a copy of Mach3 for as high as 800 and as low as 180 .Nema 17's,Nema 23' and Nema 34's available.but im just not sure of there resolution ie if 1/16 micros stepping will give me the detail i want

(i want to do do a lot of picture transfer engraving as well as milling of scope mounts,air soft gun parts.and parts needed to make an even bigger CNC machine.)

again thanks for everyone's replies,

Keith.

-

03-10-2011, 09:38 PM #6

Registered

Registered

- Join Date

- May 2010

- Posts

- 0

I am going to use servo package from DMM technology, the performance is very good. I will post the result later.

-

03-10-2011, 09:43 PM #7

Member

Member

- Join Date

- Apr 2004

- Posts

- 5737

Why use gearbox motors?

They will introduce backlash, which is not exactly what you need. And they trade speed for torque, although it seems you've got plenty of torque already and need more speed.

Instead of spending a bunch of money on Ebay on miscelleaneous motors and drives, I'd say find someone who has designed a system for the sort of machine you're building, and who will support it after the sale. It's important to match the motors and drives, and to make sure they give the kind of performance you're looking for (and holding torque isn't the most important factor.) If those machines you've illustrated your post with are the sort of thing you're planning on building (scaled up), I doubt you'll be able to cut aluminum very effectively - those unsupported rails just aren't rigid enough.

I don't think there's such a thing as a AC stepper; all the ones I've ever heard about are DC. There are plenty of AC servo motors, though...

Andrew Werby

ComputerSculpture.com — Home Page for Discount Hardware & Software

-

03-10-2011, 10:52 PM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Your spending far more and using motors with 4 times more torque than you need. A Gecko G540 package with 380 oz motors is perfectly adequate for the machine your building, $600 total.

You need to spend about a month reading everything you can to learn about what you're buying.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

03-10-2011, 11:49 PM #9

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Ok this would be my route to get the machine your looking for.! Basicly my machine but half as wide.

I'll break it down into component parts starting with the linear motion.

Rails ideally 20mm profiled sqr type Hi-win etc pricey but the best both in performance and reliabilty/longevity, If too pricey then supported round type DO NOT go with unsupported they are bad news. 16mm will be fine.

Linear drive. . . Erm this may start a debate!! . . Personaly at this length I'd go for Ballscrews.!

At 48" your on the edge of going with rack n pinion but I can tell you from experience that 20mm ballscrews this length work fine because I have them on my machine, 25mm more than enough.(12 or 16mm on Z axis) For the type of use you plan a pitch of 10mm will be a good trade between speed and resolution. (5mm for Z axis)

The bennifit of ballscrews esp when cutting aluminium is far worth the little extra they cost. They are far more efficent and accurate than just about anything else with massive mechanical advantage, both these factors translates into meaning you can use smaller motors which use smaller drives also they use smaller power supplys all this translates into slightly less money.

Combine ballscrews with profiled rail and you have a machine that will be super accurate with very good repeatabilty that will last for years even under harsh conditions. Buy from china and they will cost only slightly more than R&P, the other advantage if you buy from china is they will machine the ends for you for only a slight charge and supply the bearing blocks etc basicly making them a bolt on affair.! I have bought and fitted dozens of screws from china and can honestly say never had a bad screw or problem.

Motors & drives, Well I'm a Gecko fan and my personal choise would be 203v's drives matched with a large Nema 23 or small 34's. My machine use's 203v's with 3.5nm 34's for Y & Z axis with 8nm turning twin ballscrews for the X axis it almost exclusively cuts aluminium with 300in/min rapids.

It's very important with steppers that you match the power supply size to the motors, the specs on the motors will lead you to the correct size required but if you work on a rough guide of 20x the motors rated voltage this will give you a ball park figure.

The other option and again a very good option is the Gecko G540 this is a fanstatic piece of kit and for the price it takes some beating considering what you get, only draw back being it restricts you to 3.5A motors and 50V which basicly rules out all nema 34's and some of the larger 23's. But if moneys tight this is the best way by far IMO and if combined with ballscrews it will easily do what you need with 475oz/in motors. Basicly then all you would need is a power supply and your set to go.!

At 24" wide you will get away with 1 screw down the centre wider and I would consider twin screws for the X axis to prevent racking or twisting of the gantry.

Frame work.!! Well stronger the better so steel or Alu profile, steel works out very cheap and strong but needs skills and tools to build (welding drilling etc), profile is mostly bolt together but more costly. Again just IMO but stay away from using wood or MDF to me it as no place on a cnc machine other than to be cut.!!

Hope this helps and best advice iI can give is RESIST the urge buy untill you understand fully what you need, you'll only waste money if you buy in haste.

Cheers

Dean.

-

03-11-2011, 12:15 AM #10

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Also just spotted you mentioning micro stepping, if your chasing resolution then micro stepping is not the place to get it. past 10x micro stepping is pritty much point less for number of reasons, goto the gecko site and read about why.

The pitch of the screw is the best place more resolution smaller pitch, the price you pay is loss of speed. . . Resolution is always a trade off between speed.

My machine use's 5mm pitch screws but geared 1/2 this affectively gives me a 10mm pitch but with a loss of torque, when I need the extra resolution of the 5mm pitch I just change the pulley and work 1/1.

The attached pic should show you what can be achieved with a 10mm pitch in Alu, I very rarely need to go 1/1.

-

03-11-2011, 01:55 AM #11

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 253

hemsworthlad that Aztec calender is amazing, what size is it?

RobI'll get it finished sometime after I start it.....

-

03-11-2011, 06:55 AM #12

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Thanks in advance for your guy's responses,im finally getting a solid idea of what to do now

Hemsworthlad,

My god that Aztec thing was amazing!!!!!!!!!

I copied down everything you said in your post and am trying to make a parts list from it,would you have any links to suppliers or manufactures names.I mainly do all my shopping on ebay so im hoping i can find most of it on there. My jaw hit the floor when i typed in ball screw ,1 screw going for as much as 1800 bucks and another one was 10,000 dollars,for 1 screw!

Ger21,thank you for your post,the Parker compumotors are officially off the drawing board.

After reading Awerby's post ive decided to nix the Lumen lab kit and the Zen Toolworks kit on the grounds of no faith it its structural integrity and am focusing on the Fireball V90 cnc system now.Whats your guys take on it?

I have been scrutinizing this kit for some time now.3 Axis Nema 23 stepper motor 425oz.in CNC Router / Mill - eBay (item 200578892226 end time Mar-22-11 18:21:01 PDT)

basically cause everything's there,and i believe its a matched system,the only thing being is Im very hesitant about buying from china,last time i bought from china a dude ripped me for 25 bucks for some Leds when i was trying to build a Diy LCD projector.(i have add/ADHD..in HD lol so i have alot of hobbies) id really appreciate everyone's take on the kit mentioned above (the one from china) at 200+98 shipping its more in my price range for motors/controller/power supply,another concern i have with it is will i need drivers for it? if so what kind are best.i want to use gekos cause everyone says the are the best but they are just sooooo expensive!,im just a dude that only gets paid 1 every 2 weeks so you see my dilemma,i gotta be frugal.,I mean if i could find some used Gekos for 75-100 each,yeah then id go for it, by right now my eye is drawn to anything below $75.

i have this 20mm linear ball bearing xyz cnc shaft set with blocks - eBay (item 330537269030 end time Mar-10-11 20:12:58 PST) selected as my "linear rig" cause again i believe its a complete kit and what i gather is you just build it around your "table" again if ya'll could take a look and give me some feed back id very much appreciate it.(as a rule of thumb should all linear rod/shafts be supported?)

Here is another kit ive been eyeing alot lately as another possible basis for my design,just tossing it out there real quick for some feedback.KIT Desktop CNC Machine Engraving Milling Router - eBay (item 310274442484 end time Mar-26-11 02:46:28 PDT)

and another,

22x30" CNC mill router kits industrial grade engraver - eBay (item 260696689900 end time Mar-21-11 23:36:38 PDT)

and again another,im sorry (please forgive me if i seem annoying or whatnot,its not intentional)

4 X 4 CNC PLASMA TABLE DIY GANTRY KIT WITH Z-AXIS - eBay (item 150410281330 end time Mar-27-11 13:35:28 PDT)

Ive also been looking alot at things like this,i have to post another link cause i find it difficult to describe.Cnc PC Control Router Mill Linear Actuator for Z AXIS - eBay (item 320658154966 end time Mar-17-11 18:51:46 PDT)

basically a complete motorized axis with accuracy ,the one being displayed isfor the X asis,but i wonder if enough were gathered could a "system" be built around something like this? Just an oddball idea is all.

well thats all i have for now,im off to collect more PDF files,read more documentations,collect and stare and compare more pics of CNC systems.

again i appreciate all feedback and advice,and i thank you sincerely for it.

Keith.

-

03-11-2011, 07:27 AM #13

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1183

The V90 also has an MDF frame that some will say isn't

any good. But there are many hundreds of them out in

the world working as they should be. All machines will

have some limitations and the V90 works very well within

it's limits.

If you're at all interested in the V90, it'd be a good idea to

sign up on the support forum and look at the thousands

of pictures of what others have made with their machines.

Also ask any questions directly to people who own them...

Fireballcnc : FireBallCNC

If you need a machine that's larger or capable of heavier work than

a machine like the V90 can do then an all metal machine would be

the better choice....

John

-

03-11-2011, 11:43 AM #14

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

robe_UK: It's 150mm 9.5mm thick 6061-T6 Ali and done with a 6mm 90deg spot drill.!! the only bit I had that went to a point and was done as play test. The picture dont do it justice the detail in the flesh is amazing.

Kobra: I get all my ballscrews from Ebay from linearmotionbearings the guy is called Chai and very good to deal with. You will be looking around $450-500 for ballscrews for 3 axis with all the machining and end blocks. In uk I struggle to buy just 1 ballscrew with blocks etc for that money. He also does supported round type linear rail but I've never used it because i have a very cheap source of profiled rail here in uk.

Motors/drives.!! Well your in the land of the free and the best place to buy from your spoilt for choice.! Kelling, Ahren(cnc router parts) even direct from Gecko.

-

03-11-2011, 05:48 PM #15

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Imo, stay away from those Chinese drives. there are many threads here on their problems. And those 425oz motors are usually a poor match for any drive not capable of supplying 80V, due to their high inductance.

Again, the best performing drive for the money is the Gecko G540. Buy a kit with 380oz motors, which are perfectly matched to the drive, and a 48V power supply. get them from Home, or CNCRouterParts

This is the setup that 9 out of 10 new builds you see here are probably using.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

03-11-2011, 07:12 PM #16

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

Kobra:

The electronics are the heart of a good cnc machine and trying to do them on the cheap is a big mistake meny new to cnc make.

All that will happen is you'll be doing open heart surgery all the time and will still end up with an heart bypass.!. . . . Do your self a big favor and forget any thoughts of cheap chinese or DIY drives they can and most probably will give you a corenery episode.

Take Ger's, myself's and meny others advice go with the gecko's even if it means waiting a little longer untill you have the funds, it will be money well spent.

-

03-11-2011, 08:36 PM #17

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Hem

im going to check that out on the ballscrew and the seller,though the prices of it are shocking,(isnt it just acme thread wit ball bearings set it in the raceways?) if i cant get something affordable could i go with an Acme thread? i have a few sellers saved that sell between 2tpi and 8 tpi acme thread (im still learning about it im not sure if less is more on that particular subject) on ebay that are quite a bit cheaper.

I was wondering if you could possibly show me a example of profiled rail,post a pic or a link.

As for the choices in the land of the free,well there pretty nill,everyone ere wants a 75%-100% profit margin.and for a dude that makes less than 400 take home pay,well i got to be as cheap as i can,Thats why im looking into getting a kit from China,that is if i can find a seller from China/HK that has 100% feedback.

-

03-11-2011, 09:10 PM #18

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 624

No there's lots more to ballscrews than that but if your on a budget then acme thread will do.

If you cant afford ballscrews from china then forget profiled rails they are way out of your price range, just search for hi-win or thk.

If you buy drive motor kit from Ebay/china you WILL REGRET and waste money not save, listen to what folks are saying to you they are not just Fan BOYS it's experience talking.

-

03-11-2011, 09:15 PM #19

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Good afternoon guys

Ok im going to post some links to some linear setups first and id really appreciate your feedback on it guys.

linear rail 3 SBR16 sets + 3 ballscrews RM1605 type - eBay (item 250506978766 end time Mar-24-11 23:02:04 PDT)

a linear rig with 3 ball screws for 377+187......a few months saving but doable i think.

Mazak Quick Turn 10N Z-axis Ballscrew Part #51408400100 - eBay (item 350308335611 end time Mar-18-11 09:03:31 PDT)

a ball screw for 200..........i still dont know about that stuff.

and here are some chinese CNC kits ive been looking at,i was lookig at individual motors but ive changed my mind and want to get everything in one shot.

Cnc Mill 3 axis 86mm 30kg stepper motor PC Control Kit - eBay (item 320669283095 end time Apr-08-11 23:48:52 PDT)

no controller board in this one though.

Cnc Mill 3 Axis Kit NEMA 23 MICRO Step 3 Phase 360oz.in - eBay (item 320655668511 end time Mar-12-11 20:17:36 PST)

still no controller board in this one but alot of other stuff.

NEW 3 Axis CNC Controller Kit, w/ Vexta Stepper Motors - eBay (item 220751061790 end time Apr-06-11 15:28:15 PDT)

looking at this one really really hard.

3-Axis CNC Laser Stepping Motor Controller Driver - eBay (item 230413315451 end time Mar-11-11 12:54:44 PST)

a controller board selected for the kits above that do not have one included.

There are many other kits available,but the cheaper you go,the weaker the kit gets with its motors. which brings me to these next questions

What is the application and basis of holding torque?

What is a good baseline Holding torque 400ozin? 500oz in?

Can someone give me a bit of a definition on what 1/16,1/2/and 1/4 step and the like means?

What is Micro Stepping compared to Full Stepping or 1/4 stepping?

What is Backlash?

What is the importance and use of phases in your motor setup 2 phases,4phases,5 phases.

When using a kit that has individual Drivers,will they get there power from the controller board or is it a direct shot to the power supply?

How does Ballscrew compare with Acme thread/screw

Im just starting out so i think im going to have to avoid the AC stuff for now and just stick with a plain Jane 2-4 phase 24-48vDC 3.5-4amp kit.anything more that and i agree with ya'll im going to be blowing money down the drain fast.I feel like im getting closer to my goal,just need some more input,a few concepts still are hazy and undefined.

thank you all for your input and help,if i could email you a case of beer each i sure would.

Keith.

-

03-11-2011, 09:22 PM #20

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 132

Ok ,then please ignore the post i just made,lots of chinese kits in there..

Yes ball screw is completely out of my price range,(my GF would drop a solid gold brick if not beat me severely about the face if she knew i dropped 350-500 bucks on a single metal rod)

If anyone knows of any American kits (oddly enough i cant find very many if any American based sellers,though i live in Mississippi) or kits out of Canada,please please let me know,im going blind reading Ebay all night. my max price for kit is 350-400 bucks.

thanks

Keith.

Similar Threads

-

Nightmare with 10.04

By welderfabrod in forum LinuxCNC (formerly EMC2)Replies: 21Last Post: 02-26-2011, 08:18 PM -

Sandvik Nightmare!!

By JayB in forum MetalWork DiscussionReplies: 2Last Post: 08-27-2010, 01:08 PM -

IGES nightmare

By Med-Pac in forum Uncategorised CAM DiscussionReplies: 2Last Post: 12-14-2007, 06:58 AM -

plasma Cam nightmare

By evoacc in forum PlasmaCamReplies: 4Last Post: 06-27-2007, 02:37 PM -

I had a dream...

By datacop in forum CodingReplies: 1Last Post: 07-17-2006, 07:53 AM

Reply With Quote

Reply With Quote