Well, I guess it's time for me to post about a problem I've been trying to solve for a week now. My Y axis isn't smooth during it's travel and it's leading to a rippled surface finish. I'm pretty sure it's related to the gib adjustment. I had no issues until my new machine worn in a little bit and I had to adjust the gib because the table was loose.

I've tried half a dozen times to adjust it and I get the same results every time. I loosen the gib screws up and then evenly tighten till I feel resistance. I check that the table moves smoothly and I also check for play by moving up/down/left/right. I adjust until there is no play and the table still feels relatively smooth. I then lock down the nuts.

The table will sound good and move well and then I'll start a job. It seems to start off well but quickly I start to hear that slight uh uh uh noise that tells me it's not moving smoothly like it should. It's much like a vibration related noise and it only happens with a load applied. If I try to adjust it loser I can feel play in the table and hear it during cutting. I've even taken it off the base a few times to clean/lube/etc and that hasn't helped.

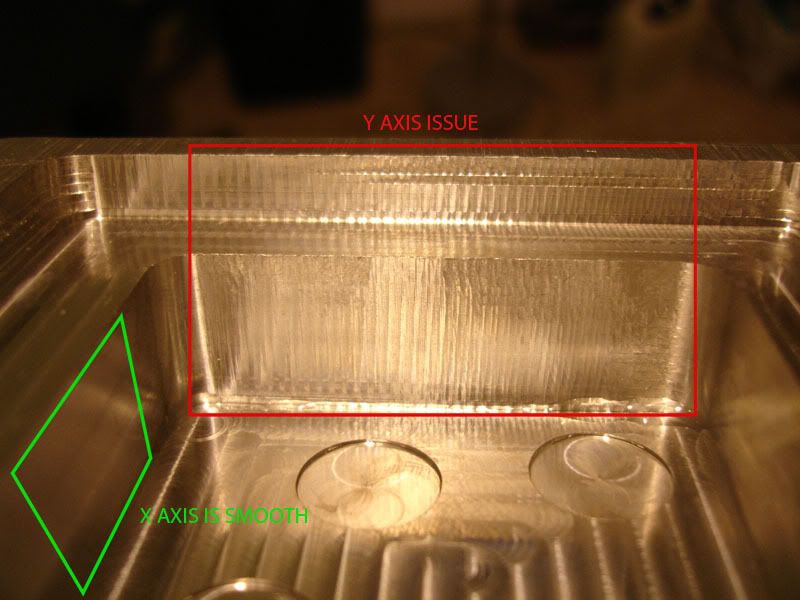

Here is a picture that shows what I'm taking about. You can barely feel them...but you can still feel them unlike the X axis which is nice and smooth.

Thread: Y Axis Gib Issue

Results 1 to 8 of 8

-

03-26-2011, 01:20 AM #1

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

Y Axis Gib Issue

-

03-26-2011, 04:30 AM #2

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

Just pulled off the stepper and moved the table and it feels smooth with no play...maybe it's not the gib. Not sure what it would be though.

-

03-26-2011, 11:54 AM #3

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 294

Backlash in the feedscrew/nut, particularly if you're climb milling?

Play in the coupling of stepper motor to feedscrew?

-

03-26-2011, 11:57 AM #4

Member

Member

- Join Date

- Jun 2007

- Posts

- 3757

Might be a bit of rubbish IN the stepper.

Don't pull it apart!! but disconnect mechanically and see if rotation feels consistent through each rotation.

Then turn the ball screw, while disconnected, and see if it is smooth. It might have a lumpy spot, caused by a recirculating ball hitting a tight spot.Super X3. 3600rpm. Sheridan 6"x24" Lathe + more. Three ways to fix things: The right way, the other way, and maybe your way, which is possibly a faster wrong way.

-

03-27-2011, 07:42 AM #5

Member

Member

- Join Date

- Jan 2007

- Posts

- 162

Not on a Taig

But the thing to check is the bearings on the lead screw. If the preload has slackened these can be loose, but they can also become damaged, and a dodgy ball in one of the bearings will give a rough feel to the movement. It may not be noticeable with the leadscrew attached to the table, but once you drop the leadscrew off, as one would do to adjust the leadscrew nut loading, you can easily feel any 'steppyness' in the bearing itself.

Nick has bearings in stock and they are now expensive.Lester Caine - G8HFL

http://medw.co.uk - Home of electronics for the Model Engineer

-

03-27-2011, 07:39 PM #6

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

I went through and tried/tested everything that was mentioned so far and it still seems to be happening. Only thing I noticed is that when I pulled the lead screw out of the nut that it isn't straight up and down. It slightly tappers upward as travels from the plate to the end.

Another thing I noticed is that the finish changes if I change the pulley rpm. Right now it's on 6700rpm but if I change it to 4200 or 10600 rpm the finish gets better. I'm wondering if it's vibration related.

-

03-28-2011, 02:06 AM #7

Member

Member

- Join Date

- Jun 2007

- Posts

- 3757

Looks like some sort of resonance.

At the same feed rates, try a cutter that has a different number of flutes/geometry.

Your spring pass may be a bit deep. It looks like you are using a single pass.Super X3. 3600rpm. Sheridan 6"x24" Lathe + more. Three ways to fix things: The right way, the other way, and maybe your way, which is possibly a faster wrong way.

-

03-28-2011, 04:14 AM #8

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

The piece in the picture was conventional cut with .0015" left over and then climb milled for the finish.

I went through everything again today that people mentioned and also readjusted my gibs. I'm going to do another one of those tomorrow with 4200rpm. I'll post another picture after it's done to show how it turns out.

Similar Threads

-

VA-50 Z axis issue

By DragonRider in forum Mori Seiki MillsReplies: 6Last Post: 01-14-2011, 04:04 AM -

Z Axis issue

By ranchak in forum Bridgeport / Hardinge MillsReplies: 0Last Post: 11-30-2010, 06:28 AM -

odd X Axis issue

By smittys800 in forum FadalReplies: 21Last Post: 08-04-2009, 06:42 PM -

Y-Axis issue

By studysession in forum Machines running Mach SoftwareReplies: 1Last Post: 12-28-2006, 09:11 PM

Reply With Quote

Reply With Quote