This is the way I have done it. The Z Axis Direction pin# set up in Mach3 and going to the BoB or controller also connects directly to the TTL input shown in this diagram.

Does this help ??

Tweakie.

Results 41 to 60 of 97

-

11-11-2011, 06:18 PM #41

Member

Member

- Join Date

- Nov 2009

- Posts

- 707

CNC is only limited by our imagination.

-

11-11-2011, 10:17 PM #42

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Cheers for the input - I haven't got that far yet (and I suspect it might be a while before I do) but due to not having mach3 (and not really wanting to pirate it), I don't think mach3 is going to be good solution for me.

I'm also really looking for a simple solution as although I can probably handle the messing around with G-code etc, as it's probably going to be at my local Hackerspace ideally it wants to be as simple as possible.

LAOS really would be the ideal thing (although it doesn't yet have any raster function I'm sure that'll come) - just gotta wait for it.

After playing with the crappy software that came with the machine, I can live with it for a while and then look into replacing the controller board with something else next year.

I'd say I probably have as many mods to do as I've done so far so plenty to keep me occupied hardware wise.

-

11-12-2011, 03:01 AM #43

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 29

Mowcius,

I´m sorry to say it, but you won´t be able to even play with the crappy software/board. It is a crappy like you´ve said, and the only thing you gonna do are circles and squares shapes, period.

Think well about changing the board, your machine is being so good that deserves a decent board.

Raphael

-

11-12-2011, 03:18 AM #44

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

There's truth in that, I know the software's bad but next year's quickly approaching and I wouldn't be surprised if i've only just got around to cutting things by then!

One of the next things to do is get a custom air assist head made - I might be able to borrow a lathe and get one done next week or that might be a few weeks while I get someone else to make one for me.

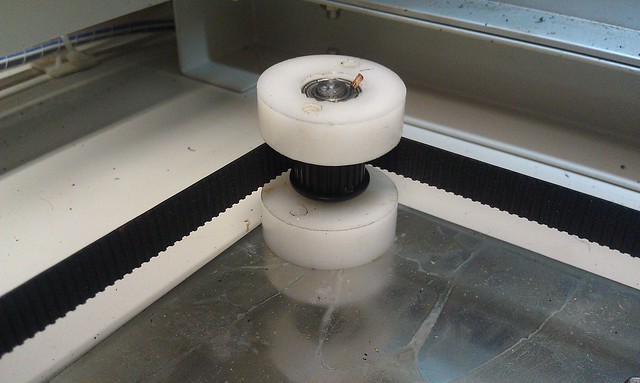

Also, has anyone got a good source of pulleys and belts in the UK for my Z axis height adjustment.

-

11-12-2011, 11:42 AM #45

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 146

diycnc.co.uk

Mechanical

technobotsonline.com

Technobots - Electronic & Mechanical Componentsrabbit / ls3040

-

11-12-2011, 11:54 AM #46

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

-

11-14-2011, 01:26 AM #47

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Another quick update today.

I made a comment and very quickly got a reply from the LAOS people about becoming a beta tester - purchase of one of their boards and the other components I need (excluding the parts I have already), it's going to set me back about £90. Far cheaper than buying an off the shelf system and as it's all open source on ATmega chips and ARM based MBED boards it'll be far easier to modify to my liking.

That looks like a good direction to go in as they've made a very positive start on the software with basic functionality up and running. Progress seems pretty quick and I hope to help in any way I can (I'll be doing quite a lot of work on the i2c based display/control panel myself).

I should have the money to proceed in that direction next week and then hopefully have the parts I need and mechanical laser stuff sorted a week or two after that.

Lasered parts by Christmas is very likely.

The lens saga still continues but I feel I'm getting somewhere now.

After informing them that the lenses cost at least $50 they told me they didn't as they sold them and they'd refund me $30.

I casually declined the offer, linking them to the only one I can find (for ~$65) and mentioning that if they sell them then they should be able to send me one.

Next they asked me to confirm I needed a 12mm lens and said they'd refund me $50 if they couldn't get me on.

I again, declined the offer, informing them they'd need to refund me the full amount if they couldn't get me a replacement lens.

Finally after confirming I needed 12mm, they said they'd do their best to find one or refund me "the money" (presumably ~$65).

Now I just wait...

After re-making the X track bracket, I see why the roller was at an angle, as the track's quite a way off level (would still be off with a bent roller). This will just be a simple matter of extending the holes I drilled slightly to level it off.

I still need to get my head around the laser carriage mount and how I'm going to attach the cable chain (on the other end as well).

Still seems like I have lots to do then but I'll try and make the most of my day off (today - maybe I should be sleeping) and get my arse in gear making things.

-

11-22-2011, 05:02 PM #48

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

Interested in this, as I bought one of these.

I should really go visit the factory and get them to make me one with the mods built in though. Maybe will have a chat to them and see if they'll make me a couple ( i'm in China, and I speak enough Chinese to be dangerous ).

).

Given that the ****ty Moshi board itself is about 500rmb, removing it cuts the cost of the machine by a 5th...

(they're about 2500rmb locally).

-

11-22-2011, 05:31 PM #49

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Sounds about right - 10:1 rmb:GBP. My machine cost ~£250 + ~£200 shipping, import etc (which was paid by someone else as thankfully my machine was sent from the UK).

I didn't realise the control board was such a large part of the price - I'm ripping mine out in about a week and replacing it with a LAOS laser board having never used the moshi board...

I have considered the possibility of trying to buy the machines as shells (or a larger/better machine as a shell) much cheaper then replacing the controller board and making some other 'minor' modifications and getting a good hobby machine which could still be sold on with some profit for £600-700 or so.

I have made some more progress on my modifications but not really enough to warrant an update.

I need to hassle the eBay seller about where my replacement lens is (whether or not they've sent one yet) and then with my machine almost working again (not finished all the mods yet though by any means) and my new controller board and parts on their way I should be cutting before Christmas (I hope).

-

11-22-2011, 05:41 PM #50

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

Yeah, thats my plan too (eventually).

For now going to be emc2 driven though (well, tomorrow once I work out how to interface it up to the cheap ass 5 axis card I bought to try)

Mine is the comment under yours at the Laos site hehe.

Going to blog my escapades here -

Chinese Laser Engraver modding « Computer Solutions Blog

-

11-22-2011, 06:54 PM #51

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Good to hear there are still people similarly inclined

I'll have to have a proper chat to you about it all at some point.

If you use IRC then I'm on many channels but recently set up an unofficial Laos room at #laos on Freenode which might be a good start. I'm normally on in the evenings (GMT) and weekends.

I see your laser cutter also seems to have the same lid catching problem as mine does

-

11-22-2011, 08:39 PM #52

I have one of these units sold by Full Spectrum Engineering in Las Vegas. Mechanically identical, but they've added a Z-lift table, air assist and a laser spot as well as adding on their own controller board and software. If anybody's interested in getting a closer look at any of the components, just let me know. (whitelightlaserengraving at gmail dot com)

-

11-22-2011, 10:21 PM #53

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Yeah I'd be interested in how they've gone about the Z axis - I suppose I'd be interested in all the things that are different

I presume their Z lift limits the bed size as most of them do with threaded rods inside the cutting area.

Posting the pics up somewhere public if you can would be better than email as then everyone can benefit.

I'm thinking of putting up a web page with a load of pics of variations/modifications done to this type of machine so if you do have lots of pics that you wouldn't mind being used (with attribution) then I'd happily accept them in an email.

-

11-22-2011, 10:28 PM #54

I currently have the Z-lift table off for a small modification to add downdraft ventilation, so I'll see what I can get in the way of pics tonight since all the mechanicals are open for inspection.

On my unit, the table is a solid 1/16" aluminum plate with 4 jack screws under it. The cutting grid sits on top of that. Unfortunately, I've been having issues with plexiglass parts cutting in that it builds up gases under the parts which explodes once in a while. The current mod should fix that. I may do a better Z-axis lift at a later time, but am also planning on building a much larger machine in the future as well.

-

11-23-2011, 12:14 AM #55

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 0

Yeah quite a lot of the machines are like that with a solid plate but ideally you need a honeycomb bed that's only supported at the edges to allow fumes and particles/small bits to pass straight through.

In Universal laser machines that I've used, I think there's some kind of substance below the honeycomb bed to absord the laser if it gets all the way through the material/runs over an edge and just goes straight through the honeycomb - anyone know if that's correct/what the substance is? Or just any suggestions as to what to put under the honeycomb?

Modifying this has been quite fun at times, annoying other times but I fancy building completely from scratch next year. I was thinking of a hobby 300x300 sized machine that could cater to the home fab market like the reprap does - the problem is the tube length - being about 800mm long (rough guess), the case has to be large... Unless it was floor mounted and the tube was vertical... But then it kinda goes against the desk unit hobby market idea.

Clearly more thinking required.

2 members and 7 guests viewing... This thread is becoming quite popular.

-

11-23-2011, 03:58 AM #56

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

[ame=http://www.youtube.com/watch?v=o4n6qz7BBgQ]laser cutter[/ame]

laser cutter

-

11-23-2011, 04:00 AM #57

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

I am a new comer

come here to know the environment ,

laser cutter

laser engraving machine laser cutting machine

-

11-23-2011, 06:21 AM #58

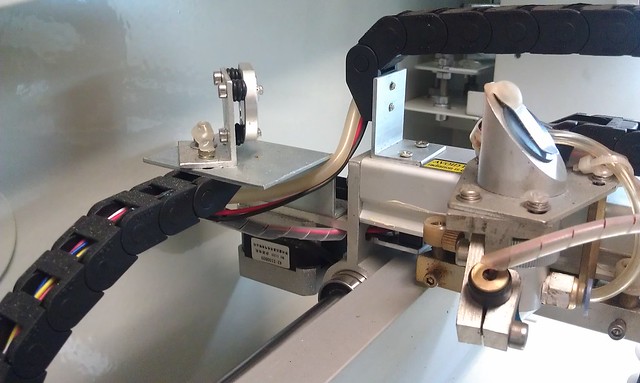

Z-axis table lifts.

Inside of 40w FSE laser with cutting table removed.

Flying head showing air assist nozzle and aiming dot. Note: piece of painter's tape with pinhole over coarser red laser produces super fine point.

Left end of gantry showing cable guides and X-axis motor

A few more shots at my Flickr page here:

FSE 40w Laser Photos

Yeah, I'm looking at probably redesigning the cutting grid. I got my downdraft ventilation going pretty well, but the laser seems to be making it down through the holes and still having enough focus to cause some slight damage. Looks like it might even kill the fan eventually, but at least the theory works. Been cutting plexiglass all night without any BOOM.

-

11-23-2011, 10:47 AM #59

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 329

Anodised aluminium acts like a "backstop" for the beam , it absorbs it.

You can lay a thin sheet down and elevate the acrylic you cutting off it for fume and melt clearance , just use some 10mm scrap blocks of acrylic etc. Honeycomb is a problem as you get flashback from it , often marring the back surface of items you cutting.

-

11-23-2011, 06:15 PM #60

I'm thinking of trying out a frame with fine steel wire (like the stuff from those cheap egg slicers) stretched across it instead of the aluminum cutting grid. It'd be far thinner, thus giving me some additional Z-height, and wouldn't cause the back of my parts to get flashed by bounce. If it works, it'll give everybody another option for supporting material.

Similar Threads

-

Cheap Laser Cutter/Engraver

By LucasGelf in forum Laser Engraving / Cutting Machine General TopicsReplies: 24Last Post: 03-06-2017, 02:34 PM -

Setting up a K40 (cheap chinese) laser cutter

By JackWilliam in forum Laser Engraving / Cutting Machine General TopicsReplies: 19Last Post: 07-27-2013, 08:37 PM -

Cheap chinese spindle modifications - Generic

By speedydumpster in forum Benchtop MachinesReplies: 1Last Post: 03-28-2013, 04:28 PM -

Honeycomb bed for cheap chinese laser cutter

By JackWilliam in forum Laser Engraving / Cutting Machine General TopicsReplies: 7Last Post: 11-24-2012, 09:11 AM -

DIY Laser cutter CHEAP !!!!!

By mexico.redsail in forum Laser Engraving / Cutting Machine General TopicsReplies: 50Last Post: 10-05-2010, 10:12 AM

Reply With Quote

Reply With Quote