My Z Axis makes a nasty grinding sound when it rapids in the down direction..

I suspect that this might be the fact that the portion of the drive train that goes through the thrust washers, needle bearings, and main bearing block is threaded instead of smooth drill rod..

If I were to cut the screw back, and then use a coupler and a section of 1/2" drill rod, the extra coupling dimension would require that I rebuild the entire Z carriage, and I would also lose an inch or so of Z travel..

So what I'm wondering, is if there are suppliers of 1/2"-10 TPI 5 start screws out there that can provide the screw with the first two and a half or three inches of the screw 'un-machined'...

That way, I can just replace the screw as is, with the un-machined part traveling through the shaft nuts, thrust washers, needle bearings, and bearing block into my helical coupler..

The only other way I can think of solving this problem without completely rebuilding the Z carriage would be if there is some sort of small diameter coupling that can be used to couple the screw I have to some 1/2" drill Rod..

Or, maybe you guys have some better ideas?

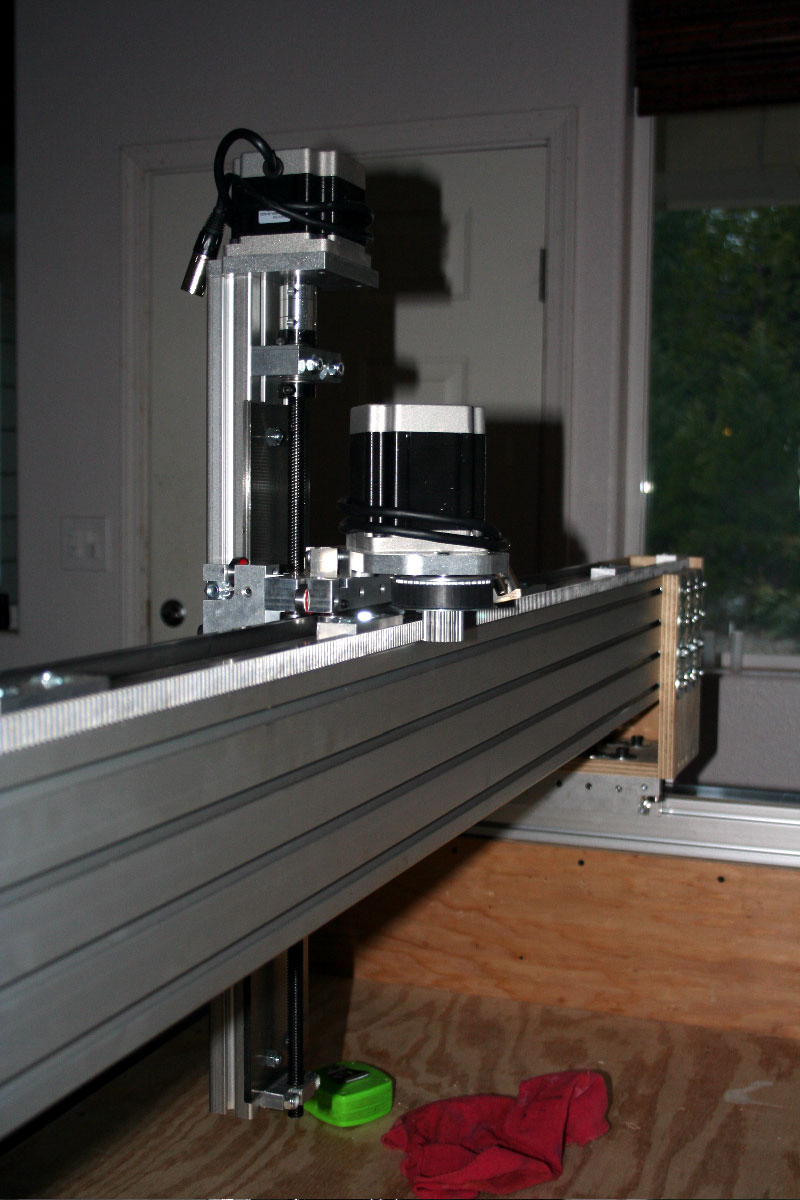

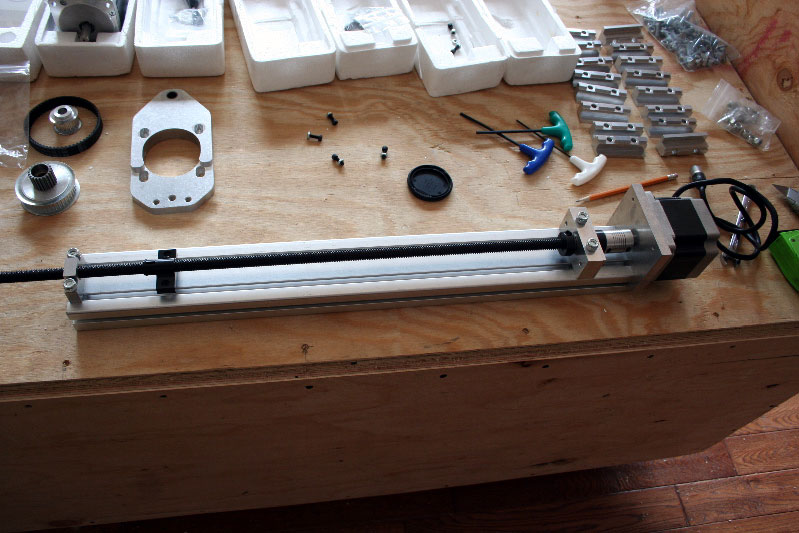

Here's a picture or two of how it's currently configured... (I'm going to post a copy of this question in my build thread too)..

Thanks,

Mark

Thread: Custom ACME Screw needed

Results 1 to 20 of 24

-

07-04-2011, 02:11 AM #1

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Custom ACME Screw needed

-

07-04-2011, 03:20 AM #2

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Would the CNCRouterPart.com "shaft adapter" work for you? You'd lose a little travel but not as much as you would if you used drill rod.

-

07-04-2011, 03:23 AM #3

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Another thought. My router made terrible grinding sounds if I moved faster than 15"/min until I lubricated my lead screws. Now no problems.

Have you lubed your lead screws?

-

07-04-2011, 03:52 AM #4

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Maybe.. I sent Ahren an e-mail for info on it a little while ago.. His website says almost nothing in as far as what it is intended to do, sizes, etc.....

So maybe you can answer my questions..

Is the smooth shaft on that thing 1/2"?

Is it designed to accept a 1/2" screw?

What is the overall OD and length of the coupling portion?

How long is the shaft?

Also, how come the shaft in the second picture looks so much longer than in the first? I was under the impression (from his website) that it was machined into the coupling... IOW, the shaft is not adjustable or replaceable..

-

07-04-2011, 03:54 AM #5

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

-

07-04-2011, 04:18 AM #6

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

you could probably turn it down and sleeve it with a piece of drill rod hollowed out; I'm sure a decent machine shop could do it...

-

07-04-2011, 04:31 AM #7

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Are the shaft collars I have installed necessary?

I'm thinking that if I used that adapter from CNC RP, and then eliminated the top shaft collar by butting the helical coupling right up against the thrust washer on the top side, and then eliminated the bottom shaft collar and butted that adapter coupling right up against the thrust washer on the bottom side, that eliminating the shaft collars might buy me back enough real estate to make it work..

I have about 1/2" (maybe a little less) on the far end of the screw I can steal if I need to also, but that will require sliding the 4" CRS down.. which I'd rather not do if I don't have to, because it would be a bit of a PITA...

-

07-04-2011, 04:46 AM #8

I have one in my hand...

it accepts a .5 screw, the shaft is .5 dia and 2" long.

OAL is 3.5"

OD coupler section is 1.35"

I'm not sure if Ahren sells other versions.

-

07-04-2011, 05:06 AM #9

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Excellent! thanks for the info..

My existing collars are 7/16" each, and I have about a 1/4" on top of the helical... So assuming I can use about 3/16" of that, I still need to come up with another 7/16".. Which I probably have on the other end, but I want to avoid that...

I might be able to grind a sixteenth off of each end of the helical and off of the one end of the adapter...

And I could take an angel grinder and carve out a little cup in the middlle of the 4" CRS, although that might look a little butchered...

OTOH, if I went ahead an moved the CRS all the way down on the other end, I'd actually gain about a 1/2" of Z travel from the process...

I just need to verify that I can 86 the existing shaft collars... I can't see why they'd be needed with a coupling on each side though....

-

07-04-2011, 05:12 AM #10

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 409

My Z does the same sort of noise.. it was just needing a bit of lube, I use white lithum grease and I have to do it regularly. I have plastic leadnuts and I think thats the issue.

Try the lube before rebuilding, even some light weight oil should allow you to see if its the nut needing lube or something else.

-

07-04-2011, 05:18 AM #11

I'm pretty sure Ahren uses 1 SC and one coupler on his FLA100 design. The shaft on the coupler goes through the bearing block and the SC goes over the shaft. That is probably why it is 2" long.

-

07-04-2011, 05:51 AM #12

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Drools,

Where did you find that image?

Ahren really needs to add more stuff like that to his site...

He'd probably have to spend a lot less time answering questions, and then people like me would build it right the first time... Or maybe I did..

I should start putting together a FAQ of all the 'gotchas' I ran into the hard way in this build... A tips and tricks page would have made life a lot easier for me throughout the process had one existed...

Thanks,

Mark

-

07-04-2011, 05:56 AM #13

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Mine is a plastic leadnut too..

Truthfully, that's the area where the sound seems to come from... Maybe that's why it only does it in the down direction... Going 'up' it sounds smooth as silk..

I have some lithium grease.. I'll have to wait till morning to try it though as I have cinder blocks stacked all over the top of the sacrifice board holding it down while the glue cures...

-

07-04-2011, 09:09 AM #14

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

I use pneumatic tool oil to lubricate my screws as recommended by Ger21. Tried dry lubricants that worked but just not as well. There was a discussion of this on posts #32-38 in my build log. http://www.cnczone.com/forums/diy-cn..._router-3.html

-

07-04-2011, 09:20 AM #15

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

I happen to have one because I intend to incorporate it into the rebuild of my machine that I'm sure will be required as my delrin nuts wear.

The measurements are:

The smooth shaft is 1/2"

The other side accepts a 1/2" acme lead screw

The overall OD of the coupling portion is 1.33" and the length of the coupling portion is 1.5"

The shaft is 2" long.

Both pictures are from Arhen's web site. The left picture is the coupler. The right picture is the coupling arrangement with 1/2" drill rod. Sorry about the confusion. You're right the shaft is not removeable from the coupling and appears to be machined from one piece.

-

07-04-2011, 09:29 AM #16

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

I really like how you are mounting your Z axis so that the 8020 extrusion moves up and down. I changed the design of my router mid build to do just that. Doing so reduced some of my useable travel that I was able to regain by shifting the CRS down. It really wasn't hard to do as I've described on post #56 of my build. http://www.cnczone.com/forums/diy-cn..._router-5.html

I do think that you'll find that your problem will go away when you lubricate your leadscrews and thrust bearings. Good luck and please post how things work for you.

Don

-

07-04-2011, 11:35 AM #17

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 149

A couple shots of WD40 on the screw just above and below the leadnut does the job for me.

I would not remove any of the shaft collars. They support the screw and keep it in place, bearing the full load of your axis and spindle, keeping the weight and stress from the coupler and motor.

I had visible backlash on the helical coupler, so I went back to the good old spider couplings.

-

07-04-2011, 05:32 PM #18Well if you download and install the free SolidWords 2011 you will be able to look at the free plans Ahren has available on his website. The pic I posted was just a screen shot taken while viewing the part.Drools,

Where did you find that image?

-

07-04-2011, 09:53 PM #19

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Well, I lubed it with white grease and that got rid of about 70% of the 'volume' of the noise.. but it still does it..

There's only two possibilities left.. One is the issue with the threads interacting with the thrust washer and needle bearings.. or the other is that the rod is bent.. Which I know it is.. came that way from McMaster Carr..

I think I'll just live with lubing the thing until I rebuild the table onto the steel base, and then I'll redo the Z carriage with the solid shaft adapter, a new screw, and a new lead nut... If it's not too expensive, I may even opt to have the screw machined...

At least it doesn't make my skin crawl anymore.. LOL

-

07-04-2011, 09:57 PM #20

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

It's the thrust washers/bearings/screw problem... I just squirted some lube in there on both sides of the bearing block...

Quiet as can be now... All grinding gone...

So I'll just keep lubing it until I do the rebuild..

Thanks guys...

:cheers:

Similar Threads

-

Acme screw as a R&P?

By Sil_x in forum Linear and Rotary MotionReplies: 18Last Post: 02-28-2011, 11:23 PM -

What Acme screw do I need....

By dbtoutfit in forum Mechanical Calculations/Engineering DesignReplies: 3Last Post: 01-29-2011, 06:57 AM -

acme or ball screw

By smarbaga in forum Mechanical Calculations/Engineering DesignReplies: 12Last Post: 06-11-2010, 04:46 AM -

what bearing fit with acme screw 1/2 -10(for cheap ball screw)

By apex in forum Linear and Rotary MotionReplies: 4Last Post: 07-27-2007, 05:15 PM -

acme screw to ball screw question

By Billw in forum DIY CNC Router Table MachinesReplies: 9Last Post: 07-18-2005, 06:10 AM

Reply With Quote

Reply With Quote