day 29.2:

Got the photos of the molds for those x-ray castings, they don't look big but these are over 500lbs a piece

---------------------------------------------------------------------------

Some people have been asking me why greensand is called green if it isn't green at all. There is some debate between foundrymen and why greensand is called greensand, some say its because of the color, others say its merely the state its in(new, unused). Most everyone i've asked doesn't really have a definite answer, While this sand does look green, there is also many different kinds of sand; silica base, graphite, olivine that don't look too green. foundry work and molding dates back to before 3000BC so to really know why its called greensand, i couldn't tell ya.

Thread: Making a 671 Supercharger

Results 41 to 60 of 93

-

11-15-2011, 10:20 PM #41

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

-

11-16-2011, 01:42 PM #42

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

here is a short article i wrote back in May on our website discussing the difference in supercharger, most of you probably know this but i figured i'd share it anyways.

KB Results

----------------------------------------------------------------------

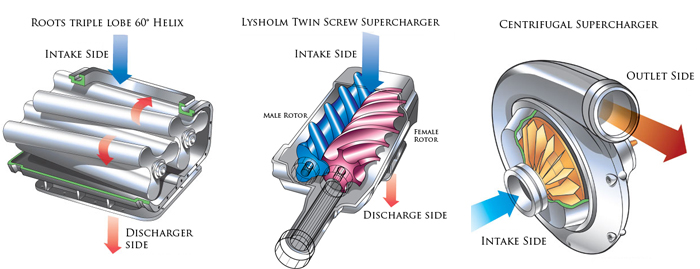

"Types of Superchargers and their Efficiency

There are three main types of superchargers in today's automotive market, Root style, Lysholm twin screw and centrifugal, each one suited for a different application. While there are more types of superchargers i am only going to use the three most common types in this article.

First we need to know what exactly a supercharger is designed to do, while most of you many know what one does or how it works i would still like to state that a superchargers job is to force a larger mass of air into the same amount of volume into a engine, i will explain later the emphasis on mass and volume.

The Lysholm supercharger is the newest in design of a positive displacement supercharger and is more efficient that the roots style. the reason they are more efficient is because of the way they compress the air into the intake. Speaking in terms of physics, When ever u move, smash, compress anything, whether it be a solid, gas or liquid it causes the molecules of the substance to heat up, which causes the volume to expand but u still have the same amount of mass. For superchargers, the hotter the air gets the less you will have density wise going into each cylinder. So while a roots spin outwards towards the casing wall smashing the air as it spins and is then forced and compressed within the intake manifold, the newer twin screws has a male(blue) and female(pink) rotor that spins the air in between its rotors and much more fluidly, moving the air from the front to the back, compressing the air while it is still in the blower, reducing the friction and resistance caused by the air, reducing the heat as it enters the cylinders.

A centrifugal supercharger is nothing more than a turbocharger that is driven by the engine instead of the exhaust system, centrifugals work by spinning multiple blades and very high RPMs(much higher than roots or twin screw) to force air into the intake, they are much more efficient at high rpms compared to roots or twin screw but they lack low rpm boost and create much more heat.

A simple example of boost loss would be if you where to install a boost gauge in you manifold and block off the intakes, then heat the manifold from 70°F to 150°F the gauge would actually register an increase in boost, although obviously its not running any boost and you still have the same amount of air in the engine.

The faster you spin a supercharger the more it will heat up the air and the more the volumetric efficiency will drop but the boost will still show an increase. If you can build an engine to actually withstand it, you could theoretically spin a supercharger so fast and heat the air so much it would actually become parasitic to the engine. (I don't recommend that)

On the reverse side of intake modification, take an engine that runs NOS. NOS is used in high performance engine for short duration to temporarily increase hp, it works by being injected into the intake system and does two things, one it super-cools the air and two, when the nos enters the combustion chamber and reaches 296°C the nitrogen and oxygen atoms split releasing more oxygen so the air becomes more dense thus you are able to pack a larger mass of air into the same amount of volume.

You might be thinking though if u take a large 1471 blower and throw it on a engine you can spin it slower than a smaller 671 and still get the same amount of compression and since it is spinning slower it wont produce as much heat, and your right but you have to factor in the extra weight and resistance that the engine has to push, the heavier your components are, the more hp it will take to drive the supercharger."

-

11-16-2011, 02:42 PM #43

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

Fantastic thread and really enjoyable photos! Thank you for that!

I have a question regarding shrinkage, if that is ok with you. I know in some home foundry attempts at casting aluminium shrinkage can be a big issue.

Since you are using a very refined professional setup, what shrinkage did you get on the blower casing (ie what shrinkage was compensated on the pattern)? Like to get a 12" aluminium casting how much larger would you make the pattern? And is shrinkage the same on smaller casts compared to large casts like the blower casing?

The nearest foundry here was 70 miles away, but there is now a local foundry and I was considering cutting some patterns on my CNC machine to cast some motorcycle cosmetic parts.

-

11-17-2011, 02:03 PM #44

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Its really hard to get shrink perfect, ever casting is different and also depends on a lot of factors; metal temp, greensand, airset, permenant mold, investment or diecasting, how big your cores are and where they are located, wall thicknesses gas in the metal. most older guys will say 1/8" per foot, which comes out to 0.01041%, or scale your part to 100.01041%, doesn't sound like a lot but it is. Another way to look at it is 1/8" shrink would be about 0.010" per inch or ten thousands per inch. i believe we used twelve thousands per inch or 0.012(100.012%) on the blower so i just took the 15.3x1.0012=15.3183"(its actually a lot easier in CAD software, u just hit scale and put in 1.0012

). Again though ever casting is different, we pour a permanent mold here that is a 35" compound bow and it only shrank 0.009" while the mold maker gave it a 0.0011" shrink(he's been a pattern maker and mold designer for 45 years), the only way to get good at it is trail by error.

). Again though ever casting is different, we pour a permanent mold here that is a 35" compound bow and it only shrank 0.009" while the mold maker gave it a 0.0011" shrink(he's been a pattern maker and mold designer for 45 years), the only way to get good at it is trail by error.

older pattern guys will usually tell you a fraction per foot while younger guys usually like % or thousands per inch just because its easier to keep track of on there computer models.

-

11-18-2011, 11:37 AM #45

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

Thank you very much Dzuari for the information!

My friend sells small cosmetic parts for motorcycles and that 1% shrinkage may not affect them too much. It's still really good to know a ball-park figure so thank you for that.

-

11-19-2011, 11:23 AM #46

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 66

I just wanted to say thanks for posting these pictures and descriptions. I am watching with eager anticipation!:cheers:

Machinists do it with greater precision and less tolerance!

-

11-29-2011, 04:13 AM #47

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

this video is just about how cores and coreboxes work in casting a part, it is not the final video of making the supercharger, im just using this build to show how cores work.

[ame="http://www.youtube.com/watch?v=0rU2aohquj4"]Cores & Coreboxes - YouTube[/ame]

-

11-29-2011, 04:34 PM #48

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Day.... 40 somethin

:

:

housings are back from heat treat, Mazak guy is in working with our maintenance men trying to get the 500 up and running. Keeps faulting out after a tool change. As soon as we get a scrap one we will send it to X-ray out for lab testing, Which may or may not be this batch. i do however have some photos and of the other xray job along with lab results of tensile and yield, poured from the same furnace, ill post those in a bit.

----------------------------------------------------------------------------------------------------------------------------------------------------------------

Video of how cores work:

[ame=http://www.youtube.com/watch?v=0rU2aohquj4]Cores & Coreboxes - YouTube[/ame]

-

11-29-2011, 07:53 PM #49

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Day 45ish.2:

Here are the X-ray of the castings we poured out of the same furnace that the blower where poured. These and the blowers are A356.2-T6, A356 is the metal, .2 is referring to its state and T6 is the heat treat type.

This casting past xray, the photos where taken after heat treat. if there was any defects, you would see black spots in the photo which would be gas bubbles or porosity within the casting.

I've also blocked out certain info in the photos, we don't release any confidential information of customers or vendors unless we have permission to do so.

-----------------------------------------------------------------------

This photo is of the chemical composition of the metal.

-----------------------------------------------------------------

This photo is of the Tensile, yield and elongation.

------------------------------------------------------------------------------

Now, for those of you who might not know, tensile strength is a measurement of force applied upon an object when it is being pulled apart, other forces of measurement can be compressive and shearing.

Yield strength is a measurement of the force required to permanently deform an object. The closer the yield point of a substance is too its tensile, the longer it will hold its form but once deformed it will quickly break.

rubber bands is a good example, you can pull a rubber band and stretch it very far, but once elongation stops, it will break soon after any more force is applied on it, so its tensile strength and yield strength are almost one in the same.

-----------------------------------------------------------------------------------------------

Here is a photo of solidworks standard for 6061-T6, most commonly used billet alloy.

--------------------------------------------------------------------------------

Now, even though solidworks uses this standard for 6061-T6, it does not mean a blower made out of it will have these results, every casting is different and the section you test will dictate its results. Theoretically speaking though, lets say we have a blower made from A356-T6 and 6061-T6 from the results above, how do they compare?

Ignoring elongation, the A356 blower will have a wider range between deformation to failure while a 6061 will hold its rigidity 2,561psi longer but soon after deformation it will fail, but remember, tensile is a measurement of something being pulled apart, not compressive or shearing, which would be rotors pushing against the housing.

-

11-30-2011, 02:28 PM #50

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Just to let you guys all know what you do for this build, we check our site traffic every week, these last two dots are the days after i released the "Cores & Coreboxes" videos. This way i'm able to show the top brass(my dad

) how the videos affect our site traffic then he lets me make more videos and build more things for you guys to watch. So thank you for the support.

) how the videos affect our site traffic then he lets me make more videos and build more things for you guys to watch. So thank you for the support.

-

11-30-2011, 11:36 PM #51

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 603

Just to let you know Big D, Still watching so keep it coming

-

12-01-2011, 03:13 PM #52

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Here is what happens when a coreprint breaks in the mold and the core shifts during casting. This casting was machined, and a few thousands more and some bad things would have happened inside the CNC.

This castings is a actually a roller for an automated greens mower being developed by a company called Precise Path, we have been doing the casting and machining for one of the rollers on it. my uncle, the one that owns the shop that i made the blower pattern in, designing and made the pattern and corebox for this.(core break was a result of a bad core, not the tooling)

Here is a video of the thing, you can see this roller at 0:39 of the video, its the small one between the bigger front and rear rollers.

http://www.youtube.com/embed/vY9u1ZgOiMM

-

12-01-2011, 08:54 PM #53

Member

Member

- Join Date

- Aug 2008

- Posts

- 406

Are you going to machine rotors soon would like to see that..? thanks

-

12-01-2011, 09:39 PM #54

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Just to let everyone know, i am finishing up on the first part of the video, everything i have shot since the start of the build, just need to do some commentary and minor editing and it will be ready to upload, hopefully by tonight.

-

12-01-2011, 10:31 PM #55

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

-

12-04-2011, 11:25 PM #56

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 481

GM6-8-10-14_71 blower sizes

Hi , Once again beautiful workmanship and great to see from idea to actual machined castings

Are you just concentrating on the 6-71 size or are there plans to do the full series of the GM6-8-10-14_71 blower sizes ?

cheersFor Sale - ( Melb, Australia ) Heenan & Froude G490EH Engine Dynamometer. High Speed /Horsepower rating

-

12-05-2011, 03:44 AM #57

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

-

12-05-2011, 03:45 AM #58

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

Here is part 1 video of making the supercharger

http://www.youtube.com/embed/zU34no3VLHI

If anyone wants to help us out, feel free to share the video on any other forum

-

12-05-2011, 02:05 PM #59

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 603

-

12-05-2011, 08:01 PM #60

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 104

thanks, there will definitely be a video of it on some cars. I'll also be videoing all the test we will be putting it through.

-----------------------------------------------------------------------

Grab one of the adapter plates and decided to get it machined, don't have an intake to show you how they lay on and weld down but here is machining it and the after (without bolt holes)

---------------------------------------------------------------------------------

Machined it on a bridgeport. thought i took a picture of cutting the other face but apparently my phone didn't feel like working.

--------------------------------------------------------------------

Done

-------------------------------------------------------------------

I ended up having to take off 0.005" for the finishing cut to keep it from flexing or moving. It might not look like a clean cut but a lot of the marks are from sand stoning it afterwards.

Similar Threads

-

Making a Z gib for X3

By binfordw in forum Benchtop MachinesReplies: 11Last Post: 08-24-2010, 05:07 AM -

Supercharger design

By Machine09 in forum I.C. EnginesReplies: 8Last Post: 09-19-2009, 07:34 PM -

supercharger

By metalhack in forum I.C. EnginesReplies: 3Last Post: 03-04-2008, 09:31 AM -

Making M2

By pekeX in forum MetalWork DiscussionReplies: 0Last Post: 04-06-2007, 01:47 PM -

Axial Flow Supercharger

By devincox in forum Hobby DiscussionReplies: 25Last Post: 03-09-2007, 09:01 AM

Reply With Quote

Reply With Quote