Hi folks,

I've now exhausted the questions I could think of asking Taney at Quick CNC about the K6100a, and have essentially decided to buy one with the 1.5kw spindle and vacuum bed.

So, here in starts a thread about the experience of getting it from China to just south of Christchurch in New Zealand.

I do have one question for the room though, as it were:

What else do I need to be thinking about?

I'll be buying a dust collection unit for it locally, and I'm looking at bits / collets already.

Anything else I should be thinking about?

Cheers, Chris H.

Thread: Quick CNC K6100a for a kiwi...

Results 1 to 20 of 100

-

07-28-2011, 07:07 AM #1

Quick CNC K6100a for a kiwi...

-

07-28-2011, 09:21 AM #2

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Chris, Congratulations. The K6100A is an excellent machine.

I would suggest you request the ER20 collet spindle ( if you have not already done so ).

Other than that you could work out a system to ensure the water bucket cannot be accidently tipped over. Maybe a stand with wheels if you need portability - this will also give you a better working height if you are tall.

Here is my setup -

The water bucket and fountain pump -

How the machine will arrive -

What about setting up your dust hose -

You may also need a 15 Amp power source.

Rocket.

-

07-28-2011, 09:38 AM #3

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

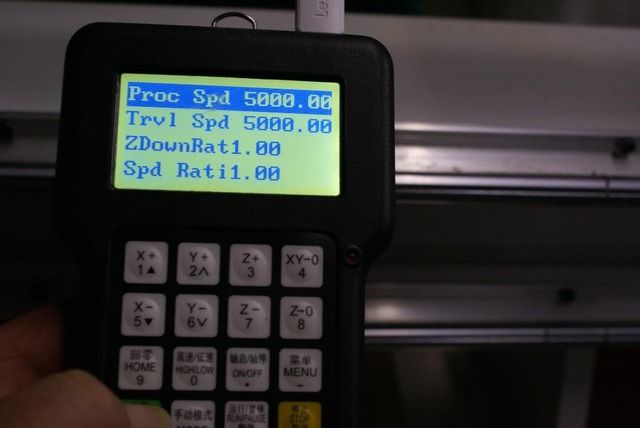

Chris, I normally run the machine at about 5,000mm minute for process and travelling speed, but you can run it faster if you want. I probably would not go faster than 8,000mm minute.

Our K6100 came with ER11A Collets. The first set of Collets i bought for it were ER11 - but they would not fit into the collet nut, so i bought another set and also a couple of ER11 collet nuts from a Hong Kong ebay seller which solved that problem. From memory the ER11 collets only go up to 6mm. That is why i think the ER20 collets would be better. Here is one of my sets -

Hope that helps.

Rocket.

-

07-28-2011, 10:21 AM #4

Hi Rocket....

I had wondered about the ER-20 vs ER-11. Is your ER-20 on a 1.5kw spindle?

I've only got 20A total available until at least June next year when we are planning to replace the switchboard. That makes me mindful of the power requirements given I'm already right on my budget running vacuum + dust extraction + router.

I know that each component wont pull it's rated power but I can see me popping the breaker for the shed if I push my luck too far.

A trolley sounds like a good idea, I'll wait and see how that goes.. I'm 5'8" so I'm 4" closer to the table than you so it might not be so much an issue. :-)

Hmmm, I've looked at your pics in the other thread a couple of time and never noticed your cooling water is a little green.... What are you using? antifreeze?

Cheers, Me.

-

07-28-2011, 10:35 AM #5

Arrr, our posts crossed in cyberspace...

So you've not got the ER-20 then anyway, ignore that question. :-)

ER11 vs ER11a,,. There's a gotcha, I didn't realise that the nut was the difference, off to Google I go!

I assume you're using the F read setting to set the feed speeds off your G code, and just the rapids wind up being 5m/m?

As an aside, I've seen a few moans about the DSP controller on the forums, but from the manual I found it seems like a really good solution and it removes the need to have a PC churning along beside the machine. Only down side I can see is no MDI and Sxxxx codes are not supported, which are not show stoppers at all.

Cheers, Me.

-

07-29-2011, 03:02 AM #6

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Hi Chris,

Yeah I use radiator coolant in my loop as well. I have my pump in a fairly sealed 5L bucket with lid that I bought from bunnings. The thing could tip on its side and very little coolant would get out. Like Rocket I have my machine on a trolley. I cut a ply wood base for it and the bucket goes in there underneath the machine so it is all contained.

-

07-30-2011, 12:10 PM #7

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Also just to reiterate what Rocket said. The ER11 nut that I bought from CTC tools says it's a ER11-A and works great for me. As you can see from Rockets photo some of the collets that come with the machine don't feature the ring found in most. The nut that comes with the machine also does not feature the eccentric ring of the ER system which is why you need to replace it.

-

07-31-2011, 02:50 AM #8

Progress on the process.

Thanks for those bits Marty & Rocket.. Bookmarked CTC tools and will order a collet set and nuts from them when I get the order away to Taney.

I'm just doing a last minute mental tally up of the options I looked at before committing money to this on Monday/Tuesday and I think I've made a good decision for what I want to do.

As the machines were difference sizes I've got a big of MDF in the garage with the table sizes drawn on it full sized and notes written in the boxes. A handy visual tool as this is a pretty big purchase for me in the scheme of things.

For me the things that sealed the deal:

- Vacuum / Tslot table even though I might have issues with power supply for a while.

- For my needs it's a good compromise between cutting area, physical size and power requirements.

- Feedback on the forums about Taney and Quick-cnc in general.

- Very positive impression of Taney and his attitude. I contacted four other Chinese manufacturers during this process and he stood out head and shoulders above the others on how well he answered my queries.

- DSP Controller for my needs seems like a very good fit.

Note that I didn't list Price there. The K6100a was actually the second most expensive option I looked at. Nothing else to say on that really.

Extra's I'm buying to have to stump up for as part of the process:

- Dust collection. Purchasing from a local company, 750w dual-bag thingy. I see no point in importing that.

- Port / customs fees. Already got written quotes for that part and confirmed forwarders and shipping details. (There is no duty in New Zealand for Chinese imports due to a free trade agreement between the two countries.)

- Collets / nuts per the other messages

- Vcarve Pro. Currently using Cut2D and I'm thinking I'll want Vcarve about 5 minutes after powering the machine on. :-)

Issues:

- I'm going to pick up the crate from the port myself, will have to borrow a bigger trailer or rent a truck. :-)

- Space. Need to clean out the garage!

- Power. I do believe I'm going to run into trouble with blowing fuses, but I have a plan 'B' and I can run an extension lead with RCD on it from the house to run the vacuum until we replace our dodgy old switchboard next year. (3 phase in the garage? I think so! )

)

Onwards and upwards for early next week, when the 1 month starts for the box to arrive. :-)

-

08-01-2011, 02:01 PM #9

Quick update...

It's a done thing, ordered the machine and paid for it this afternoon.

Provided a copy of the invoice to the local office for the freight forwarders and sorted out registering as an importer to pay GST (local sales tax) when the machine arrives.

Quoted time to get the machine to the port at Qingdao is 15 days.

That might actually be 15 working days, so 3 weeks, didn't ask but it's going to take me that long to tidy up the garage where it's going!!

From there it's into a consolidated container and on to Shanghai. Then Shanghai to Lyttleton which will take 16-18 days. I imagine it'll get tied up in the customs/inspection process for a couple of days and then I can pick it up.

The worst part of any remote purchase! The waiting for it to turn up... :-)

Cheers, Me.

-

08-02-2011, 01:30 AM #10

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Well done Kiwi, Looks like you have got it covered.

The following photo will give you an idea of the crate size -

Just a quick note about those prices you mentioned. In another thread relating to a cheaper machine a certain poster put up a photo of his control box. It did look rather cheap and nasty. Here is a photo of the control box for the Quick CNC K6100A -

That is quality of manufacture . Well worth the few extra bucks!

Rocket.

-

08-02-2011, 09:25 PM #11

I did see that other photo, it didn't look flash. I did wonder if the poster was being a bit harsh / picky but you don't have to search too far around the web to find people with similar issues. The other machine is 25% cheaper than the quick-cnc one though.

Your cabinet looks nice which is reassuring. I'm going to have to stop reading your posts though. It's making the waiting for my machine seem worse!

On the up side I might go and pick up the dust collection setup over the weekend which will give me something to play with. I can't use the dust collector on my current machine though, it'd suck the entire machine off the bench.

Cheers, Me.

-

08-04-2011, 12:53 PM #12

Dust collection pipe/hose

Total Trivia:

100mm solid PVC pipe is nearly as expensive here as flexible dust collection hose.

End result is that I was planning a cunning run of solid pipe along the roof of the garage, but I wont bother for the moment, I'll just get 6m of flex and run it up over the rafters and down to the router.

That's all I've got. :-)

-

08-08-2011, 10:32 AM #13

1 week into the wait, and a minor update. :-)

I had someone pay me in $US via paypal so I ordered some bits to go with the new router.

I got 2x ER11 nuts, 13 piece metric collet set, a few end mills and a dial indicator with magnetic mount from CTC Tools Home Page.

I also ordered a laser tacho from ebay for a bit of trivia pointing at spindle type activity while I'm getting used to the VFD and mapping the speed step settings in the DSP to actual spindle speed. In all honesty I saw a pic of someone playing with one on here and thought it'd be kinda cool to play with.

The dial indicator will come in handy for checking the table levelness and tram on the k6100a. That and it matched the balance I had in PayPal almost to the cent.

I've taken two trailer loads of junk out of the garage, and it's looking a bit more like I can fit the machine in. I've got to make some new shelves and cut a chunk out of an old bench to clear a bit more space, so that's next weekend's plan.

Cheers, Chris H.

-

08-13-2011, 10:37 AM #14

Progress...

On making space at least.

Busted out the rip saw and my 8 year old assistant / support table. That turned 65m of 75x30 ceiling battens into bits that sorta look like shelf framing.

The plan is for two 3 shelf units 2.4m long 400 deep. 600mm between shelves. Should give me enough flat space to get 90% of the junk off the floor and benches.

I used the shelves as an excuse to buy a router as well as my cheap no-brand one died about 5 months ago. Luck would have it that the Bosch POF1200 was marked down quite a bit at the local.

It's a nice router, but it's a heavy little sucker. Makes me appreciate more how strong some of the mdf routers on here are if they're able to swing one around.

I routed out a notch for the rails (justification for power tool purchase, ignoring the fact that I have a rip saw and chisels ). And stuck it together with long super screws.

). And stuck it together with long super screws.

Finished the shelves with some cabots super clear floor sealer I had spare from another project. That's to protect from enevitable garage spills.

Just need to make the second one tomorrow and shuffle stuff around to see if everything fits.

Cheers me.

-

08-18-2011, 10:50 AM #15

Progress...

Taney confirmed that the machine will be on its way Thursday next week, and I'm now registered with New Zealand customs as an importer so they can bill me for inspection, clearance etc.

I also got some mail from CTC tools today. The mail was delivered 3 days late due to us being snowed in. Our once a year snow fall this year turned out to be more of a storm. :-)

The collets are smaller than I imagined they'd be, but perfectly formed in their own tapered kind of way.

I also got the 4 and 6mm carbide end mills. Understandably I have now put the 6mm mill in the matching collet + nut and made router noises in my head.

CTC packed the bits really well, and they were sent registered mail that I could track which is how I know the snow delayed delivery.

At the same time our long suffering rural postie delivered the laser tachometer. That came from eBay seller cenyonline, airmail and well packed. Had a quick play with it and there's not much I can say about it... Does what you'd expect, and came with a pretty soft case.

On the down side some carbide engraving tools I ordered at the same time from another eBay vendor didn't turn up, and they're 1/8th so I could be using them now rather than making silly router noises in my head.

Cheers, Chris H.

-

08-27-2011, 12:23 AM #16

Update...

Replying to my own thread all the time, this is a tad sad.

Anyway, the k6100 got on the boat at Qingdao a couple of days ago and his now sailing at 32km/hr roughly due south about 150km off the coast of China in the East China Sea. It's going to stop off at Shanghai for a day to take on more freight and then it's a direct run to New Zealand.

Thanks to the cool that is AIS/APRS I can look up on the web where my router is. It's like track and trace but for OCD sufferers.

For the record the engraving bits turned up as well and I've been busy messing about with making key ring tags out of some acrylic sheet I scored.

Cheers, Me.

-

08-27-2011, 01:02 AM #17

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Congrats!

That pic of your 8yo helping is very cute Chris! My 8yo also loves heping out and seeing it working. Can't wait to see loads of pics of the machine when you get it.

I'm very happy with my JCut machine but second time round I'd possibly do it differently.

If yours is the same as Rockets, then that's very, very nice wiring and construction. The top especially looks very well thought out and constructed. I'd be curious to see photos of the underneath of the table and casting frame when you get it. Mines a "little" rough but functional. Although with the vibration and noise issues i've pretty much decided to change the entire top over to a slab of aluminium.

Post loads of pics mate! And let us know how much in the end, it all helps!

cheers,

IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

08-27-2011, 10:25 PM #18

Hi, lots of photos won't be a problem. :-)

The junior helpers can be good at times, although Mr 5 pretty quickly gives up on 'helping' in the shed if it's not for him...

I think the underside/frame is not cast on the quick units based on the pics I found online. It appears to welded steel? Will have to wait and see..

I've got the vacuum/t-slot table option which might mean a different design from the standard slotted deck.

Will post pics in about three weeks. :-)

The boat is just docking at Ningbo, just for the record. Must stop watching the arps website every 5 mins.

-

08-30-2011, 01:19 PM #19

Dust...

Picked up the dust collector today.

I got a smallish 750W job with the dual back type cyclonic setup.

It runs surprisingly quiet and sucks lots. What more could you ask for?

A well illustrated manual apparently. The English was fine to ready but the photos were terrible and it took quite a while for the kids and I to get the thing together. Although it might have been the kids slowing the process down some in hind sight. :-)

I figure most people here know what a dust collector looks like so attached are some pictures chosen purely for their aesthetic value.

-

08-30-2011, 11:38 PM #20

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Hey Chris,

What are the details of the dust extractor you got, and when you say it's quiet, how quiet do you mean compared to other power tools or appliances?

I've been on the hunt for a decent lower (500W-1000W) powered extractor that didn't make the dogs howl two suburbs away. 750W sounds good, but the noise level i'm very interested in, did they give the dB rating?

cheers,

IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

Similar Threads

-

Martys K6100A Adventure

By Marty989 in forum Australia, New Zealand Club HouseReplies: 18Last Post: 09-14-2011, 12:25 PM -

Kiwi junk-box mini router...

By kiwichris in forum CNC Wood Router Project LogReplies: 58Last Post: 05-30-2011, 12:14 AM -

Reading Spindle RPM - Quick K6100A

By SkipW in forum Chinese MachinesReplies: 3Last Post: 02-08-2011, 05:57 PM -

K6100A Table Mod

By SkipW in forum Chinese MachinesReplies: 1Last Post: 10-21-2010, 12:53 AM -

Hybrid build in the land of the metric kiwi

By jestah in forum Joes CNC Model 2006Replies: 6Last Post: 01-22-2009, 06:54 PM

Reply With Quote

Reply With Quote