I need to construct a gantry to move my Bridgeport mill around in the garage so I can eventually lower it into my basement.

I'm quite fond of this design:

A Frame Gantries Mobile Gantries A Frame Gantry Mobile Gantry provided by Lifting Equipment LTD

I would like a span of 3 meters and a liftcapacity of 2 tons, anybody have any idea about the dimensions of the I-beam and the square (vertical) tubing.

I can figer the I-beam out myself but I don't know about the square tubing that holds the I-beam up (dimensions and thickness).

If you don't wanna go public you can always send me a pm.

Thread: Gantry design

Results 1 to 13 of 13

-

09-07-2011, 09:02 PM #1

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 32

Gantry design

-

09-09-2011, 05:40 PM #2

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Well, if you're doing a simple analysis, you'd look at the normal stress in the legs caused by the load you're lifting plus the weight of the gantry beam. Then you'd calculate if the leg would buckle (search for column buckling). Don't forget to add a safety factor.

CNC mill build thread: http://www.cnczone.com/forums/vertical_mill_lathe_project_log/110305-gantry_mill.html

-

09-10-2011, 09:17 AM #3

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 32

-

09-15-2011, 09:29 PM #4

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 28

I found this discussion to be extremely interesting but after googling "column buckling" my head was left spinning. I can figure the forces on a simple beam. Say 4,000 pounds on a 9' beam gives you 18,000 pounds of force for the ends to support. But I kind of get lost with this modulus of elasticity and second moment of inertia, some formulas even used a quadratic moment of inertia, others a polar moment of inertia. But I dislike guessing about the necessary size also, so I would really like to be able to calculate this force accurately. I imagine a three inch pipe would be strong enough to support an 18,000 pound compressive buckling load but I don't want to proceed to use one until I'm sure the job wouldn't require a four inch pipe.

One formula I found was force equals pi squared times the modulus of elasticity times the moment of inertia divided by the length squared.

On my three inch pipe (figure 1/4" wall) I figured a moment of inertia of about 2 times pi squared times E gives me 19.73 times 29 million (modulus for steel) gives me over 572 million pounds. Dividing this by the length of the column (just for grins say 96") still gives me over 5 million pounds Obviously this can't be right. seems to me 5 million pounds would smash my 3" pipe into a flat little disk. I guess my question is what did I do wrong?

Oh wait the formula is length squared so that brings it down to 62,000 pounds. A much more comfortable range. It looks like the 3" pipe would be strong enough.

Could someone please check my math and tell me if I'm way off base or right on. My head is still spinning.

-

09-15-2011, 10:25 PM #5

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

I think you're confusing lots of different concepts. In your second sentence, I don't know how you get 18k lbs from 4k lbs, for example. If you have a 4k lbs vertical point load in the middle of a simply supported beam (supported at both ends), each end will have to support 2k lbs of the load.

You have to know that you're applying a formula correctly to be able to trust the results. There are always assumptions built in, and if your situation violates those assumptions reality might be very different than what you calculate. Since we're talking about lifting heavy objects, I'm a bit leery of saying more in case you squish yourself. If you want to read more, here's the book I used in school to learn this stuff: [ame=http://www.amazon.com/Applied-Strength-Materials-Robert-Mott/dp/0132368498/ref=sr_1_1?s=books&ie=UTF8&qid=1316121699&sr=1-1]Amazon.com: Applied Strength of Materials (5th Edition) (9780132368490): Robert L. Mott: Books[/ame]CNC mill build thread: http://www.cnczone.com/forums/vertical_mill_lathe_project_log/110305-gantry_mill.html

-

09-19-2011, 04:30 PM #6

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 28

I got the 18k pounds because there is a 4.5 foot moment arm between the load and the point of reaction at the end of the beam. 4.5 times 4k = 18k. That being said you are right that it would be 2k on each end and not 4k as I'd computed in my head.

The reason for my posting the question is so I can understand the forces involved better. I certainly don't want to squish myself. People are always telling me I'm building things way too sturdy. I would like to build lighter but I don't want a beam buckling on me either so I'm trying to get a better grasp on the subject. It sounds like you've been schooled in these concepts where I'm basically self taught. I've read a couple books on strength of materials. I'll look at the one you mentioned.

That being said does it look like I figured things out about right. Is the formula a good one for computing buckling loads on a post? (pi squared times modulus times moment of inertia all divided by length squared). the result I got seemed to show that a three inch, quarter inch wall pipe would be more than adequate. Not that I'm gonna build this thing mind you, but I want to better understand the process of designing an appropriate structure. When I do get around to building a gantry for my cnc machine I want to know I'm not pushing around excessive weight for the needs. I don't have access to fancy

FEA analysis tools so I'm gonna need to estimate the old fashioned way.

Thanks for the help and advice.

-

09-19-2011, 04:57 PM #7

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Yes, that formula will work if the slenderness ratio is greater than the critical slenderness (see Ideal Pinned Column Buckling Calculation and Equation - Engineers Edge). If the slenderness ratio is less, then you need Johnson's formula.

Your 18k lbs example is not really correct. You're confusing torque and normal force I think. If you start throwing torque on the leg to gantry beam joint into the mix, this all gets much more complicated.CNC mill build thread: http://www.cnczone.com/forums/vertical_mill_lathe_project_log/110305-gantry_mill.html

-

09-19-2011, 11:17 PM #8

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 28

Thanks for the link. I'll check it out. Yes I agree its very complicated. I would leave all this to the engineers but they want more money than I can afford. Maybe there's a good reason for that though.

anyway thanks for the help. I appreciate your feedback.

I am currently reading Statics and Strength of Materials by Bassin, Brodsky and Woldoff to try to increase my understanding of these concepts. I will look at the book you reccommended afterward. (its pretty spendy but I suppose a good book would be).

-

09-19-2011, 11:24 PM #9

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

I only recommend that book because it's what I used in school. It's a typical price for a book like that unfortunately. You might be able to find a used older edition which would essentially be the same but cheaper. Mine is the 4th edition.

CNC mill build thread: http://www.cnczone.com/forums/vertical_mill_lathe_project_log/110305-gantry_mill.html

-

09-20-2011, 01:51 AM #10

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 0

Try something like this: buckling - Wolfram|Alpha

-

09-30-2011, 12:46 AM #11

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 61

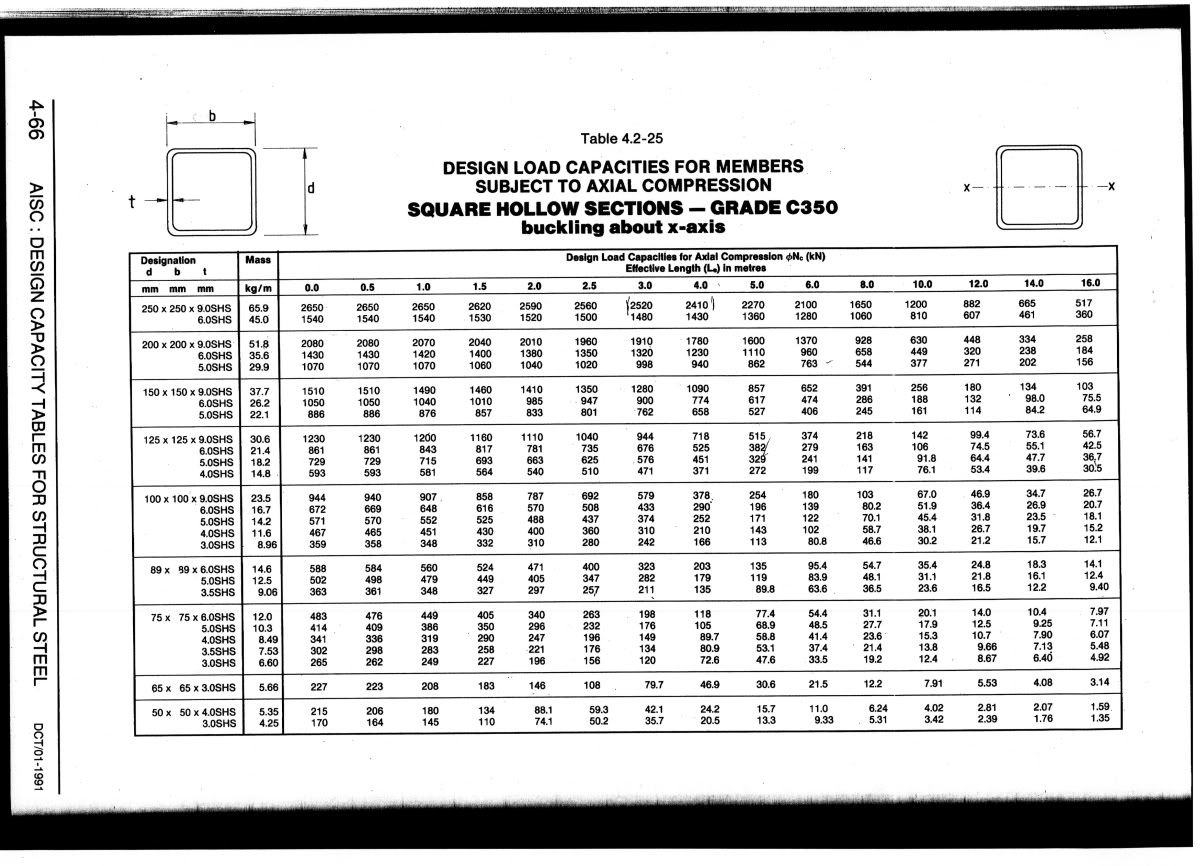

A simple chart out of a book I use most days

There will be some bending moment induced in the legs when you roll the thing, (couldn't even begin to guess what that would be though) so the combined bending and compression will lower the allowable compressive load a bit.

-

10-02-2011, 06:24 PM #12

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 102

You may want to reconsider doing these calculations on your own. This is far too complex to just figure out without a number of college level mechanical engineering courses. Your going to be moving around quite a bit of weight and one miscalculation could cause catistrophic failure.

-

10-02-2011, 08:50 PM #13

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

You should generally not be rolling around a gantry with a weight suspended from it. That's a recipe for disaster right there unless the gantry is specifically designed for this. You typically use a gantry crane to lift an object straight up and then set it back down. To move something, you lift the object, then lower it onto a low dolly, pallet that you can get a pallet jack in, truck bed, etc. Then you move the heavy item where ever you want using the dolly, move the UNLOADED gantry crane above it, then lift the item again, remove the dolly, and set the item down.

CNC mill build thread: http://www.cnczone.com/forums/vertical_mill_lathe_project_log/110305-gantry_mill.html

Similar Threads

-

Gantry: planning to design moving open gantry

By rdcd in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 11-14-2009, 10:52 PM -

Help with gantry design

By robe_uk in forum DIY CNC Router Table MachinesReplies: 6Last Post: 11-02-2009, 02:36 PM -

New design, gantry or something else

By Miguel- in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 01-26-2009, 10:33 AM -

GANTRY Design

By bert5604 in forum Waterjet General TopicsReplies: 3Last Post: 10-01-2007, 02:30 PM -

Gantry design???

By dmgdesigns in forum DIY CNC Router Table MachinesReplies: 1Last Post: 05-25-2004, 03:13 PM

Reply With Quote

Reply With Quote