I am upgrading my lathe to CNC, it's an Ebay special!

Here's a pic

The Mill attachment is pretty much useless as it's might as well be made from cheese, so I taking this off. I'm also building a better frame with a built in coolant system. Structurally the lathe is not bad, but the electrics leave a lot to be desired.

The is similar to the Grizzly G0602 lathe, just a little bigger with an 11 inch swing a 28 inch between centres. So I'm getting a lot of how to do the conversion from those threads, which I thank the authors for posting them.

I hope to order the steel for the new frame next week, but this week I am concentrating on pulling the lathe to pieces to check what's ok and what's not.

I am toying with one idea, which I am not sure how to do, so I'll pose the question here.

I want to make the spindle an axis, so I can turn a piece then mill it with a live tool on an auto tool turret. How can I do it?

I'm thinking a servo motor with the appropriate rpm and power, but I'm sure someone will say otherwise.

I'll post some more pics as I go.

Thread: Lathe conversion

Results 1 to 14 of 14

-

03-14-2011, 11:37 AM #1

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Lathe conversion

-

03-15-2011, 07:50 PM #2

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 0

Hello

You have a lot of plans. Do you have more than 7 days in a week?

Spindle axis: Would it be a good idea to do it with a dual drive? One with a normal motor for turning and one (detachable) with a steppermotor for milling.

Building a toolturret with the possibility of a live tool: Following threat is a good start. • turret bouwen(updat 2-2 nieuwe film draaitsnijden )

greetings

-

03-15-2011, 08:50 PM #3

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

-

03-17-2011, 07:04 PM #4

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

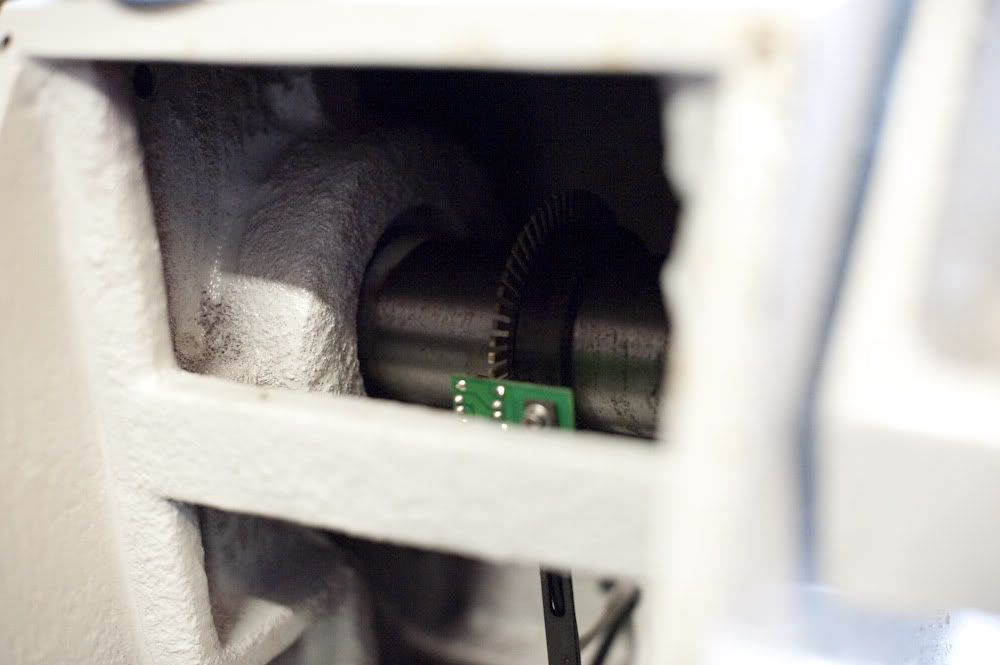

Given what I want this lathe to do and what I have learnt from my other thread http://www.cnczone.com/forums/genera...tor_lathe.html, I took the cover off the headstock today to see what is used to measure to spindle speed.

Sorry, it's about the best shot I could get.

You can see an encoder with slits cut into a disc and an optical switch.

This sends an output to the LED display, on the cover, which in turn shows the spindle speed.

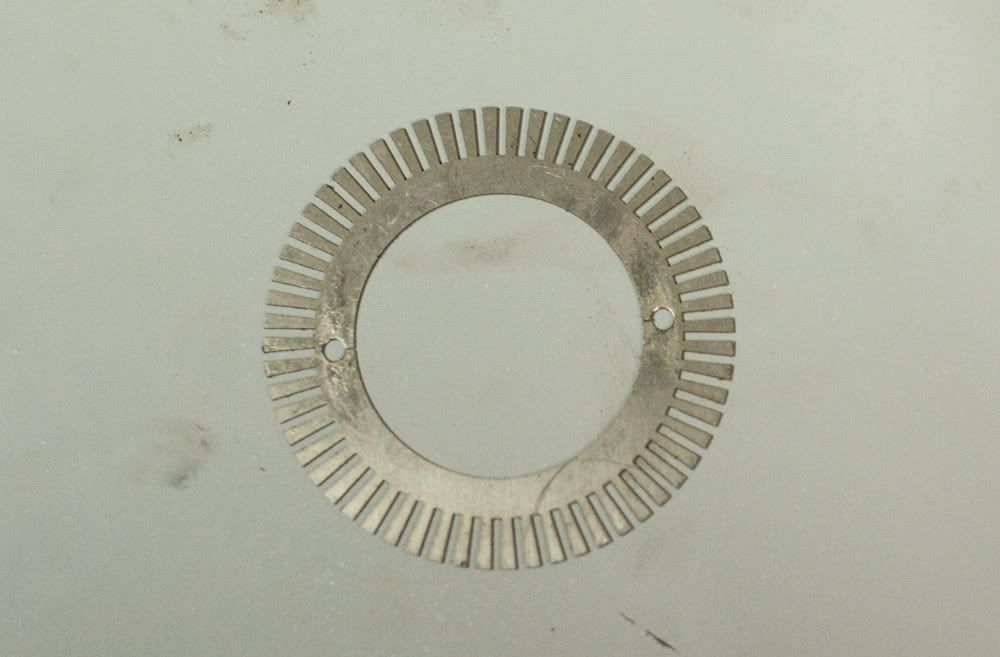

This is a similar disc to the one on the spindle.

I have two options the first is to use a single motor to provide both my lathe spindle & my C-axis, or second, use a separate servo motor in addition to the spindle motor.

I'll try the first option initially, and if it doesn't work I can still go for the second, what don't want to do is go for the second option only to fine I didn't need to, and the first option would have worked perfectly.

As, I don't think I'll be able to add three outputs to the encoder wheel on the spindle, there's only one at the moment. To get the indexing output I'm going to have to make a second encoder wheel, with only one single slit cut, and fit that to the spindle, to achieve the indexing output. Hopefully this should give me a working encoder on the spindle.

The Spindle motor is going to be a 2.2kW 240V AC induction 1500rpm 4 pole single phase motor, driven by a Mitsubishi E700 VFD. The E700 has sensorless vector control. If this combination works, great, if not I'll go with plan B and add a separate servo motor to provide the C-axis.

-

03-17-2011, 07:48 PM #5CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

03-17-2011, 08:58 PM #6

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

The E700 seems to be the best one I can find at the right price.

As per the motor this is where I found it ACP&D Limited - CW Series - Single Phase Induction Motors, and yes it is single phase.

My electricity supply is 240V single phase, do you recken same "kw" but three phase. If so I'll go with that, just single phase costs less.

But as always, you get what you pay for.

-

03-17-2011, 09:03 PM #7

The idea of using a VFD on 1 phase is that it converts to 3 phase to allow the advantages of using a 3 phase motor, you most certainly will run into issues trying to run a 1 phase motor on that VFD.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

03-17-2011, 09:42 PM #8

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Ok cool.

I had a look at the 3 phase version of the same motor and it's actually cheaper than the single phase, so much for single phase being cheaper.

-

03-18-2011, 08:57 PM #9

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Been looking at various servo & stepper drives, and came across Geckodrive.

I have no experience of them, it's just I can get them in the UK.

I was looking at the G540 4 axis step motor drive, as it's got an output for a VFD.

Anybody used them, are they good or bad?

On the Encoder front, I found these people www.ifm.com they have some encoders at a very reasonable price.

If the encoder in the lathe doesn't quite work out I'll give these a try.

They have an option for an encoder wheel, so I can place one on the lathes spindle and measure direct, just got make an appropriate bracket for it.

-

03-19-2011, 10:26 PM #10

Charter Controls import Geckodrive bits - Charter-controls

Just search for either Gecko, or the drive model number.

-

03-19-2011, 11:54 PM #11

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

-

03-20-2011, 10:59 AM #12

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 607

There is an entire section dedicated to Gecko drives. These are some of the most popular drives to use on hobby cnc machines, and I myself use some (not the G540 though).

Gecko Drives - CNCzone.com-The Largest Machinist Community on the net!

Look around a bit, and you will find several topics on that specific unit. Doing a search in the benchtop machine forum will also turn up several hits.

-

03-20-2011, 09:34 PM #13

As said, Gecko have their own forum on here, and are very popular.

I've just replaced the controls on my lathe with G251s, which is the same drive as what's used in the G540. They've still be used in anger, but they've performed well so far while setting everything up.

-

03-20-2011, 09:59 PM #14

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Thanks guys

I've been reading the Gecko section, and I think I'll go with a Gecko drive.

But looking at what I want my lathe to do, I'm going to have to go with servos.

So it looks like I'll be getting the G320x and a Pico systems universal controller.

Any other suggestions/recommendations for a controller would be nice

Similar Threads

-

C4 Lathe CNC Conversion

By compunerdy in forum Benchtop MachinesReplies: 14Last Post: 11-26-2012, 07:26 PM -

7 X 12 CNC Lathe conversion

By fragger6662000 in forum Mini LatheReplies: 2Last Post: 12-01-2009, 09:18 PM -

DIY Lathe Conversion?

By Hdale85 in forum DIY CNC Router Table MachinesReplies: 4Last Post: 09-28-2009, 07:43 AM -

Anyone done a C6 lathe conversion

By mcraig79 in forum Mini LatheReplies: 0Last Post: 11-13-2008, 11:38 PM -

PC 200 CNC Lathe Conversion

By ERL31 in forum Australia, New Zealand Club HouseReplies: 0Last Post: 06-15-2008, 08:56 AM

Reply With Quote

Reply With Quote