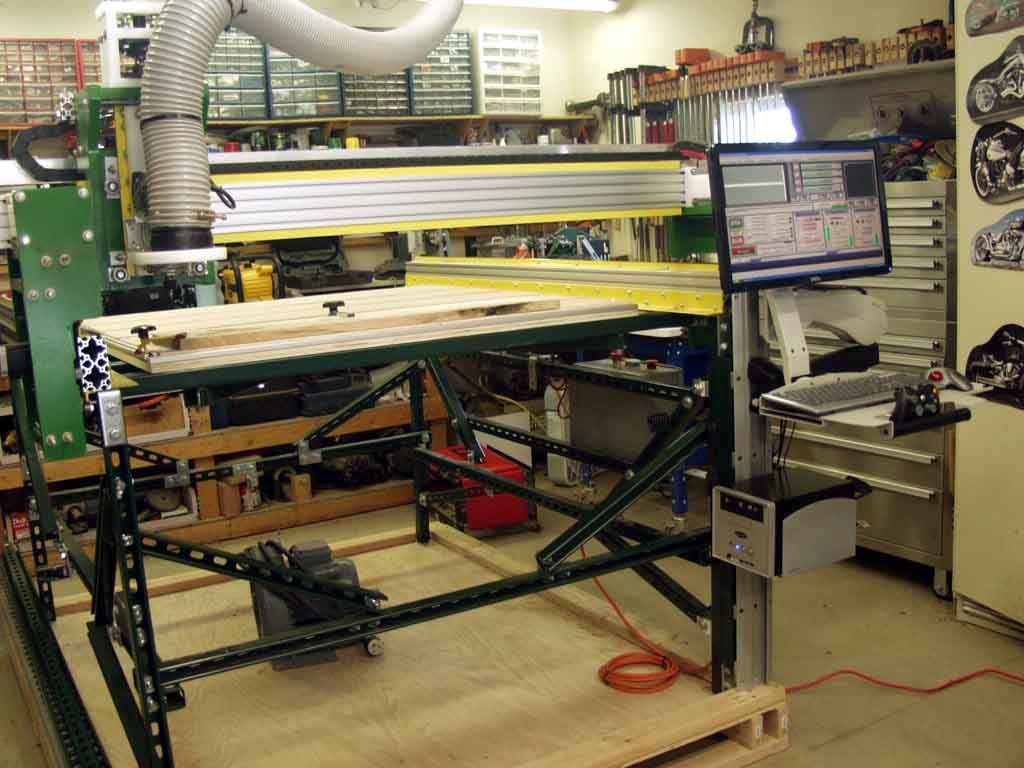

Hi Guys. I was reading Pat's large CastCNC thread here and thought I would post up some more CastCNC pictures. I built a pretty standard Joes Hybrid rack and pinion 4X4 machine last April/May 2010. I added vacuum clamping to it in September of 2010. This January I converted it over to a CastCNC V2 outfitted machine with the K2CNC 8" Linear Z axis. I also switched to a welded 11ga base (from unistrut) and switched to Vrail from angle iron. Here are some pictures of the conversion. I will try and post them in order but forgive me if some are out of sequence.

Mikie

First off - here is a walk around video of my CastCNC machine before the bed was installed and it is running the breakin test.

[nomedia="http://www.youtube.com/watch?v=_rBTJyOaeWY&hd=1"]YouTube - Walk around of my Joes Hybrid R&P CastCNC V2K2 CNC Router[/nomedia]

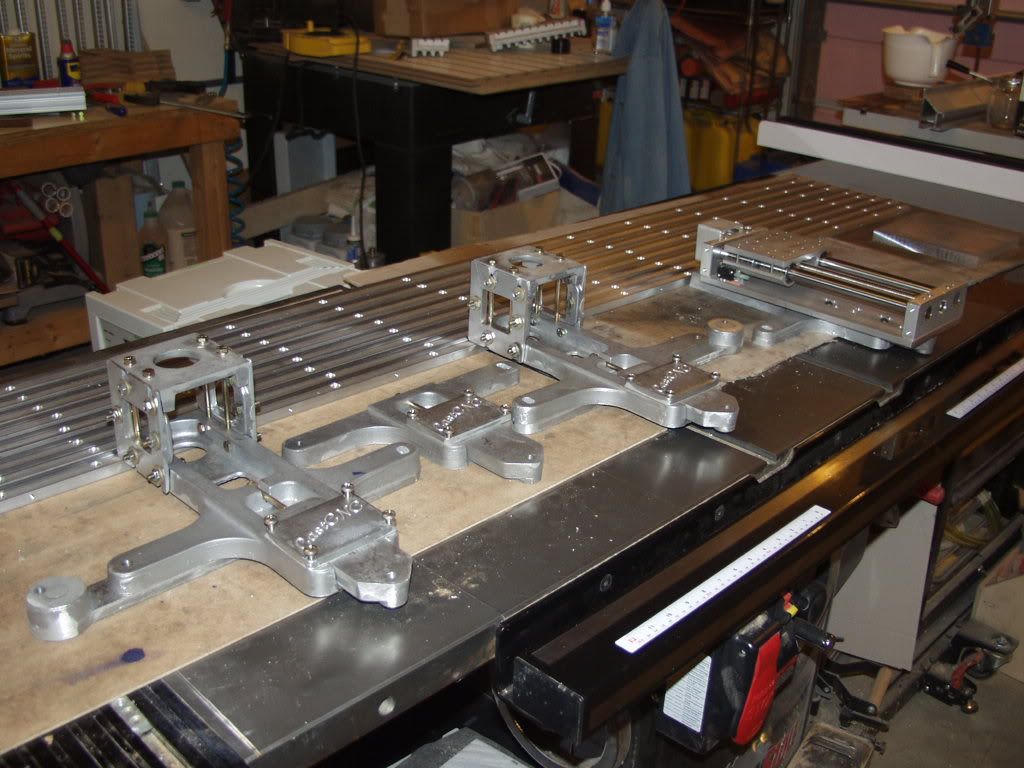

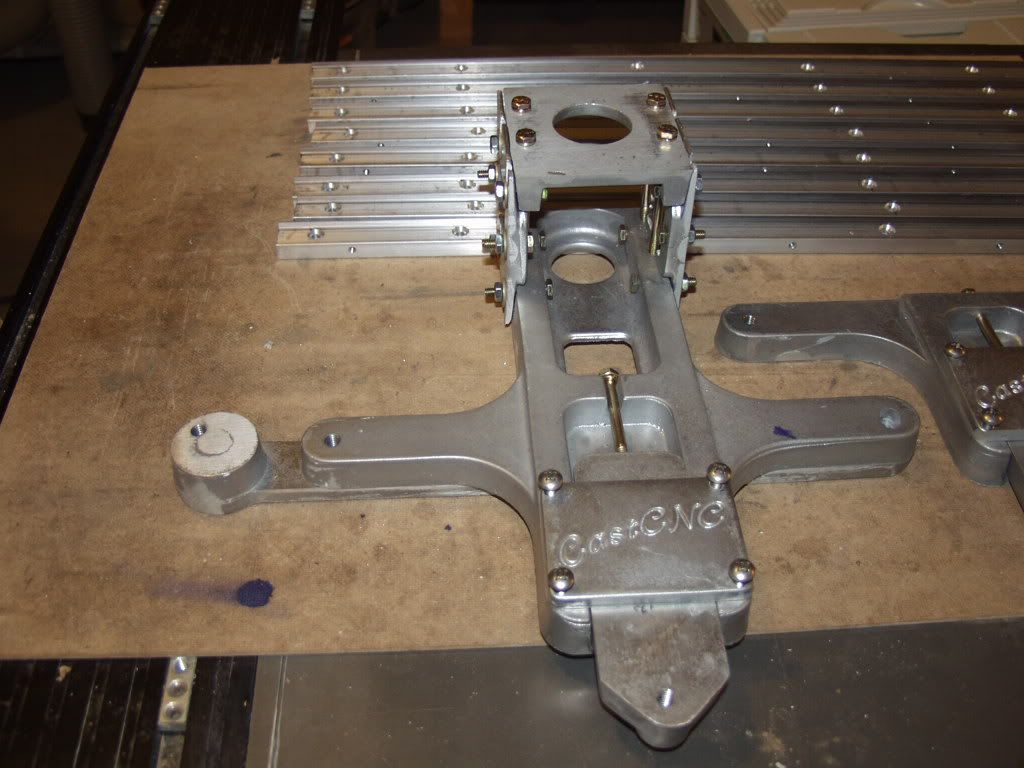

Here are a few of the parts you get from Harry at CastCNC. There are 23 of them. They come in almost perfect shape (Harry calls it rough cast but I digress) and require light cleanup and all the drilling and tapping.

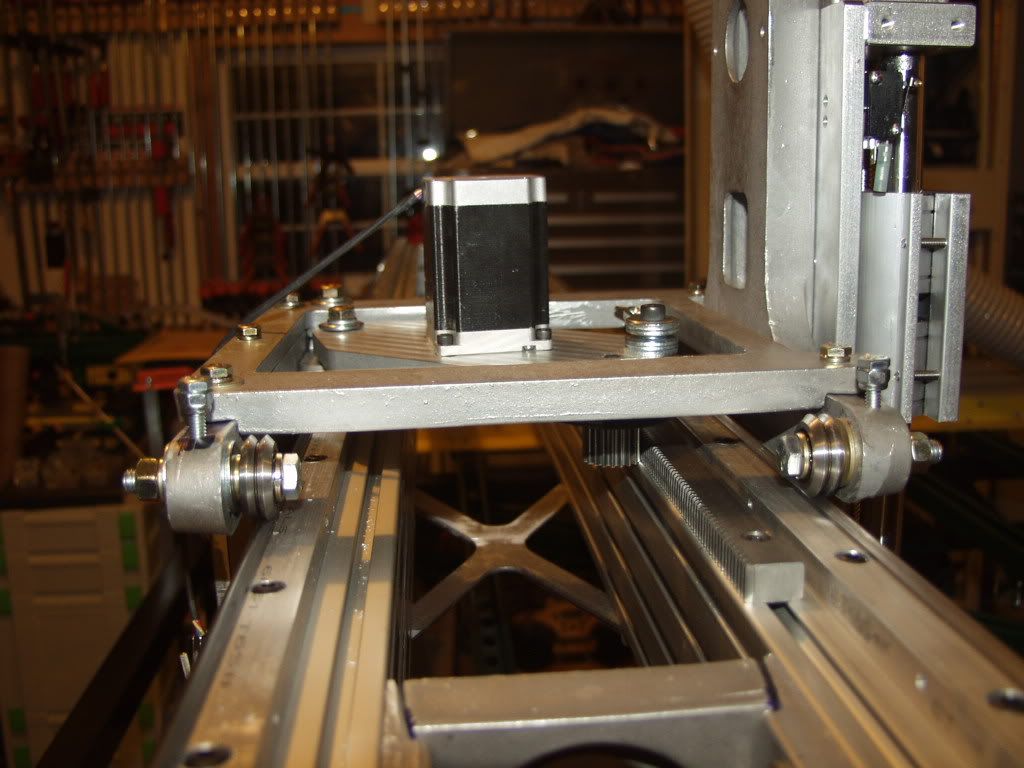

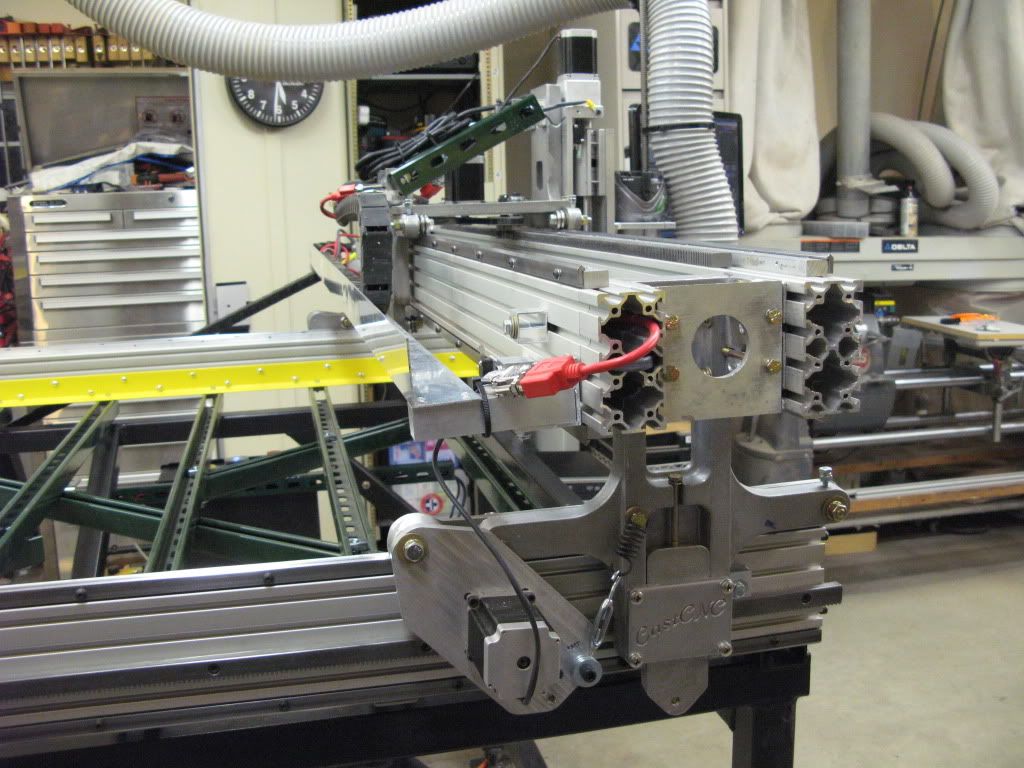

I will fast forward to the CastCNC parts machined and assembled and the Vrail installed on the aluminum bar stock. BTW - if anyone wants me to machine these parts for you for a fee ($400) let me know and that can be arranged.

A carriage comparison to an MDF/HDPE Y carriage and a CastCNC Y carriage

My new welded base

Base painted and Y rails installed

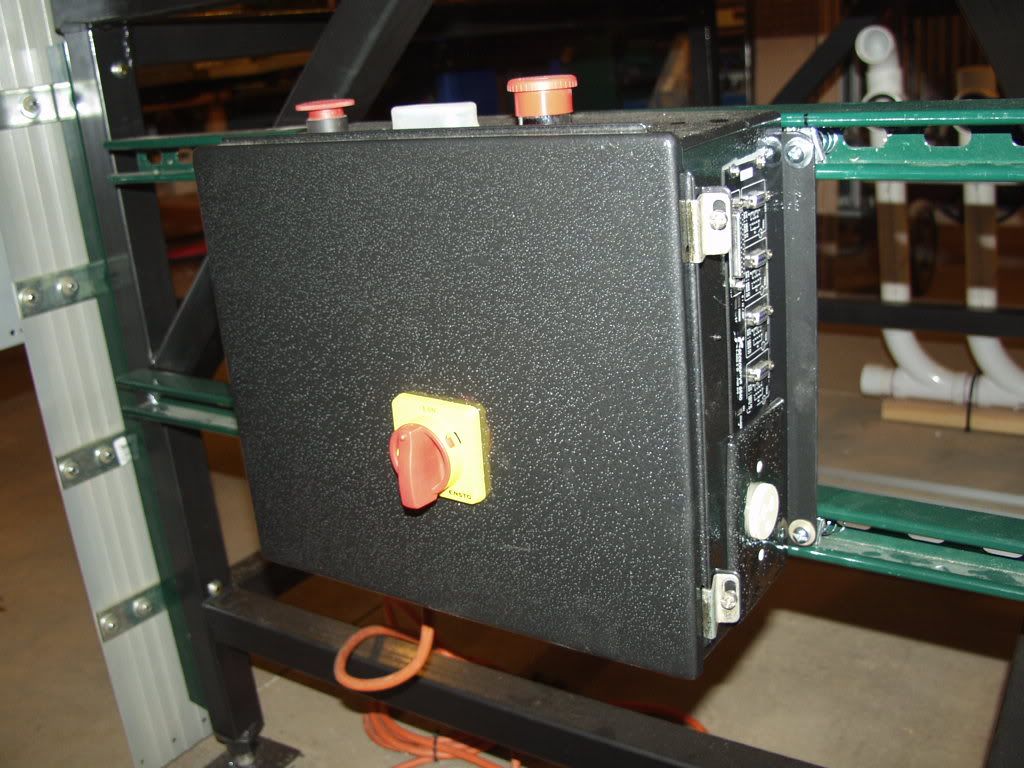

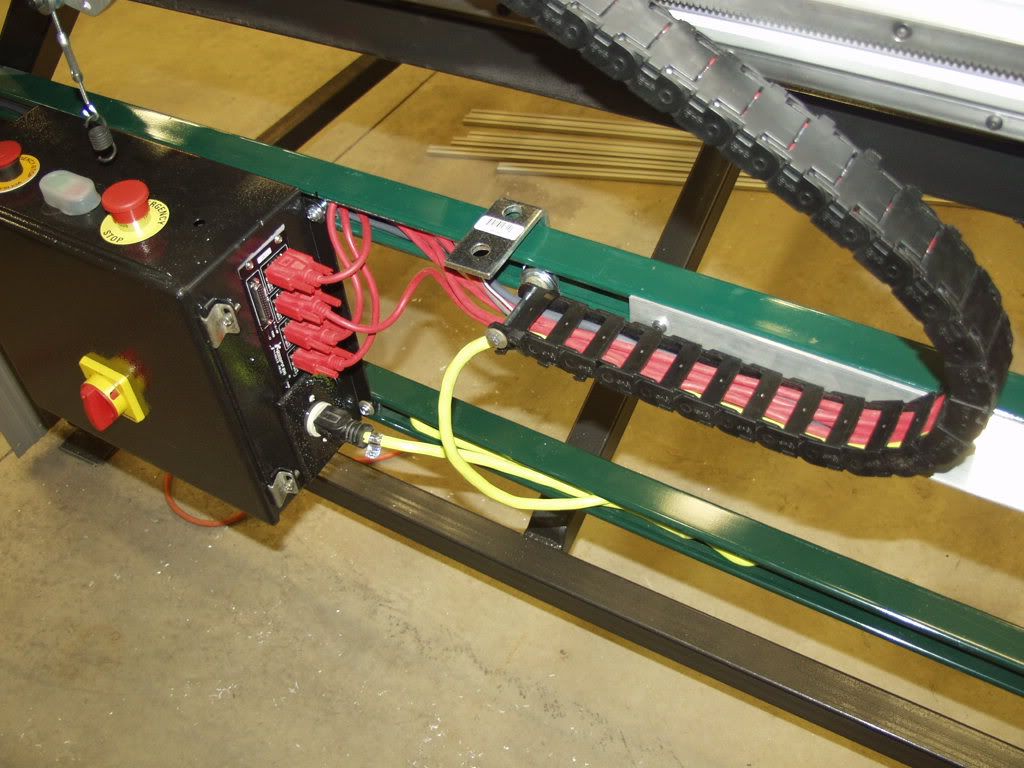

My controller box - G540 equipped with motor contactor, two estops (one for contactor coil and one for disable mode of G540), through hole disconnect, inputs and output accessability on outside, and relay setup for mach control or router.

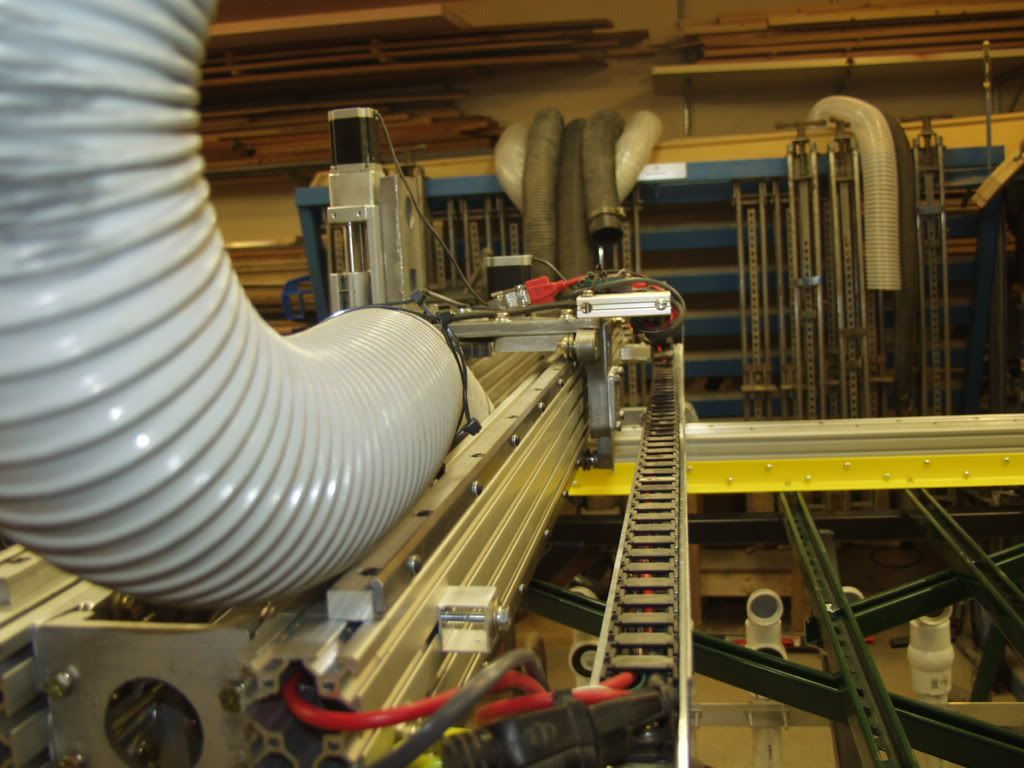

Getting the PC mounted, the X gantry installed with X/Z carriage, dust hose, and echain and wiring installed, and vacuum pump plenum and pump in place

Bed and 8020 T Track installed (everything bolted through the bed)

My original machine - My first machine build ever was teh Joes 4X4 Hybrid Rack and Pinion - Plans ordered April 9th and cutting May 20th.

Video of vacuum pump working

Results 1 to 5 of 5

-

03-30-2011, 08:53 AM #1

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

BloomingtonMikie's CastCNC machine (pic heavy)

-

03-30-2011, 09:03 AM #2

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Harrys castcnc site is CastCNC - Home

Joes 4X4 hybrid site is Joe's Hybrid 4x4 CNC Router

Everyone always asks about cost. Rough breakdown below.

The original build I had about $3.6K into with the component outfitted G540 controller box I made and the Regen blower vac pump from ebay.

I added about $2100 with the latest upgrades I made.

$500 base (11ga steel and welding work)

$500 Vrail and alum bar

$590 Cast parts for Joes Hybrid forum member/builder ($690 for non member as it includes the $100 access to Joes forum and his plans)

$400 K2 8" Z with .2 screw upgrade

$100 extra length of 72" 8020 extrusion

Recouped $750 from the sale of my MDF carriages, HDPE, angle iron, and unistrut base from my original build.

-

03-30-2011, 09:38 AM #3

Banned

Banned

- Join Date

- May 2008

- Posts

- 667

WOW, what a nice machine you have.

Would like to see more video of it, and when it's doing some work

Can you elaborate a bit about your vacuum system.

Really interesting.

Jeff

-

03-30-2011, 04:53 PM #4

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Wanted to Highlight Mikies offer of finishing the casting kit to folks. At $400 it is a great deal for anyone who is uncomfortable with doing this part on their own or simply doesnt have or want to spend the time. It is a good ten hours of work in cleaning up the parts, laying out and tapping the holes, then bolting everything up and test fitting it.

Mikie is a real craftsman and a great guy to boot which is why I made the arrangement with him to provide this service. I will be sending him a set of castings so that he can have at least one on hand so you never know, might be able to pick up a set with no lead time at all. Send me a note if interested the the email on the site and mention you want the work done by Mikie.

Regards,

Harrywww.castcnc.com The aluminum casting kit for Joes 4 x 4 Hybrid

-

04-01-2011, 09:35 AM #5

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Jeff. The Regn blower is from FPZ - Effepiezta from Italy. It had 2" NPT ports on it so I used 2" PVC to duct it up. I ordered a FPZ 2" relief valve and have it set to open at 6.5" Hg. It then goes into a Solberg canister filter that is also 2" NPT. From there I have my PVC manifold I made. It has a stack for the 4" Winters brand fluid filled vacuum gauge and then there are five 90degree long Yes that each go to a 2" ball valves purchased from Menards. With this new base and table I will install a sixth valve in the front that will just vent to atmosphere. The other five will get routed to zones I will cut into my MDF bed on my machine.

Here is a video showing it worked on my old setup at 5.2" Hg.

Here are some pictures from the previous unistrut base install.

Pump and relief valve

Pump 1 and 2

Manifold

Whole system

Grid

Work on lightweight MDF or LDF for cut throughs

Video showing it hold work through the LDF.

Similar Threads

-

CastCNC v2

By CastCNC in forum Joes CNC Model 2006Replies: 0Last Post: 03-09-2011, 07:46 AM -

Heavy 2X4 Router

By gd.marsh in forum DIY CNC Router Table MachinesReplies: 80Last Post: 11-18-2010, 01:35 AM -

CastCNC - Aluminum Top Out kit for Joes 4x4 Hybrid

By CastCNC in forum News AnnouncementsReplies: 54Last Post: 08-12-2010, 03:31 PM -

Heavy is good???

By zaebis in forum Syil ProductsReplies: 4Last Post: 05-28-2009, 01:17 PM -

Why is a heavy iron base vital for a good machine?

By Com in forum Mechanical Calculations/Engineering DesignReplies: 26Last Post: 11-29-2005, 04:41 PM

Reply With Quote

Reply With Quote