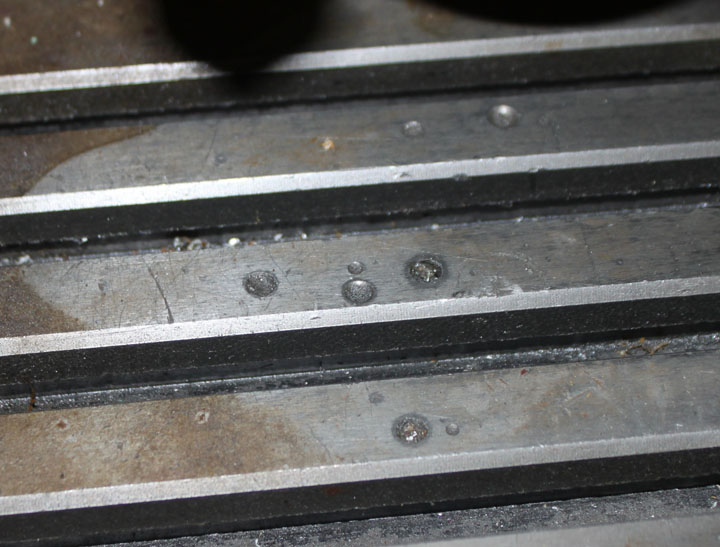

I bought a used mill that is in otherwise good shape, but has some holes in the X-Y slotted table where the previous operator went too far, as shown in the picture below.

My idea is to fill it with JB Weld and sand it smooth. Anyone have a better idea?

Thanks,

Thread: Filling some holes

Results 1 to 9 of 9

-

11-06-2011, 10:48 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 499

Filling some holes

"72.6 per cent of all statistics are made up on the spot." - Steven Wright

-

11-07-2011, 12:02 AM #2

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3206

Since there's more than one, I guess stamping OIL next to each one could be confusing....

Since what you want is truly cosmetic, JBWeld, Devcon, or some kind of epoxy with cast iron in it would probably be just fine.

Clean the holes and degrease them well, and let the base casting dry well first.

I'd just flat-file it and get back to work.

-

11-07-2011, 02:16 PM #3

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 143

I'm with Fizz here. They don't affect the capability of the machine. Remove the high spots (if they haven't been removed already) and make some chips. If you are busy with that machine, you'll, eventually, add some blemishes of your own.

-

11-07-2011, 02:44 PM #4

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

Using lacquer thinner to clean the area you want anything to stick to will help a lot with the bonding. No drying to worry with either, blast of air and its ready, and even thats not needed.

I would get something better than JB though, some of the marine epoxies might be good(Slash Zone from Z-Spar is good).

But I have to agree, knocking down any high edges and getting on with it would not be a bad thing either. All though I willl have to admite, it would bother me if I had to look down at my table with holes in it.

Ofcourse you could machine/grind the whole table. Or drill & plug it with a slug of cast iron and then machine/grind. If you do epoxy be carefull of sanding down to far and causing a low spot around the spots. r

JessGOD Bless, and prayers for all.

-

11-07-2011, 04:02 PM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 499

Thanks for the replies - You're right, it is just an appearance issue, and I thought about just letting it go, but when you first get the machine and you are setting it up and making it true, you want it to be as nice as possible, because in my experience I will probably never feel quite that way again about it.

So, the main thing is not to make it worse by a botched file or grinding job. Definitely don't think drilling, tapping, and grinding is worth it, although probably the optimum fix. I guess I'll just fill her up with epoxy.

Just wanted to make sure some smart cookie out there (and there are several of them on this forum) hadn't come up with a better idea.

Thanks again."72.6 per cent of all statistics are made up on the spot." - Steven Wright

-

11-07-2011, 04:23 PM #6

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

like fizzit said flat file it then use it, I would use a big stone and stone it, ( broken grinding wheel)

if you epoxy it, the epoxy and steel have different heat/shrink temps so you might end up causing more problems than its worth. what happens if its chips? epoxy is just a a bandaid and will look like it. either do it righ IE weld it or just leave it alone.

I can guarentee you if your not happy with the holes the epoxy will drive you up a wall after a while. so why waste the time?

Delw

-

11-07-2011, 04:58 PM #7

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3206

I understand the embarrassment of a table with divots in it. Fortunately, there's some bandaids that are functional, or at least pretty available to you.

(I'm thinking this is a manual mill? If CNC, slightly different approach)

If they're where you're going to have your vise live, they'll be covered over. (btw, your vise should wander from one side of the table to the other, and back, so the ways and lead screws wear evenly. Never just bolt it down and leave it)

Even on a brand new manual mill, I'll put a clean rag next to the vise on the table for the cutters, files, etc., for the job. On a CNC, you can mount a small tooling plate over the divots...real handy for flat parts.

If you're having company in the shop, there's always the ultimate tasteful decoration for any self-respecting mill....the doily. Moms love 'em!

Table Lace, Doilies, Lace Table Runners, Placemats, Dresser Scarves

...or for that durable, long lasting classic feel that's compatible with everything we're getting out of China these days....there's plastic doilies..!

Vintage Plastic Doilies Three of Them Tupperware on eBay!

(and what better to rest your coffee cup on to avoid unsightly stains and rings?)

-

11-07-2011, 05:43 PM #8

Registered

Registered

- Join Date

- May 2004

- Posts

- 402

I bought a much abused Bridgeport years ago as it was all I could afford at the time. Ways needed grinding, new screws - you name it it needed it! Table was like a piece of Gruyer cheese. I got a specialist cast iron welding outfit to plug all the slots and holes before having it ground. Ended up with a good flat table but you can still see the repairs. Patina it's called !

Andrew Mawson

East Sussex, UK

-

11-07-2011, 09:03 PM #9

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

you know if you leave those holes in that table fill them with different cutting fluids Ie one for oil, one for tap fluid, one for coolant. then when you drill small holes in parts using small drills you have your choice of oils to use with out looking all over the shop for it. I mean just a thought LOL

I have had my hand mill for 20+ years it has one small hole made by me, never bothered me to this day and yes I put concentrated coolant in it and just touch the drill or reamer.

Delw

Similar Threads

-

Filling the voids

By Drools in forum DIY CNC Router Table MachinesReplies: 17Last Post: 09-27-2011, 01:47 AM -

Filling wood

By tyskkvinna in forum WoodWorking TopicsReplies: 1Last Post: 01-30-2010, 11:45 PM -

Filling....

By 2A-TB@ThePatch in forum Laser Engraving / Cutting Machine General TopicsReplies: 3Last Post: 12-22-2009, 11:34 PM -

Filling holes on magnesium wheels?

By PeeBee in forum Casting MetalsReplies: 1Last Post: 01-21-2007, 11:53 PM -

Filling machine time

By zachf in forum CNC Machining CentersReplies: 3Last Post: 04-06-2006, 01:50 AM

Reply With Quote

Reply With Quote